|

| LS4 / F40 swap - fieroguru (Page 203/216) |

|

fieroguru

|

NOV 17, 10:02 PM

|

|

Another weekend of some WOT runs!

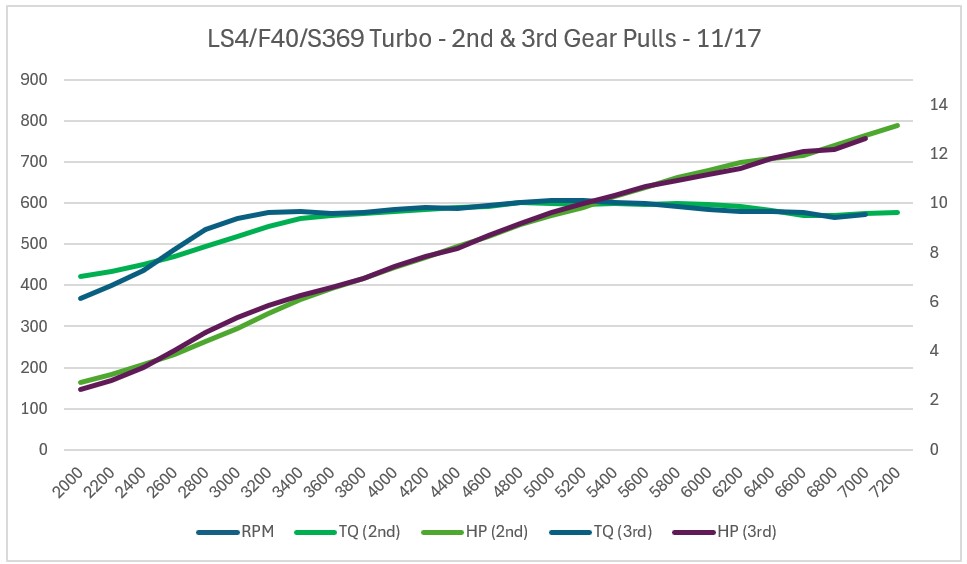

I wanted to do a WOT run in 1st, 2nd and 3rd so I could compare them.

1st gear is pretty much wheel spin city. If I floor it, wheels spin, and I hit the rev limiter. Peak boost was 6 psi.

2nd gear - if I floor it at 2000 rpm, the rear tires will fight for traction but they hold - peak boost was 7.3 psi. If I floor it in the 3K to 4K range, wheel spin city. The road had a pretty good crown, so once the tires lit up, the rear started to creep to the right side.

3rd gear - hammer down, tires hold, and you rocket to 120+ mph.

Now granted, the tires are 8 years old and past their prime. It also was about 65 degrees, so cooler than the tires really would like. I am planning to buy some new tires next spring.

The E40 has a table where I can slow the opening rate by gear, but not sure it will be enough. This car really needs some kid of boost by gear and/or traction control (or awd).

Also learned that if I press the clutch right before the 7300 rpm rev limited, the engine will overshoot the 7300 rev limit.

Peak RPM: 7560

Peak Boost: 8.0

Peak TQ: 608

Peak HP: 768

There wasn't much of a difference between the power curves between 2nd and 3rd gears.

As we head into winter, I have a rather significant upgrade for the car - probably in the January time frame.

https://www.haltech.com/pro...bel-ls-suits-gen-iv/

While on the HRPT this year, I spent some time talking with a sales rep at Haltech. They impressed me with all the built in features (wideband closed loop, boost control, boost by gear, traction control, flex fuel, cruise control, etc. I picked up the Rebel LS and harness several months back, but wanted to fully vet the E40 before going aftermarket.

|

|

|

FieroWannaBe

|

NOV 20, 06:42 PM

|

|

I recently acquired the same unit.

Let me know what you figure outnas far as the VSS. They limit the number of teeth to 50.

I think the pulses per mile input will still work though.

I also hope you are able to set the timing offset with the LS4 timing cover. (I will be using the an LS7 cover).

|

|

|

fieroguru

|

NOV 20, 08:12 PM

|

|

| quote | Originally posted by FieroWannaBe:

I recently acquired the same unit.

Let me know what you figure outnas far as the VSS. They limit the number of teeth to 50.

I think the pulses per mile input will still work though.

I also hope you are able to set the timing offset with the LS4 timing cover. (I will be using the an LS7 cover). |

|

Good to hear others are taking the plunge as well.

I was planning to add a reluctor ring to one of the front wheels, so I can do the same for the rear. I wanted the front one to enable traction control, but haven't looked too deep into it to know if it will work with just 1 input from each end of the car.

I switched from the LS4 timing cover to the LS2 one with the last round of upgrades, so no concerns with that.[This message has been edited by fieroguru (edited 11-20-2024).]

|

|

|

Rickady88GT

|

NOV 24, 11:51 AM

|

|

Awesome work man, thanks for the details.

|

|

|

fieroguru

|

NOV 24, 04:14 PM

|

|

I finished up the work on Sara's Christmas ornaments for her co-workers:

Here they are after being cut out:

Here are the finished pieces: Sara will add some ribbon to the hole for hanging on the tree.

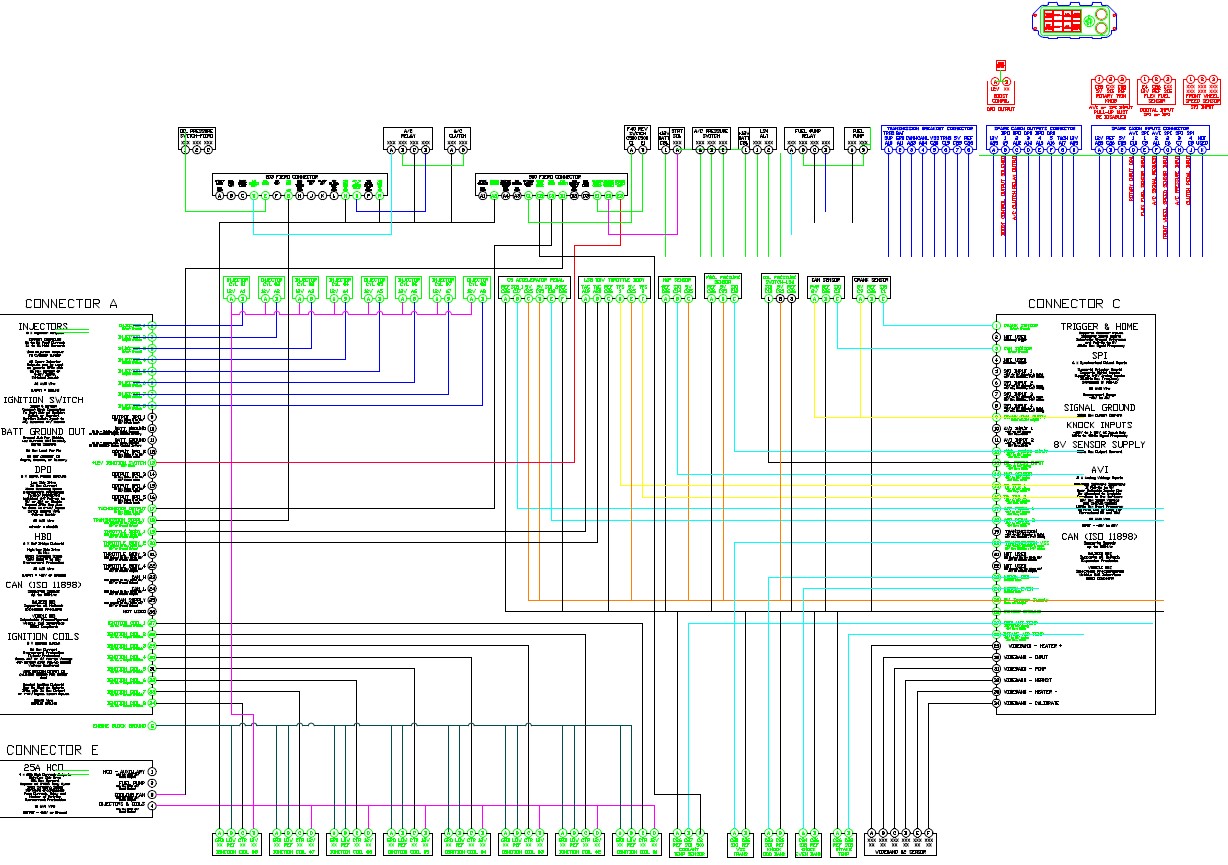

Also started on the base tune for the Haltech ecm.

Spent a couple of days checking out the software while the ecm was plugged into the laptop.

Started assigning the I/O for Cruise, Boost Control, Traction Control, and some of the 203/500 connections.

Of the the things I am not a fan of is the universalness of the harness, as to accomplish this, the added jumper harnesses (that can be changed based on the application), but that means there are a lot more harness connectors than there needs to be and will add unnecessary bulk to the harness. When the time comes, I will make a new harness that eliminates all the unnecessary connectors.

|

|

|

fieroguru

|

DEC 01, 06:39 PM

|

|

It was a long cold weekend so I decided to spend some time messing around with the Haltech harness.

I attached all the proper sub harnesses and then started drawing the wiring schematic for it as well as all the Fiero "integrations". Still have quite a bit more to do, but things are starting to get organized.

Here is the harness with all the sub harnesses attached and everything wire tied so I can roll it up for storage. Everything is about 2-3 times longer than it needs to be for a Fiero application, so it will be de-pinned and completely reworked in my typical fashion. This harness is anything but tidy...

I also picked up a couple of other Haltech parts. One is the 2 x 4 CAN Button panel and the other is the 12 position rotary switch to allow switching between various tunes for theft prevention, valet mode, and various level of boost.

https://www.haltech.com/pro...-haltech-can-keypad/

https://www.haltech.com/pro...-rotary-trim-module/

Here is a mock up of the panel for the old radio location. It will have the button panel, the rotary dial, and some USB charger ports. Still working on refining the use and placement for the available buttons.

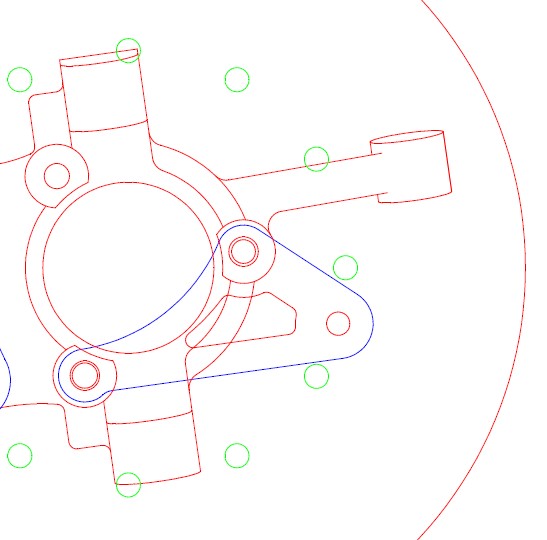

Also started pondering the front wheel speed sensor. Since I switched to 2 piece front rotors, the nuts on the backside should work as good trigger points. This will be 12 per rotation, 851 rotations per mile, 150 mph = 425 Hz switching rate. At 15 mph it will switch 42.5 times per second.

To mount a sensor to pickup the nuts, I am thinking a bracket like this one should work until my custom front knuckles and wheel bearings with ABS sensors are complete (1-2 years out).

Also, started the car up in the garage and let it run about 15 minutes to keep the battery charged.

|

|

|

fieroguru

|

DEC 14, 04:07 PM

|

|

I logged about 6,750 miles on the car this year, which is pretty good. With the temps staying below 40 degrees, I am ready to pull the drivetrain for the new harness/ecm and a few minor changes.

Before I pulled it, I wanted to get the front wheel speed sensor figured out. Here is the final setup (still need to paint the bracket). I used 88 caliper bolts for 2 of the wheel bearing bolts to allow for the threads to protrude on the backside to hold the bracket. Since the rotor hat bolts were longer than the nuts on the backside, I double nutted them with locktite and then put the rotor in the lathe to turn everything smooth.

|

|

|

ericjon262

|

DEC 16, 06:48 PM

|

|

|

did you not end up using the fabricated knuckles? they could be built to accommodate a WSS, or a hub with an integral WSS. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

I invited Lou Dias to trash me in my own thread, he refused. sorry. if he trashes your thread going after me. I tried.

|

|

|

fieroguru

|

DEC 16, 09:27 PM

|

|

Those are backburner for now and likely will be reworked when I get the cnc mill up and running.

They only work with the power steering rack and I haven't worked through all the details for it.

I am wanting to minimize the downtime for the car and not have it off the road for another 3 years, so the simple bracket and hall effect sensor won out for now.

|

|

|

fieroguru

|

DEC 21, 04:45 PM

|

|

While I did start disconnecting stuff to prepare to drop the cradle, I ended up purchasing a load cell for my cherry picker to get some weights before and after.

From the grain elevator scale, the rear was 1660 lbs. With the load sell it is showing 1526.5 lbs. This is with the rear wheels off the ground, but the lift point is about 8" behind the rear axle. If we account for that, the rear weight on the load cell would be 1656.0, which is close enough. I will be able to use use this load cell to determine how much weight I am able to remove/add with the next round of work.

I also ran the coilover spring adjusters all the way down, lowered the cherry picker so the rear wheels were touching, left the rear springs loose, and measured the sprung rear weight. The load cell shows 1346 lbs and accounting for the lift point, it would be 1460. This means the unsprung rear weight is about 200 lbs.

Been doing a lot of searching for intercoolers, found a few that I think will fit, so I will cut up some cardboard in the shape of them for test fitting before the drivetrain comes out. I would like to commit to the intercooler, its placement, and have some temporary brackets completed before I pull everything out. I will also make some fixtures so I can locate the pass through opening in the firewall and the haltech ecm placement to speed up the process of building the new harness.

|

|

|

|