|

| Applying wooden edgebanding to a full 360° radius. (Page 1/2) |

|

maryjane

|

FEB 22, 11:14 PM

|

|

I have a little maple tabletop I've been playing with... making it for daughter-in-law. She was pretty exacting in what she wanted it to look like and what it was to be mounted to for a base... I got it cut out to a perfect circle, strong backed to prevent warping or bowing, and I'm down to edgebanding it.

Nice and smooth and ROUND now.

I cut 2 pieces of maple banding on my tablesaw to a thickness of 3/16 and 78" long each (a good bit longer than the circumference of the table). Ran a pine board thu my planer to get a good flat surface, then using double sided tape, stuck the banding down on the board and decreased it's thickness to just under 3/32".

I have had problems in the past, steaming or soaking wooden edbanding to make it pliable enough to make it round without splitting out. The problem I had was not ggetting the wetorsteamed banding around the radius. The problem came when it dried out before the glue set. As it dried, it shrunk in overall length and left an opening..a vertical seam.

I currently have both pieces rolled up to about a 24" circle and my table top is 19 !/2" diameter.

I am not going to use contact cement. Too unforgiving if I make a mistake and I would have to chip the banding off in liitle pieces, probably damaging the tabletop in the process. Using Gorilla carpenter's glue. I have a metal strap clamp made to hold the banding firmly down around the top.

What's the chances of applying the banding to the radius raw..with no steam or soak and it not split or crack?

(I've put lots of edge banding on in another life but I had a pretty expensive machine to help back then..it even applied the glue and perfectly did the cutoff at the end)[This message has been edited by maryjane (edited 02-22-2022).]

|

|

|

GT-X

|

FEB 23, 07:38 AM

|

|

|

|

OldsFiero

|

FEB 23, 07:48 AM

|

|

| quote | Originally posted by GT-X:

I always use this. |

|

Same here. Always had good results.

MJ, if you want to make it totally from scratch my only advice would be to make it thinner. Say under 1/16 and avoid the water.

Marc

|

|

|

maryjane

|

FEB 23, 10:49 AM

|

|

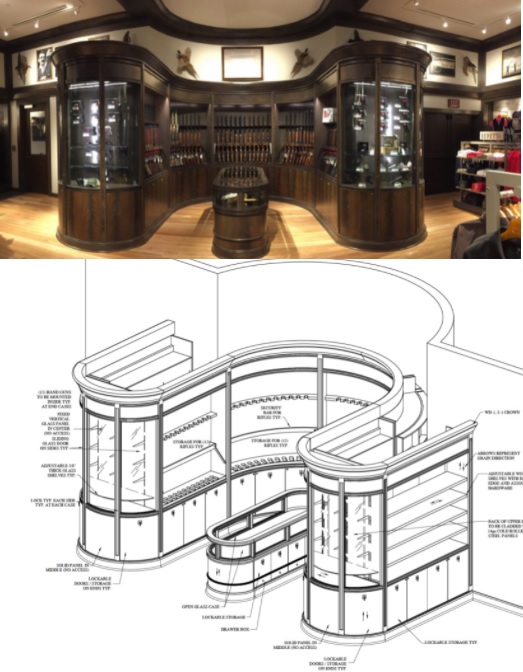

Where I worked, (Fixture Concepts San Angelo Tx) we only used 'off the shelf' banding if it was for manmade counter tops with vertical or standard surface and edgebanding on fixtures that had formica or were melamine, but we also cut many thousands of feet of real wood banding for store fixtures in upperclass 'fancy' stores and executive office furniture. The cheap 'plastic' stuff was for Home Depot, Eckerd Drugs, Home Depot, Lowes, and other retail type stores and general office furniture. I cut and applied quite a bit wood banding that was 1/8 using an edgebanding machine.

Something like this would get real wood.

Retail bigbox store fixtures would get the laminate banding because it was durable and cheap.

|

|

|

cliffw

|

FEB 23, 11:28 AM

|

|

| quote | Originally posted by maryjane:

I have a little maple tabletop I've been playing with...

|

|

That's not maple, is it ? Maple laminated maybe ?

If it is / was maple I would just router it.

|

|

|

maryjane

|

FEB 23, 11:34 AM

|

|

| quote | Originally posted by cliffw:

That's not maple, is it ? Maple laminated maybe ?

If it is / was maple I would just router it.

|

|

Router what?

And yes, it's raw unstained maple. That's what maple looks like before it gets the coloration you see in chairs and dining room tables.

This is what it will look like once it gets stained.

(She wants it to match this maple chair)

Bottom of the same chair. You can see a bit of the original raw coloration where the stain and varnish has peeled and faded.

[This message has been edited by maryjane (edited 02-23-2022).]

|

|

|

Jake_Dragon

|

FEB 23, 11:41 AM

|

|

| quote | Originally posted by maryjane:

Router what?

And yes, it's raw unstained maple. That's what maple looks like before it gets the coloration you see in chairs and dining room tables.

This is what it will look like once it gets stained.

(She wants it to match this maple chair)

Bottom of the same chair. You can see a bit of the original raw coloration where the stain and varnish has peeled and faded.

|

|

I think what he is talking about is just rounding off what you have. If it is solid maple and not laminated top then just router the edge to make it look nice.

It appears that the wood has some splintering, I do not recall having that issue with maple before.[This message has been edited by Jake_Dragon (edited 02-23-2022).]

|

|

|

Zeb

|

FEB 23, 12:02 PM

|

|

Make a jig of LESS THAN 19-1/2 inch Inside Diameter.

Steam the Edge Band and put it inside the jig, suitably clamped as required.

Once it dries, it should come out as a tight fit on the table top.

Glue it on, it should hold itself in place until you trim the ends and get clamps on if.

|

|

|

Mytime

|

FEB 23, 12:22 PM

|

|

I think it needs to be edge banded to cover the bracing he has on the bottom of the table.

I agree with Zeb but don’t think it needs to be clamped to a form. Steam it, curl it up smaller than 19 1/2” and let it dry.

|

|

|

maryjane

|

FEB 23, 12:34 PM

|

|

Real maple from mill cut board is quite 'hairy'. I'm guessing the maple you used came from a retail or wholesale hardwood supplier. In that case, it would have been lightly run thru a planer to remove the roughness and true it up. Much like plywood that either comes rough, one good side, or 2 good sides. This came seasoned, but straight from a mill. The reason maple is sued so often in dining room furniture is because of it's strength, the fact that it can be bent, stained from light to dark (it takes stain really well) and because of it's grain and ability to joint together without showing much seam.

This picture shows 2 pieces of maple. The bigger one is a drop left from cutting 4 pieces to do the glue up I did to make the round tabletop. The smaller piece is a tablesaw cut off I did of that same board.

This is what she brought me to mount the top to when I finish it.. you can see one of the pieces of banding rolled up behind it. The little side table to the left btw, is also maple but a completely different stain on it from her chairs or my dining room table. (It's one of several crap collector pieces of 'furniture' I have)

Why? Both the chair and the old milk can were her grandfather's (he was a dairy farmer) and she wanted to make use of the can, sitting between 2 maple chairs in her hallway..

Zeb and Mytime are correct. There is a seam between the maple top and the pine backing boards. That wasn't supposed to happen as the original pieces of maple were 1 1/4" rough cut thickness but it became necessary.

More explanation forthcoming..[This message has been edited by maryjane (edited 02-23-2022).]

|

|

|

|