|

| 48V automotive standard (Page 1/5) |

|

Wichita

|

MAR 03, 11:57 PM

|

|

I don't know if anyone here watch or even had interest in Tesla's Investor Day. I watched the whole thing live and was absolutely floored. Tesla is so far ahead of any other automotive manufacturer it isn't even funny.

But the one thing they brought out was the push for a 48V automotive architecture as the electric standard, instead of the 12V. I found that fascinating.

Not just for Tesla's sake, they made a shout out to the entire automotive industry to move to 48-volts.

Interesting if they make the difference and getting this standard to switch. Tesla said CyberTruck, Optimus and next gen 3 will all be 48-volts system.

|

|

|

RWDPLZ

|

MAR 04, 12:18 AM

|

|

Everyone has wanted to go to 48V for years, Elon has even discussed it before, but nobody wanted to be the FIRST to do it. Why? Because you would effectively be funding the R&D for all the parts required, that will be produced by your Tier 1 and Tier 2 suppliers, and then quickly made available to your competitors.

Going to 48V substantially reduces weight (a HUGE thing for EV's in improving range), and reduces the amount of copper needed to build the car, the cost of which has been steadily increasing for several years now.

|

|

|

theogre

|

MAR 04, 12:39 PM

|

|

Just More Tesla/Musk Hype...

36V/48V (BatteryV/ChargingV) have been pushed Years ago and never happen. Search in archives here or search @ Motor and other "Trade Rags" for vehicle service people.

Uses Small Wires?

Maybe for some things but a lot of other things must Stronger and other Heavier to handle this power.

Way Over Simplified Example: You pull a live 12v plug and get a small spark... do same on 36/48V and get a bigger spark. Bigger sparks "eat" the contacts Faster.

Most know Fiero PW switch burning problems... Use same switch on 36/48v and will fry a lot faster often in weeks to months not years.

Every switch and relay need to be heavier to handle higher volts to start with and because is 48 DC Volts that is harder to control Contact Arcing.

And often isn't simple to switch to "Solid State" Relays etc to replace old types. SS control can cause other problems. Is why most "fuse boxes" on newer vehicle have many standard relays in them even tho the circuit is controlled by PCM BCM etc.

LiIon etc may be lighter then Lead Batteries for cars but have there own problems like hates heat or cold where Lead batteries still work and charge as normal.

Lead Batteries Doesn't need BLM and more to work or will died or worse burn like Lithium can. LiPo may be "fire proof" but still die and fast When BLM and other protection fails.------------------

Dr. Ian Malcolm: Yeah, but your scientists were so preoccupied with whether or not they could, they didn't stop to think if they should.

(Jurassic Park)

The Ogre's Fiero Cave

|

|

|

Wichita

|

MAR 04, 02:32 PM

|

|

I wouldn't call it Tesla hype, because they already committed to it and already producing it.

They also are producing their own electrical modules and not waiting for the legacy auto suppliers to do anything.

Every article I've seen suggest that the 48-volt standard is far superior to 12-volt.

I wouldn't bet against Tesla. I understand that people are extremely locked in to old technology and ICE cars, but it isn't the future.

As much as people want to fight this, unfortunately your ICE horse is going to retire in your lifetime. All auto manufactures are pot committed to go all full EV and with that, I would bet my left nut that 48-volt standard follows along side it.

Every brand and model will be EV by the end of this decade if not sooner. Just look at the EV lineup that GM is coming out this year. Every brand they have and model will be EV. Ford same, Stellatis same.

|

|

|

82-T/A [At Work]

|

MAR 08, 11:54 AM

|

|

| quote | Originally posted by RWDPLZ:

Going to 48V substantially reduces weight... |

|

Can you explain this comment? Is it simply because the single battery in a car can thus be smaller, or is there something about pushing the higher voltage ... means that electronics within the car require less capacitors, smaller transformers, or something? (totally reaching here)

|

|

|

Jake_Dragon

|

MAR 08, 12:39 PM

|

|

|

When I first saw this I was trying to figure out how they would fit that many valves in an engine.

|

|

|

RWDPLZ

|

MAR 08, 01:53 PM

|

|

| quote | Originally posted by 82-T/A [At Work]:

Can you explain this comment? Is it simply because the single battery in a car can thus be smaller, or is there something about pushing the higher voltage ... means that electronics within the car require less capacitors, smaller transformers, or something? (totally reaching here) |

|

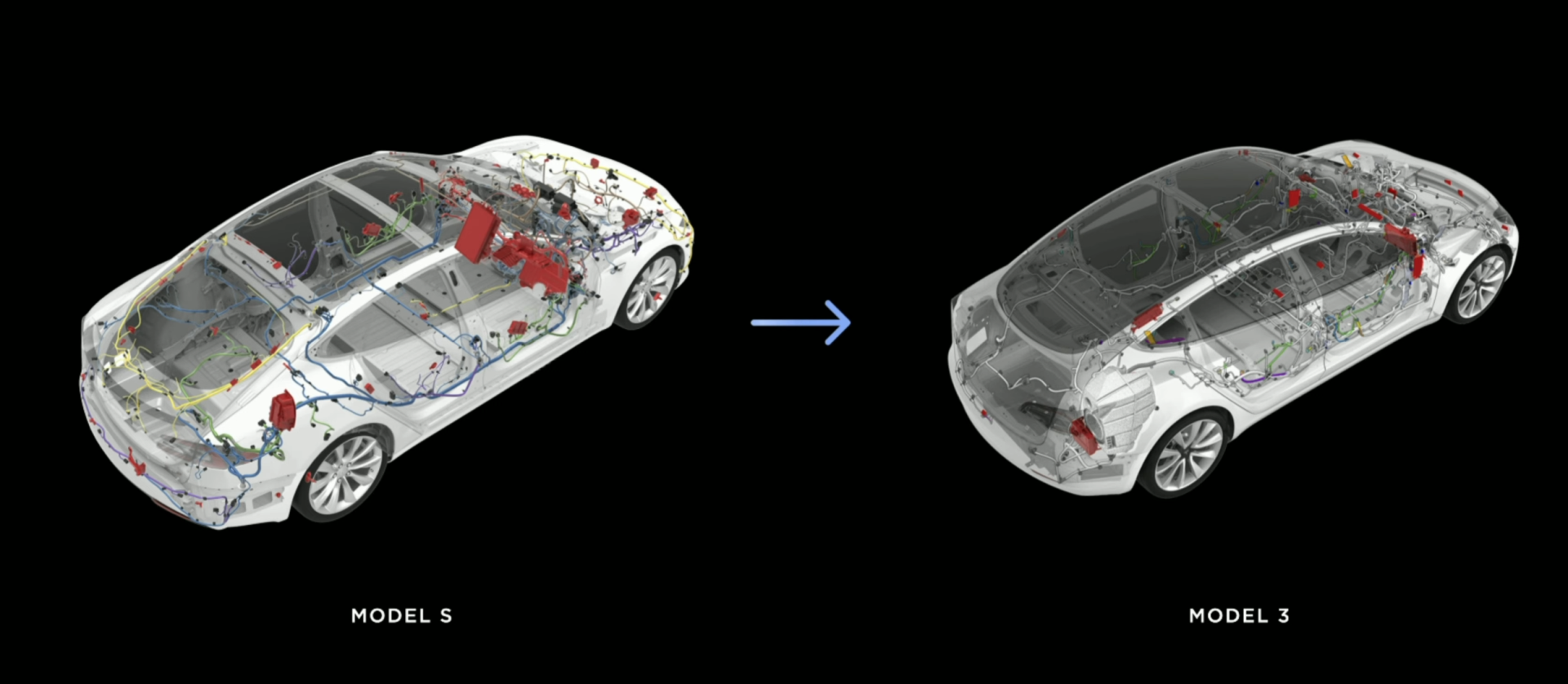

Cars contain a wide variety of wire sizes to run different circuits, depending on the current required for the devices on that circuit. The larger the load, the larger the wire CSA. Things like blower motors, window motors, lock solenoids, wiper motors, etc. It all adds up. With a 48V system, the higher voltage allows you to use smaller CSA wires for the same systems. Wire harnesses weigh a lot due to all the copper and tape, primarily. With EV's, every ounce counts.

Ohm's Law: Voltage = Current * Resistance

By increasing voltage from 12 to 48, you decrease current for the same load (resistance). Smaller current, smaller wire size required.

The part of the recent Investor Day video dealing specifically with wiring:

https://www.youtube.com/wat...1zEzVUV7w&t=1h19m19s

Sandy Munro in the past has also benchmarked the substantial improvement to the wiring used in Tesla vehicles since 2012.

https://www.youtube.com/watch?v=hY9cxyvUu6I

Typical modern vehicle wiring:

2012 Tesla Model S and current Model 3:

|

|

|

Wichita

|

MAR 08, 02:19 PM

|

|

| quote | Originally posted by 82-T/A [At Work]:

Can you explain this comment? Is it simply because the single battery in a car can thus be smaller, or is there something about pushing the higher voltage ... means that electronics within the car require less capacitors, smaller transformers, or something? (totally reaching here) |

|

It's the wiring size, weight, efficiency of devices and space savings.

"Engineers have consistently predicted that cars would shift from 12-volt electrical systems to 48-volt systems for two decades. But cost and inertia have kept 12-volt electrics in place, with the occasional targeted application of 48-volt power in high-current applications.

But the age of 12-volt-free vehicles is finally imminent, according to Tesla's vice president of hardware engineering, Pete Bannon. “One of the changes that we're looking to make right now is to change something that's been steady for the last 60 years: 12 volts,” he said at Tesla’s annual Investor Day conference.

“With Cybertruck and all future Tesla platforms we'll be moving to 48 volts,” Bannon announced. “This reduces the current needed by a factor of four. And since power loss in the harness is resistance times the square of the current, a four-times reduction in current leads to a 16-times reduction in lost power while distributing energy in the car. That allows for smaller wires smaller e-fuses and smaller controllers. That also allows us to make the heat sinks smaller or in many cases remove [them] completely, benefiting the car in terms of mass and weight.”

|

|

|

theogre

|

MAR 08, 03:44 PM

|

|

| quote | Originally posted by 82-T/A [At Work]:

Can you explain this comment? Is it simply because the single battery in a car can thus be smaller, or is there something about pushing the higher voltage ... means that electronics within the car require less capacitors, smaller transformers, or something? (totally reaching here) |

|

I can answer most of that but takes longer. So in a Very Short Story...

This started w/ 36v battery ("exact" is ~ 38v = 2.1v per cell on 18 cell lead battery.) and 48v to charge that via 48v alt of some kind pushed by many just ~ 20 years ago.

vs.

12 battery (12.6v = 2.1 V out of 6 cells) w/ 14.7v alt in "12v" systems.

Why?

Is directly related to my Cave, Electric Motors covering low volt problems.

Example: Most "small" E-motors spec Watts like many Starters are rated ~ 1.5KW... Battery V at full charge

1500w / 12.6v = 120 amps

vs

1500w / 36v = 42 amps

So the battery cables could be lighter because have to handle less amps. 36v Lead Battery itself can be lighter too pushing close to same weight for many 12v batteries because doesn't have to make ~ 3x the amps. Stater Motors could by lighter too at lest the windings.

But Switching 36/48v is another issue... The Starter Solenoid and allot more switches and relays are harder to make and cost more because the higher DC Volts have bigger arcing and "eats" the contacts faster, way worse then contact burning on "12v" systems. Switching DC Volts is always harder and burn more then same volts on AC power. Is why you often see a switch etc "stamped" like 250VAC 10A but 28 or Less VDC for same or less Amps.

More read note 1

People forget to disconnect the battery... If you pull a plug on 12v system like say C500, this often won't kill the pins... Doing same on 36v/48v can destroy them. Even faster like plugs handle more power sim to 84 Fiero C500 and others carrying alternator wires on 2 pins.

This is why no-one really tried to replace "12 systems" in the past.

Tesla et al can put 36v or 48v output on main battery set for PW and other things pulling a lot of power but have same switching problems.

You could use Solid State switches on everything but that cost in several ways even if was cheap = or < equiv "normal" switch and often needs heatsinks etc too and may not have space or airflow. That is part of Why Fiero ECM often die.

Telsa et al could use Bushless motors for PW etc but BDC motor + controls to make switching power easier cost more money even now and most "Bean Counters" would kill that plan.

Note 1: Many whine about 240VAC vs 120VAC for general power in a home etc. All of them ignore at best having 240VAC to run light bulbs and other things have same problem trying to switch the higher volts. Even the Breakers in main Breaker/Consumer Box have to handle the higher volts and have way more Arc protecting in them or will burn out very fast. Big Clive, John Ward and other real experts on YT have taken apart UK Breakers for consumer units showing the anti arc feature they have to use to stop burn out in a few cycles tripping them. JW also covers old UK home wiring often still found in use now in homes built before just 20-30 years ago depending what thing(s) shown.[This message has been edited by theogre (edited 03-08-2023).]

|

|

|

Wichita

|

MAR 08, 05:04 PM

|

|

| quote | Originally posted by theogre:

Note 1: Many whine about 240VAC vs 120VAC for general power in a home etc. All of them ignore at best having 240VAC to run light bulbs and other things have same problem trying to switch the higher volts. Even the Breakers in main Breaker/Consumer Box have to handle the higher volts and have way more Arc protecting in them or will burn out very fast. Big Clive, John Ward and other real experts on YT have taken apart UK Breakers for consumer units showing the anti arc feature they have to use to stop burn out in a few cycles tripping them. JW also covers old UK home wiring often still found in use now in homes built before just 20-30 years ago depending what thing(s) shown.

|

|

I've seen so many new commercial construction actually go towards 480VAC, with just about any high-voltage appliance running off if it at 480 volts.

Mainly I thought that the whole 48-volt standard was because that is typically the allowable limit for Safe Low Voltage SELV, or someone being at risk of electric shock and probably going into different classifications and wiring if you go above that voltage.

|

|

|

|