Lately there have been several discussions about replacement T-Top end caps, and the problems associated with having them reproduced.

I am in the group with broken end caps, and I would have willingly paid for a new set, IF they were available. Actually I did recently buy a new passanger side "B" pillar cap from mrfiero although I did not need that one, but it was available.

Being tired of having rattling tops when they were in, one night while laying in bed, I had an idea.

I took my car and my new end cap to my machinest and told him what I had planned, which was a bushing to mount to the steel reinforcement, and protruding through the end cap.

After some measuring on his part and a quick discussion about using brass vs aluminum, we decided that the brass would be more friendly to the locking action the end caps provide.

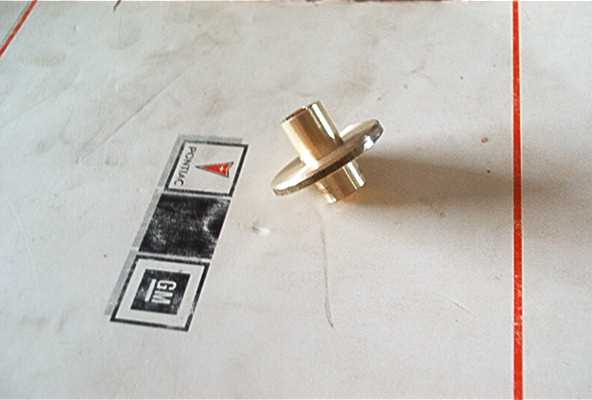

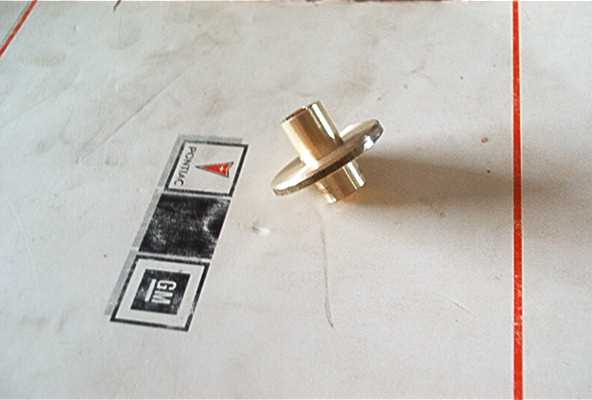

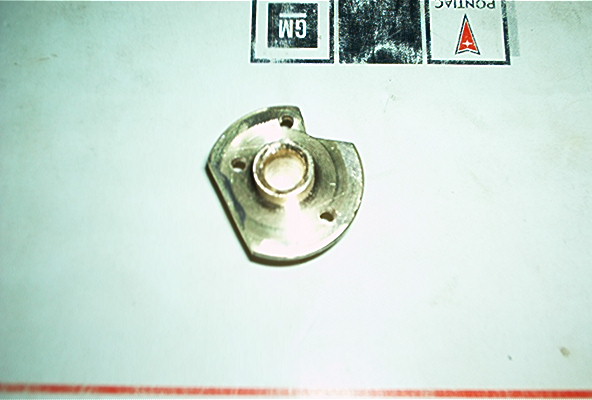

Today I stopped by the machine shop and picked up my goodies. I had 2 of these made, my rear pillar caps are fine for now.

The first thing I did was took the end cap and shaped the broken hole to allow the bushing to pass through. Sorry, no pic of this.

Picture of the drivers end cap removed. That nasty brown stuff is remainants of the old headliner and glue. I decided to replace the 2 original rivets that held the reinforcing plate to the car at this time.

Holding the bushing up in place for a test fit. Using my trusty sharpie I marked 3 locations for mounting holes then traced a few areas I wanted to remove to allow clearance for the trim cap and one of it's mounting screws.

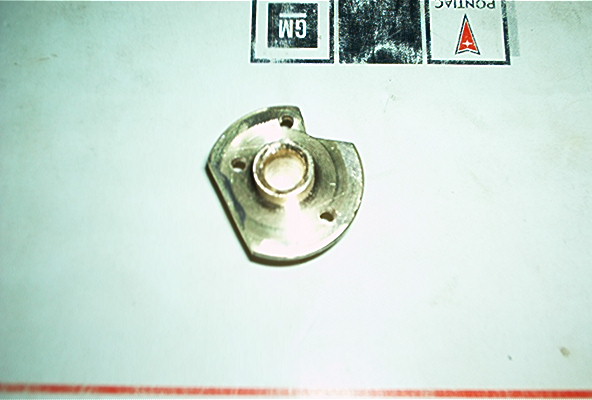

The bushing trimmed and mounting holes drilled. I also tapered the leading edge of the hole for the locking shaft to pass through.

I placed the bushing in position, then installed the end cap over it, and again with the sharpie, I traced around the excess that protruded through the hole.

This I cut down then proceeded to rivet the bushing in place.

Feeling confident on my project, and being after hours working at my own car, I treated myself,