| | | quote | Originally posted by Jordan Warkentin:

Question 1: What is a reluctor?

Question 2: How am I measuring it?

Question 3: Why am I measuring it?

|

|

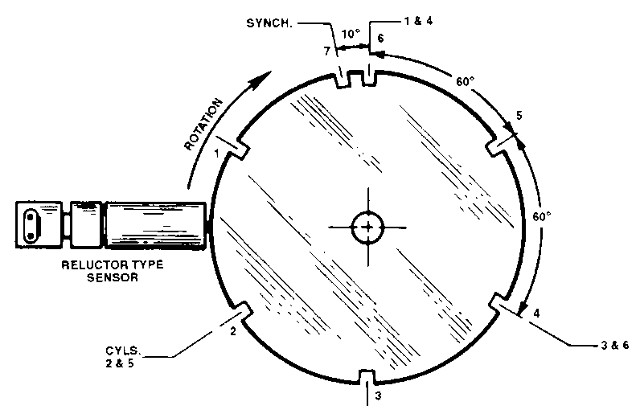

1) A

reluctor is simply an object that provides a path for a magnetic field to follow, just like a

conductor provides a path for an electric field to follow. In the case of an automotive crankshaft, the reluctor ring is there to work with a (magnetic) crankshaft position sensor.

2) "Position the crankshaft by measuring from the engine block to the first cut of the double notch on the reluctor ring. The distance should be 1-11/16 inches. If it isn't, turn the crankshaft until it is. Position the measuring ruler on the backside of the reluctor ring and measure from the first notch to the engine block"

3) The balancer assembly has to be properly phased with respect to the crankshaft to be effective ... just like the camshaft has to be properly phased vs. the crankshaft for the valve timing to be correct. Measuring from the block to the notches on the reluctor ring is similar to using the marks on the timing chain sprockets when you install a camshaft.