I flush the condenser, evaporator and tubes individually and replace the compressor hoses with the muffler, OT and accumulator. Don't even try to flush them nor the compressor (although you can drain the compressor, fill it with new oil, rotate it a bunch and drain that back out.) I flush everything backwards from the direction of flow and capture the flush and inspect it. It can tell you a lot. I take them out of the car but you can do it in the car if you are diligent.

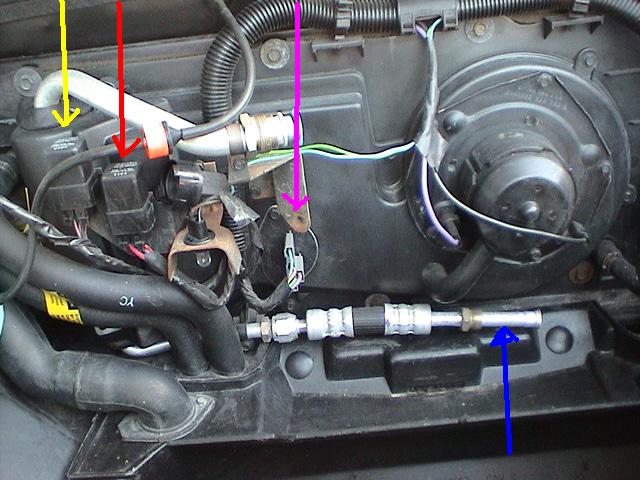

The short section of line with the OT can be flushed but again, install a new OT. Short end goes towards the evap.

The evaporator is a challenge to flush since it's a parallel flow design but it's generally protected from debris by the OT screen. The condenser is the first item to catch the debris from an exploded compressor but since it's a serial flow design you will have more success flushing it. Again, capture the flush and see what comes out of. When you blow air through the evap, it won't hold any pressure. If you are shooting air through it and it appears to hold pressure it's clogged. Consider this too, if you are going to this much effort, consider removing the evap and cleaning all of the leaves and dirt from it. You can really ensure it's flushed, and have a nice and clean evap on the outside for all of the cooler air you will be making!

I follow each flush with 30 minutes of 90 PSI air. I start with 5 minutes of using my finger over the outlet of whatever I am flushing to build pressure and then release it to allow the built up pressure to force the flush out (and any debris). Yep, five minutes of cover and then release. Then I blow 90 PSI air through continuously for 25 minutes with paper towels on the outlet so I can see what else comes out. If you have access to compressed nitrogen that is even better since it lacks the moisture of compressed air. With compressed air you need to vac the system longer to get the moisture out. It doesn't come out as easy as you would think.

When I vac, I pump it down for 4 hours and then let it sit for 2 and then repeat that a couple of times. Yeah, it takes awhile. You will get more moisture out though. I then let the system sit for 4 hours with the final vacuum, confirm it doesn't leak and start the charge procedure.

About the OT: I suggest you use only the stock white OT. Don't be tempted to put a yellow or Ford Blue in there. If the AC warms up at a stop, consider a pusher fan on the front of the condenser.

There are no short cuts with AC repair. Ask me how I know!

Did the compressor die or did you just get a leak?

Finally, go to this forum and ask lots of questions.

http://www.autoacforum.com/categories.cfm?catid=2[This message has been edited by TK (edited 07-12-2008).]

.JPG)