OR how to become Master of your Clutch.

Search Keywords: Clutch Problems, Clutch issues, Clutch not working, Grinding gears, Clutch engagement, Bad Clutch, Air in slave, Air in clutch,

Thought it would be nice to do another educational post on how the Clutch Master Cylinder works. There are differences between the two models used on the Fiero but the following statement is true for either one.

Remember this rule while you read:

................................for any model master, if the volume of fluid returning to the master cylinder when it is release

............................... is less than what left the master cylinder, you run the risk of air entering the system.

Many problem with the clutch not working are blamed on the slave.

Many owner have replace the slave in an attempt to resolve their clutch problems without success.

Hope this thread will explain why. I believe a lot of money has been wasted replacing slaves when they are not the problem.

A bad slave really can only has one problem.

1. A leaking piston. (fluid leaking out. )

Air leaking in a clutch system cannot be cause by a slave cylinder unless it is also leaking fluid. Read on to see why.

If you eliminate fluid leaking out of any part of the clutch system then the problem has to be the Master cylinder.

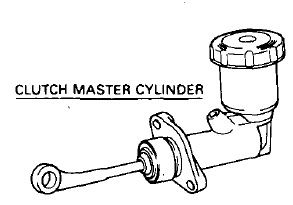

First lets start with a look at a common Master Cylinder. This is the Girling Model used in most early Fieros.

Here is a master just setting. There are only two main parts.

1.The large main piston that transfers the fluid to the slave

2. The small spring loaded fill valve.

At rest the fill valve is open and fluid is allowed to enter from the reservoir if needed. This should only happen if there is a loss of fluid in the system or the small amount of wear that ocurrs on the clutch disk.

Now as you start to step on the clutch peddle the piston starts to move into the bore. If you have the reservoir cap off this is when you see the little flow of fluid show up in the reservoir. This ocurrs until the fill valve contacts it's seat covering the fill hole.

No fluid is pushed to slave until the fill valve is closed.

As the piston continues to move the fill valve spring compesses increasing pressure on the fill valve and fluid is then push to the slave actuating the clutch.

When the clutch peddle is released the process is reversed and the fluid will flow from the slave back into the master cylinder.

Then fully release the fill valve re-opens and any lost fluid is replaced from the reservoir,

LEAKS.

There are really only two places for the master to leak.

If the fill valve spring is weak, seal is bad, or crud is on the seat fluid will leak back to the reservoir as the peddle is pressed.

This problem will not show a loss of fluid but just causes malfunction of the clutch

This type of problem would manifest itself as:

Slave not extending all the way. (grinding when shifting into gear while stopped)

Clutch slowly engaging while the peddle is held down.

Not being able to shift into gear.

Grinding while shifting gears. ( can also be from bad syncros)

Finding air in the system all the time.

Bad piston seal.

This will normally show up as lost fluid which will collect under the dust cap or run down onto the carpet.

If you are loosing fluid from the slave or master this is another way that air can get into the system and increase your problems.

If fluid is lost, as you start to release the clutch peddle the fill valve has not opened to allow fluid to enter from the reservoir. Once all the fluid has returned from the slave and master piston contunes to move the system would begin to develop a negative pressure due to the difference in volume due to the leak. (until the fill valve opens) During this window of time air can be pulled into the system past the slave or master piston.

This could account for some that have stated that they keep bleeding air from their slave but they keep finding more.

Fluid leaking past the fill valve could also cause the above to occur since the system fluid volume would be reduced until the fill valve re-opened.

My 85 clutch master had started to leak down while I had the clutch pushed in. This was resulting in the clutch engaging if you had it in gear and holding the peddle down. If you held it down more that 10 sec. you could not shift into any gear since the clutch was already engaged. This is a result of the fill valve leaking the fluid back to the reservoir. I happen to have another master that had seals that look to be in good shape so I pulled the one out of the 85 and took it apart.

Here is the piston from the master.

Here is the fill valve. In this case the seal was rotting away from age allowing fluid to leak back into the reservoir causing the clutch problems.

This is a pic of the fill hole that the seal covers in the bore.

"New" parts in and it was put back into the car. Now to bleed.

I first tried a normal brake bleed method as a test. Other have said this does not work. I would agree due to the explaination above. If you open the slave bleeder, push the peddle down, close the bleeder and release the peddle you have changed the volume in the system and when you releae the peddle will suck air into the system.

Next I tried the hose on the bleeder into a bottle with fluid in it. Opened the bleeder and pumped the peddle. Some air came out but still net enough. Still only had 1/4" slave movement.

HOW TO POWER BLEED YOU CLUTCH SYSTEM IN SECONDS.

Power bleeding would work much better. Now what would be a simple way to power bleed by yourself that anyone could do.

Answer... very simple...

Took out the bleeder and put grease around the threads to seal them from air getting in.

I put my hose and bottle on the slave bleeder and have the bleeder the highest point in the system.

Filled the reservoir and replace the cap.

Grabbed the can of dust off from the shelf.

Pressed it to the air vent hole in the top of the master cap and gave it a shot of "air". (about 1 sec. then check level)

Lots of air came out of the slave. (since I had rebuilt the master)

Removed the master cap and had emptied the reservoir. The neat thing about doing it this way (this point is important -> ) is if the cap bellows is good (no holes) you will only push fluid out until the bellows bottoms in the reservoir and then it stops since your not using much pressure.

Filled up the reservoir and repeated the above four times. Not more air and had clean fluid coming out.

Closed up the bleeder and tried the peddle.

BTY what I use to caught the fluid from the bleeder is a wine bottle. (you have to drink the wine, not a problem)

Use some 1/4 plastic tubing used for drip watering systems that you can get at any home supply store.

Drill two 1/4" holes in the cork. Put a short 12" tube through the cork an inch into the bottle and a 3' tube through and all the way to the bottom of the bottle.

Stick the cork back into the bottle.

Stretch (enlarge) the end of the long tube with a needle nose pliers and stick it over the bleeder. You ready to bleed.

I also use this as a power bleeder for brakes. I clean the bottle and put the fresh brake fluid in the bottle. Have a plate with rubber seal sheet and fitting I can clamp on the brake master and attach the long hose to. Then charge the bottle with the caned air. Open the caliper bleeders and away you go!

I now have the most peddle I have had since I got the car running three months ago.

Now can hold the peddle down for as long as I want and it stays. Have over 1" of slave travel. Shifts have never been so good!

[This message has been edited by Dodgerunner (edited 05-15-2007).]