| | | quote | Originally posted by timgray:

Anyone have any info on air-Water intercoolers?

Would this be a way to put a intercooler in a hot place (engine compartment with no air flow) and then run a pump and water lines to a radiator in front of the car and get the same effect? I am looking at options to get decent air charge cooling (Drop it to at least 160 degrees) without having to route big 3.5" air lines all over the place. Installing a pump and smaller water lines are far easier to do. |

|

I came across this article recently:

http://www.mr2supercharger....tercoolingPage1.html Page 5 also has a bit of discussion specific to W2A IC's. The same author has an interesting piece about intercooler math on AutoSpeed:

http://autospeed.com/cms/A_109789/article.html (If you haven't seen it, AutoSpeed is an Aussie automotive e-magazine. A number if interesting articles in the DIY and Tech archives).

The one thing that really caught my eye was the statement that a turbo car is only on boost about 5% of the time, and that full boost situations rarely last more than 15 seconds (well, except maybe climbing up the passes in the continental divide). I had a Chrysler Daytona 2.2 turbo from '84 through '92, from what I recall, the 5% on boost figure is about right, no boost when cruising around at a steady speed, just on acceleration/hill climbing. The interesting thing about this 5% "boost duty cycle" is that the 95% of the time the turbo is not adding heat to the IC would allow more than sufficient time for the radiator to bring the water temp back down between bursts of boost.

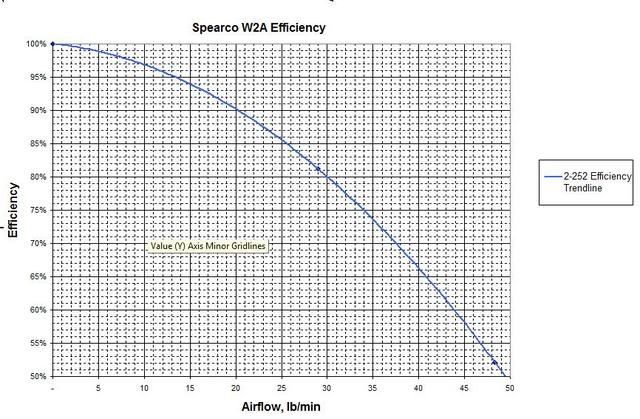

After a bit of searching I came across this info on Spearco W2A intercoolers:

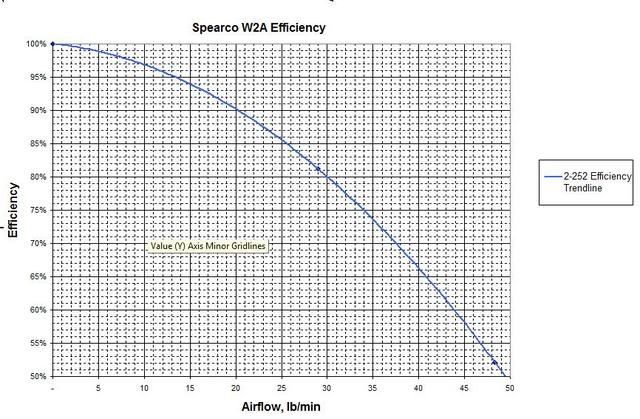

http://www.racetep.com/tneticatolic.html . The 2-252 unit is the smallest W2A unit shown, and has a data sheet showing charge cooling results for 275* inlet air at 15 PSI boost and two different airflow rates. A little bit of math shows that the IC efficiency using 110* water is 81% at 270 CFM and 52% at 450 CFM. Since a Gen 1 3.2 is not going to pull anywhere near 450 CFM, this is probably a good size intercooler for that application.

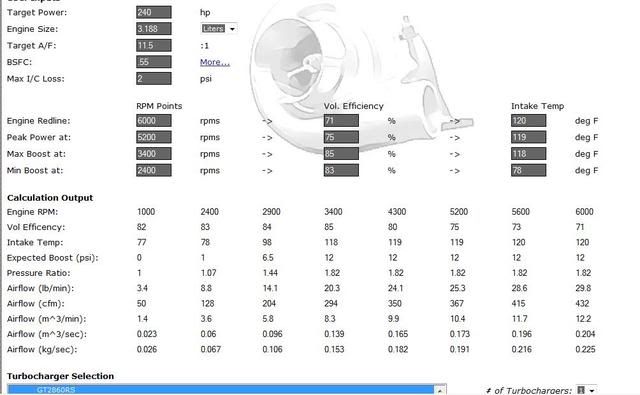

** Disclaimer - what follows is just playing with math, doing a bit of bench racing**

I wanted to see what the efficiency curve of this IC was, and get an idea of the impact to power generation on a gen 1 3.2. The first step was to convert the IC airflow data from CFM to lb/min. Made the assumption that the lower the mass flow, the closer to the water temperature the air would be. In theory then, at 0 lb/min the air in the IC is the same temperature as the water. I called this 100% efficiency (even though the IC is probably acting as an interwarmer at that point) for purposes of generating a trendline. Anyway, here's the graph:

Key assumption for what follows is that the trendline generated above is applicable to different air temp and pressure values - the efficiency is dependent only on mass air flow through the IC.

Other key assumptions are:

- each pound of airflow generates between 9 and 10 HP at the crank (used ~9.4 here)

- that airflow is dependent on VE regardless of boost level. Pushing air instead of sucking it doesn't increase the ability of the engine to flow CFM

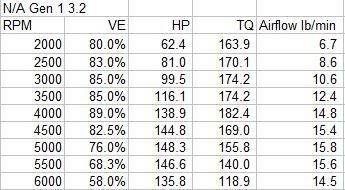

I used the following VE values for all scenarios:

RPM - - --VE

2000 - - - .8

2500 - - - .83

3000 - - - .85

3500 - - - .85

4000 - - - .89

4500 - - - .825

5000 - - - .76

5500 - - - .683

6000 - - - .58

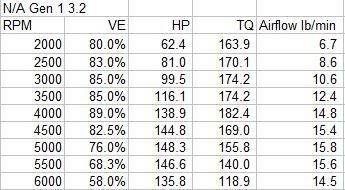

SANITY CHECK: A stock 3.1 generates 180 ft-lb of torque and 140 HP, so with a bit of gasket matching, port clean-up and exhaust manifold work, 150 is easily reached in a N/A engine. Using the VE and HP per pound of airflow above, you get the following:

The assumptions result in power and torque numbers that are comparable to stock, the shape of the torque and HP curves may be off a bit, but good enough.

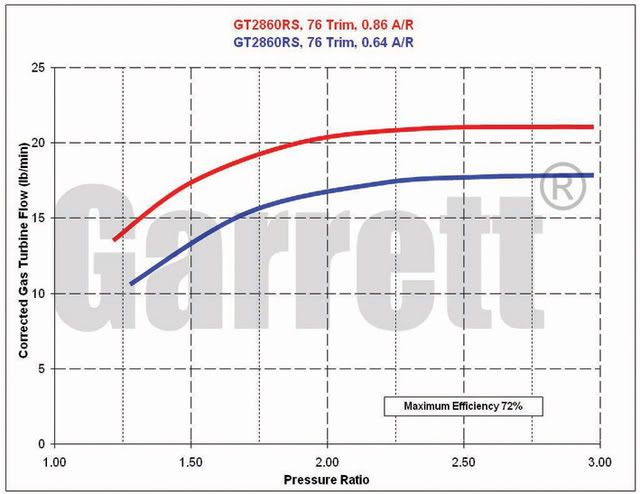

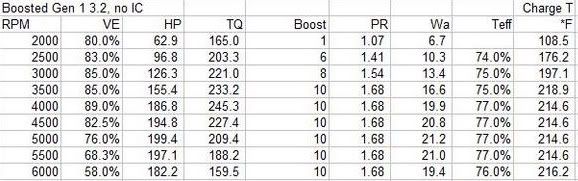

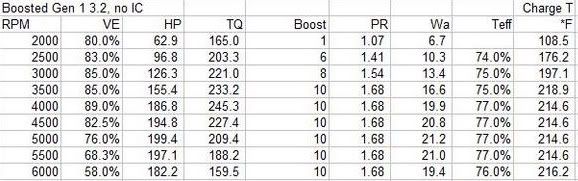

So if you apply 10 pounds of boost to this theoretical engine, this is what things look like:

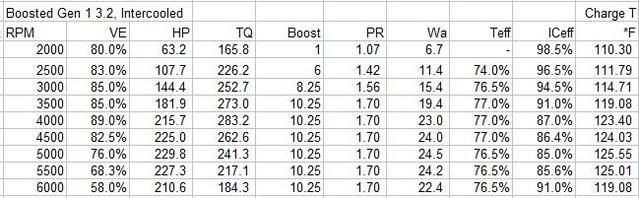

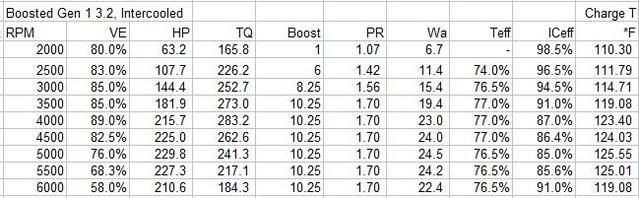

If the IC efficiency curve above has any bearing on reality (I think the curve shows too much efficiency) then using this intercooler results in :

This looks like about 90* reduction in charge temperature and 25-30 more HP and Torque as compared to no intercooler.

Based on the prices on the Top End Performance website, you're probably looking at $1,300 or more to build an IC set-up with all plumbing (using new parts). Seems a bit steep, but then again, it might just keep detonation at bay and save the engine.

Cheers