|

|

|

|

3.1 TGP ENGINE SWAP INTO FORMULA by Scoobysruvenge

| Started on | : 04-14-2009 02:44 PM |

| Replies | : 292 |

| Last post by | : Scoobysruvenge on 07-17-2009 11:56 AM |

|

|

|

|

Jun 17th, 2009

|

carbon

Member Posts: 4767

From: Eagan, MN

Registered: Apr 2004

|

So on a Gen II or III aluminum head it would be the side with the spark plug... being a heart shaped chamber...

IP: Logged

|

12:46 PM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

Carbon,

That’s how I interpret this information as well, the heart shaped chamber makes it an asymmetrical combustion chamber and the spark plug is offset to the exhaust side of the head. So I should be good with the spray bars mounted to the outsides of the windage tray like I have now.

If someone sees a problem here let me know what you think.

Thanks for looking

IP: Logged

|

01:07 PM

|

|

|

Jun 19th, 2009

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

I found a Ferrari 308 body kit for sale, it seems to be complete including tails lights and bumpers , it has been taken out of the package but never monted to a car . What is fair market value on a kit like this????? I cant find any manufacture name but the glass is quite thick and does not feel fleemsy.

IP: Logged

|

02:17 PM

|

|

|

Jun 25th, 2009

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

I haven’t had a lot of time for my project lately, even so I find a moment here or there in my busy day for all things Fiero and yesterday I had one of those moments. While replacing the engine in my fathers 2007 Jetta turbo diesel engine that took a dump after only 123,000 miles (German engineering my a$#) I was removing some parts of the old block when I noticed some piston oil squirt nozzles and was immediately mesmerized by the prospect of examining first hand a factory oiling system. The nozzles were not easy to remove as the block was well ventilated as you can see in the pics below.     Mind you now my father is 80 and the cars oil change and maintenance schedule have been followed to the letter. Getting back to the oil squirt nozzle thing, I found that two of the nozzles were undamaged and removed them and found they did indeed have check valves in the connector bolt.  Even more surprising was the size of the throat on the nozzle and the shape of the tube. The tube its self was simply a swaged at the end with no orifice or special shape and the when I measured the opening it was 65 thousandths!!!!!  I’m thinking that I will increase my spray bar hole size to 40 or 45 thousandths. This will eliminate the whole broken drill bit problem. I hope to get back to my project this weekend. To get all there is out of living, we must employ our time wisely, never being in too much of a hurry to stop and sip life. Robert Updegraff

IP: Logged

|

09:22 AM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

| | | quote | Originally posted by Scoobysruvenge:

I found a Ferrari 308 body kit for sale, it seems to be complete including tails lights and bumpers , it has been taken out of the package but never monted to a car . What is fair market value on a kit like this????? I cant find any manufacture name but the glass is quite thick and does not feel fleemsy. |

|

Bump he wants 2500 $

IP: Logged

|

11:36 AM

|

|

|

Jun 26th, 2009

|

Will

Member Posts: 14268

From: Where you least expect me

Registered: Jun 2000

|

| | | quote |

To get all there is out of living, we must employ our time wisely, never being in too much of a hurry to stop and sip life.

Robert Updegraff |

|

You like Reagan? "Government's view of the economy could be summed up in a few shortphrases: If it moves, tax it. If it keeps moving, regulate it. And if it stops moving, subsidize it." --Ronald Reagan

IP: Logged

|

08:25 PM

|

|

Will

Member Posts: 14268

From: Where you least expect me

Registered: Jun 2000

|

| | | quote | Originally posted by Scoobysruvenge:

[QUOTE]Originally posted by Scoobysruvenge:

I found a Ferrari 308 body kit for sale, it seems to be complete including tails lights and bumpers , it has been taken out of the package but never monted to a car . What is fair market value on a kit like this????? I cant find any manufacture name but the glass is quite thick and does not feel fleemsy. |

|

Bump he wants 2500 $ [/QUOTE] There's no such thing as a bolt-on body kit. You could be looking at as much as a couple of hundred hours of bodywork to get the kit on the car and ready for paint.

IP: Logged

|

11:54 PM

|

|

|

Jun 29th, 2009

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

I got to work this week end and started fabricating the oil pressure test rig ….. I started with the pressure chamber using a short piece of 2 inch tubing and sealing one end by welding a flat plate to the bottom of it.  I then drilled a hole in the center of the plate and welded a threaded nipple over the hole. An air chuck was then screwed on the nipple.  With the air end of the chamber complete it was time to get the other end ready.  I welded a plate on the other end of the chamber, drilled a hole in the center and welded a coupling over the hole.  I plugged the oil end of the chamber hooked up the regulator and pressure tested it at full shop air pressure and found no leaks.  I then screwed a brass brake line fitting to accept the test line I fabed up earlier in this thread and attached the line from one of my spray bars.  A quick fill of the chamber with 10W 30, a big zip tie to hold the chamber on the engine stand, a bend here or there in the tubing, a couple of vise grips to hold the bar to the windage tray was ready for some air.  I rolled over the shop cart and hung the regulator where it would be easy to read and got ready for a room temperature test of the spray.  My first test rund I applied 25 pounds and gradually raised it to 60 pounds observing the spray on the 1, 3, and 5 cylinders.  Earlier in the thread I was looking at my Pop’s VW spray set up, the jets were around 65 thousandths, this got me thinking, so I left the #1 spray hole at 28 thousandths, upped the size of the #3 hole to 40 thousandths and the #5 hole to 60 thousandths for my test. The results are as follows….. First the .028 hole sprayed extremely well up to about 35#s and then began to break up before it got to the piston crown above 35#s. Next the .040 hole performed well up to almost 60#s but below 30#s there was an arch in the stream indicating an inadequate flow pressure. Finally the .060 hole had a large arch most of the way up to 60#s of pressure, at 60#s there was still a slight arch in the spray. After this initial test I can see the need for a check valve and I’m sure it will need to be at least 25#s before it allows the oil to spray due to the lack of oil flow below this pressure. This mentality may change if the velocity increases on the hot oil test. I then refilled the chamber with oil and began a slow heating with a torch to bring the oil up to 190 degrees for a hot oil test but almost immediately the oil began to bubble out of the fill. My next thought was to heat the oil in a separate container and then pour it into the container for the test, but I was out of time. I considered using substitute liquid like antifreeze to simulate the hot oil what do you guys think?????????????? Thanks for looking.

IP: Logged

|

10:41 AM

|

|

Joseph Upson

Member Posts: 4951

From:

Registered: Jan 2002

|

The test needs to be conducted with the jets in the proper position facing upward so that you can see the effect gravity will have when the engine is up right.

IP: Logged

|

01:57 PM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

Joe,

I plan on a right side up test once I have the nozzle size close and working somewhere around normal operating temps.

I am unsure how the thinner oil will react through the nozzles, but I expect to pick up some velocity with the thinner oil, but this is purely speculation. I would have said that at .060 the cold oil would have been rolling out in a nice steady stream (boy was I surprised)

Thanks for your interest.

IP: Logged

|

02:14 PM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

Will,

When Regan was elected I was 11 years old and when his last year in office came around it was my first year of university.

The 308 kit is a sweet looking thing, I am a ways from doing something with the body but if I can swing the 308 kit it can collect dust until I am ready to install it as it is as close to a Ferrari as I will probably get in my lifetime, so damn the time consuming part I’ll cross that bridge when I get there.

I see you are making some progress with your Caddy swap, I’m looking forward to seeing it completed. Good luck and god’s speed.

Thanks for looking.

IP: Logged

|

03:15 PM

|

|

|

PFF

System Bot

|

|

carbon

Member Posts: 4767

From: Eagan, MN

Registered: Apr 2004

|

| | | quote | Originally posted by Will:

You like Reagan?

"Government's view of the economy could be summed up in a few shortphrases: If it moves, tax it. If it keeps moving, regulate it. And if it stops moving, subsidize it." --Ronald Reagan |

|

Yeah... that was why I liked him... that was his argument for a smaller federal government... you should read more or not quote out of context. That was why he tried to lower taxes, deregulate industry and reduce subsidies... and I was only 2 when he was elected  | | | quote | Originally posted by Scoobysruvenge

The 308 kit is a sweet looking thing, I am a ways from doing something with the body but if I can swing the 308 kit it can collect dust until I am ready to install it as it is as close to a Ferrari as I will probably get in my lifetime, so damn the time consuming part I’ll cross that bridge when I get there. |

|

So did you buy it? [This message has been edited by carbon (edited 06-29-2009).]

IP: Logged

|

08:12 PM

|

|

|

Jun 30th, 2009

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

I prefer the Slick Willey take...

The new rage is to say that the government is the cause of all our problems, and if only we had no government, we'd have no problems. I can tell you, that contradicts evidence, history, and common sense.

William J. Clinton

IP: Logged

|

07:51 AM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

I am waiting for a manufacturer name and some logistical details before I jump.

IP: Logged

|

08:21 AM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

When I set out to do a piston oil squirt set up I thought it would be a strait forward modification, but the further I get into this thing I am realizing that I am going to have invest a lot more time in R&D than I initially planned on to get it right.

I am now wondering if each of the holes will need to be different sizes to compensate for the loss of pressure as the number jets passed increase before the oil reaches the end of the bar???

(This will take some trail and error to figure out)

There is about 4 inches between the nozzles and the piston crown, how much will windage affect the stream of oil as it travels through the crankcase to reach the crown of the piston???

(I see a lot of patent material on spray bars and they are mounted to windage trays or the main cap bolts so I assume it will be OK)

What oil should I be running for my engine application??? and shouldn’t I be using this oil for my tests???

(I haven’t even researched this yet)

“And this was on my mind”

Patton

IP: Logged

|

09:34 AM

|

|

|

Jul 1st, 2009

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

Finding the viscosity of oil and antifreeze has been a challenge as it is measures several different ways and can include pressure as part of the equation. This is a simple break down I found after some research, although the 10 and 20W oils are not rated at 210 degrees it allows me to see that antifreeze will not work as a substitute.

Specific Gravity and Viscosity of Liquids

Liquid Boiling

point

at

atm

press Specific gravity Viscosity

Temp Based

on water

= 1 at 60ºF Temp centistokes SSU

ºF ºC ºF ºC

Automatic

crankcase oils SAE 10W

SAE 10W

SAE 20W

SAE 20

SAE 30

SAE 40

SAE 50 60 15.6 .88-.94 0 -17.8 1295-max 6M-max

60 15.6 .88-.94 0 -17.8 1295-2590 6M-12M

60 15.6 .88-.94 0 -17.8 2590-10350 12M-48M

60 15.6 .88-.94 210 98.9 5.7-9.6 45-58

60 15.6 .88-.94 210 98.9 9.6-12.9 58-70

60 15.6 .88-.94 210 98.9 12.9-16.8 70-85

60 15.6 .88-.94 210 98.9 16.8-22.7 85-110

Ethylene glycol 60 15.6 1.125 70 21.1 17.8 88.4

Water, distilled 60 15.6 1.00 68 20 1.0038 31

Water, fresh 60 15.6 1.0 60

130 15.6

54.4 1.13

0.55 31.5

The antifreeze is 17.8 centistokes at 210 degrees, if we compare this to the maximum viscosity for the SAE 40 we find 16.8 centistokes. I’m sure that SAE 40 is going to be thicker than any thing I will run in my engine.

What type of oil are you turbo 60D guys using ???

The search for a suitable test liquid that I do not have to heat continues.

Thanks for looking.

IP: Logged

|

08:53 AM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

Finding the viscosity of oil and antifreeze has been a challenge as it is measures several different ways and can include pressure as part of the equation. This is a simple break down I found after some research, although the 10 and 20W oils are not rated at 210 degrees it allows me to see that antifreeze will not work as a substitute.  The antifreeze is 17.8 centistokes at 210 degrees, if we compare this to the maximum viscosity for the SAE 40 we find 16.8 centistokes. I’m sure that SAE 40 is going to be thicker than any thing I will run in my engine. What type of oil are you turbo 60D guys using ??? The search for a suitable test liquid that I do not have to heat continues. Thanks for looking.

IP: Logged

|

08:56 AM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

As I was looking through the tables I found a listing for Glycerin and Glycerin with 50% water. This got me thinking that if I add water to the antifreeze as a percentage I can arrive at the simulated viscosity of the oil I will use at 210 F.

What oil should I be using in the 60D turbo engine ????

IP: Logged

|

09:36 AM

|

|

|

Jul 2nd, 2009

|

sardonyx247

Member Posts: 5032

From: Nevada, USA

Registered: Jun 2003

|

| | | quote | Originally posted by Scoobysruvenge:

As I was looking through the tables I found a listing for Glycerin and Glycerin with 50% water. This got me thinking that if I add water to the antifreeze as a percentage I can arrive at the simulated viscosity of the oil I will use at 210 F.

What oil should I be using in the 60D turbo engine ???? |

|

I run Mobile 1 or Valveoline full synthetic oil and I look for a 20-50 or a 5-50, but I also live in Vegas were it is HOT, 120+ degs HOT Remember to run cheap oil for the break in. IE: NOT synthetic Oh and NEVER run penzoil or quaker state oil, both are waxed based and CAUSE sludge, or royal purple it wears your engine. ------------------

"DRIVE IT LIKE A FIERO"

'84 Fiero, engine to be determined

'87Blue GT 3.4L Swap Completed!!!!!!!! Boosted!!!!!!!

^^^^ Now in the Construction Zone^^^^

Las Vegas Fiero Club

Fiero Road Club Of Northern Nevada

IP: Logged

|

07:06 AM

|

|

|

Jul 6th, 2009

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

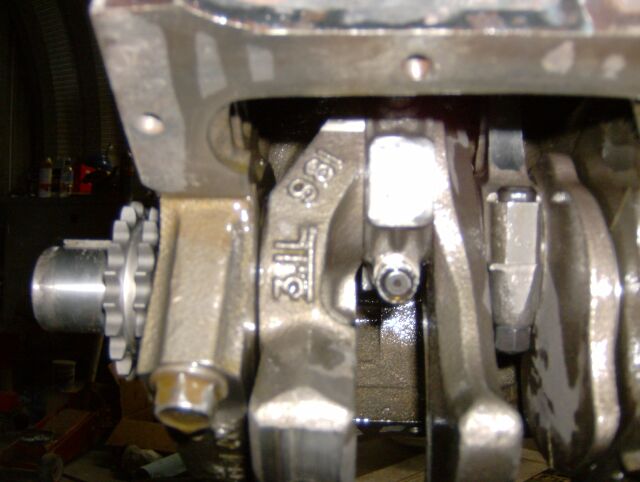

I got some time over the holiday to work on the spray bar set up…… The chamber I fabbed up ran out of fluid to fast so I cut the chamber to allow for some more volume.  I found another piece of scrap to weld in the middle.  Set it up in the vice to ease the job.  With more volume added to the chamber I was ready to do some testing.  I mixed up an antifreeze/water solution at 50/50, put some 20/50 oil on the Bunson burner and heated it to roughly 210 degrees. The hot oil was placed in an olive oil cap that had a .028 hole in it, I then timed the drain 23 seconds. The antifreeze was next on the time table and came in at 27 seconds. I mixed a new batch of antifreeze at 60/40 and timed it at 22 seconds (close enough) I played around with the jet sizes and pressures half the morning, I used #70 .028, #65 .035 and #60 .040 bits and pressures from 25 – 60 pounds of oil pressure.  I used vice grips to adjust the roll on the bar so it would hit the piston crown just right. When set at the correct angle and jetted I will simply tack it into place.  I settled on the #65 .035 bit as it performed the best at all pressures, however there was an anomaly that plagued me no matter what jet size I used. The first jet would not stream like the 2 jets beyond it.  What I found out was that the feed line from the chamber attached to the bar were different sizes and creating turbulence where the first jet was located. I added a three inch nipple to the bar for testing and the problem disappeared (staggered jet sizes would not be needed) Settling on the #65 .035 jet size I tacked the 1st bat to the tray after it was rolled into place.  I then drilled the 2nd bar at .035 rolled, tested and tacked it into place. With both bars fastened to the tray it was time to tackle the crossover tube.  The crossover tube was fish mouthed at both ends, holes were drilled in both bars to accept the crossover tube and the tube was tacked into place.  A final weld put on the outer face of the crossover stitched in slowly as not to cause warping that might alter the trajectory of the jets.  Holes were made with a drill and dremmel on the inside of the tray to weld the back side of the crossover tube for a complete seal.  With the crossover tube mounted it was time to set up the feed from the oil pan. I will use hard brake line most of the way and run only enough braided line so that the pan can be removed enough to connect it due to the harsh environment it will be operating in.  In order to feed the crossover tube another hole needed to be drilled on the under side of the bar and a coupling welded to accept a fitting, the tray also need a large hole drilled so the brake line fitting could be screwed into the coupling welded to the crossover.   With this complete a piece of brake line and a brass fitting were attached to the pan to ensure a good fit.  I will have more pics and info soon. Thanks for looking.

IP: Logged

|

10:10 AM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

Now that the spray bar is almost complete, I decided to clean the water out of the block. I removed the crank, rods and pistons from the block and removed any traces of water, I then oiled all the parts to ensure no rust would form.  While cleaning every thing I found something that disturbed me, take a look and see what you think….  It appears that one of the rods is bent, I may find this is not the case after I measure them, but it sure looks bent to me. Here is another take.  I figure if it is bent, the engine may have had a blown head gasket a some time, compressed some water and bent the rod ??? I have read that small Chevy rods can be used… Has any one used these rods or have any information on the swap??? I am figuring that they at the very least will need to be narrowed to fit on the crank, but this is pure speculation. I will let you guys know what I find when I measure the dwell on the pistons to see if they are bent.

IP: Logged

|

11:37 AM

|

|

|

PFF

System Bot

|

|

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

Fitting spray bar in the test oil pan revealed a tight fit in one spot.  A slight adjustment with a precision tool to the TGP oil pan took care of this issue.   The pan tray needed modification to fit the crossover tube, instead of cutting and jerry rigging it back together so I removed the entire insert and will customize the pan with all new baffles and a trap door (another mini project)  “The saga continues” Wu-Tang Clan

IP: Logged

|

01:11 PM

|

|

|

Jul 7th, 2009

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

The possibility of one of “me precious” factory TGP rods being bent was burning my a$$, so I took a little time I didn’t have yesterday to investigate it… I selected two rods, the suspect #2 rod and the excellent looking #6 rod. The #2 is shown below.  I oiled the bearings and the piston and used some rubbies on the rod bolts for installation purposes on the good #6 rod.  Placed it in the bore and snugged the cap and nuts.  The dwell plate was then installed on the engine block.  Some locating marks were placed on the crank and block to help with the TDC measurement.  With the piston at TDC the dwell plate was adjusted and locked in place.  The crank was then rotated several times to ensure that all was well with the dwell setting.  I then oiled the bearings and the piston on the suspect #2 rod, slid it in the bore and tightened the cap and nuts.  I rotated the crank but made no contact with the dwell, it was obvious that the piston wasn’t even close and no dial indicator would be needed to measure the difference, instead I used a feeler gauge and found slightly over 20 thousandths of a gap.  I will have to look into the small Chevy rod swap, I did some research on this subject and I will post what I have and what I find soon.

IP: Logged

|

09:15 AM

|

|

Joseph Upson

Member Posts: 4951

From:

Registered: Jan 2002

|

You should check them all before jumping to conclusions. I'm sure there is some influence involving casting mold differences in the pistons that could account for some of that on an older production motor, especially considering the +/- attributed to piston and rod weights. My engine has an advertised 5.9" connecting rod length but it is actually 5.827" and a 5.9" rod has been confirmed for another engine like it. Imagine what kind of problems that could present if both my engines have a version of each rod and I at some point decided to mix and match before finding that out.

IP: Logged

|

10:48 AM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

On this episode of Myth Busters we’ll be looking at the small Chevy v8 rod swap into a 60 degree v6 engine, this swap in mentioned in many circles like the 60D forum and Pennocks Fiero. We will through hard facts prove or debunk this myth. I started by trying to verify the main journal sizes of the 60D engine, specifically the 981 crank casting used in the TGP block. Summit racing gave me these numbers for a AWD 3.4 van main journal(all 981 cranks are cast for AWD vans) 2.1265 to 2.1275 60DegreeV6.Com lists the following specs… 3400 2.6473 to 2.6483 3100 2.6473 to 2.6483 3.1 Gen2 2.6473 to 2.6483 The Turbo Grand Prix spec sheet lists the big end of the rod http://www.turbograndprix.c...nd%20Differences.htm3.1 TGP 2.474 As you can see the hard numbers are pretty soft, now small Chevy rods come in three basic sizes. 2.000 2.100 2.240 None which match the information above, so I decided to measure my journal to get an exact number.  I came up with 2 inches exactly… This was good as 5.7 rods with a 2 inch journal are cheap and there is a wide selection available good to 600 HP for 300 $ or less. (Scat, Eagle ECT…)  These rods have a small end pin hole size of .927 and the 60D TGP rod small end is .905 these can be bushed to .905 or if custom pistons are used they can be ordered with full floating pins at .927 So far things were looking good for the small Chevy rod swap, so I measured the big end width.  I came up with .848, the small Chevy rods are .947 This did not surprise me, as I expected the small Chevy rods to be wider. Armed with my new found info I called Lewis at The Shop (my local machinist) And inquired about what would be the best way to machine these rods. He informed me that the small Chevy rods have a slight offset, but there should be enough material on the rod to machine the offset out and end up with what I want. More measurements will be needed but this swap seems viable so far. I hope to do the machine work here in the shop but if it seems to complicated I will farm it out to Lewis, he gave me a ball park price of 30 $ a rod (180 $) I will post more as I get the information. Thanks for looking

IP: Logged

|

11:17 AM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

Joe,

I have already checked all the crank journals and they check out OK, I was playing on borrowed time last night and just did not have enough time to check them all, but be sure before I spend any hard earned scratch on new rods I will check them all with a dial indicator. I hope to get to this tonight, but I am 99% sure the rod is bent.

Thanks for your input.

IP: Logged

|

11:25 AM

|

|

sardonyx247

Member Posts: 5032

From: Nevada, USA

Registered: Jun 2003

|

I looked into this too, but the machine shop said that the 3.4 rods I have are basicly like SBC rods, as in thickness and strength.

and they are a huge differance in size than the 2.8L rods. I don't know where the 3.1 falls into what catagory.

IP: Logged

|

04:07 PM

|

|

|

Jul 8th, 2009

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

Don,

I’m not sure about the 3.4 rod or any other 60D engine other than my own after looking at the information on line, some of which have been quoted here in this thread as it makes no sense, I suspect all 3.1 and 3.4 blocks have a 2 inch or 2.1 journal on the crank.

Having a small journal on the crank is not necessarily a bad thing, it allows for a higher overall RPM in the engine, so I’m glad it is the 2 inch journal as this makes finding replacement rods much easier .

I spoke with another machine shop yesterday (Ballos Precision Machine) about machining the rods, he said he was familiar with narrowing small Chevy rods for other applications and quoted me a price of 75$ to machine all 6 rods!!!

Being suspicious I asked about the offset in the small Chevy rods and how the bearing tangs lined up, he said that the bearing tangs were opposite of the of the offset side of the rod and would not need any modification as it was the offset side of the rod that would be machined to narrow it.

I wanted to use the factory TGP rods, but since I can’t I’ve been looking around at rods and let me tell you the SBC rod market is ridiculously cheap!!!

Depending on whose product you choose will dictate on how much quality you will receive.

Ordering a set of 8 allows me the luxury of selecting the best 6 of 8 or removing the bottom 25% and having two spares. I’m pretty excited at getting some whip a$$ rods for my engine for 450$ or less, including the machine work.

Now if you figure the cost of the resizing of the rods at the machine shop that I’m not going to spend were looking at around 350$.

I am worried about having to add expensive Mallory metal to the crank in order to balance it with what I suspect will be a heavier set of rods. I am currently leaning toward using I shaped rods as they are much lighter.

Something that bothers me is why I do not see any damage to anything other than the rod, no piston damage or bearing wear???

I can come with a lot of scenarios of how this could be…

The rod was simply out of spec and they slapped it in there… I find this unlikely looking at all the little extras done to this engine.

The car blew a head gasket at some time, sat in some yard until it went to the bone yard where they started it for a test but did not let it run long enough for it to warm up and raise hell… I find this is plausible.

The junk yard was a ripoff… I find this probable.

Whatever the reason I will not let it impede my progress.

IP: Logged

|

09:57 AM

|

|

sardonyx247

Member Posts: 5032

From: Nevada, USA

Registered: Jun 2003

|

|

sardonyx247

Member Posts: 5032

From: Nevada, USA

Registered: Jun 2003

|

|

|

Jul 9th, 2009

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

What do you guys know about aluminum rods on a street motor????

IP: Logged

|

09:27 AM

|

|

|

PFF

System Bot

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

I have the opportunity to purchase some aluminum rods at a great price and I think I’m going to buy them today.

I will probably regret this but I feel I have done the research needed to ease my mind on using these for a street engine.

Aluminum rods have gotten a bad rap over the years in many circles, but this stigma seems to be unwarranted after speaking with some people who sell the rods and some who don’t.

Aluminum rods stretch after a few thousand miles.

This may have been true in the early 70’s but is no longer as issue unless you are driving a 1000 hp race car. BME claims 200,000 miles in a street engine turning below 8,000 RPM (that’s impressive!)

Aluminum rods shrink and expand too much.

We have been using aluminum heads and blocks for years without common failure.

Aluminum rods wear out the bearings in the engine prematurely.

True that different clearances will be needed to use the rods, but there are many users on line with 800 HP engines with 50 or more passes on the dyno without ill effect.

The rods that I’m looking at are rated at 800 HP and 10,000 RPM

If some of you can bring me back from this madness before I spend my money, let me know what you know.

IP: Logged

|

12:45 PM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

Check it out!!!!

IP: Logged

|

12:50 PM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

Thanks for the pics and info, and sorry about the Mobster Don Fiero thing...

IP: Logged

|

02:28 PM

|

|

sardonyx247

Member Posts: 5032

From: Nevada, USA

Registered: Jun 2003

|

| | | quote | Originally posted by Scoobysruvenge:

Thanks for the pics and info, and sorry about the Mobster Don Fiero thing... |

|

oh I thought you got the don from sar'don'yx, your fine then, you can call me Don, lmao  I wanted new rods but between cost and looking at how much bigger the 3.4l rods are, I just polished mine to releive stress risers. As far as aluminum rods, I never looked into the differances. you don't want them to stretch, (if they do idk) as that would raise compression, bad with boost. Something to look into first. Or look at Summits website and see what they offer in the size you need for other types of rods.

IP: Logged

|

04:05 PM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

I had to share this Ebay deal I just stole.

IP: Logged

|

04:18 PM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

These are new, never used by the way!!!!

IP: Logged

|

04:20 PM

|

|

Will

Member Posts: 14268

From: Where you least expect me

Registered: Jun 2000

|

|

|

Jul 10th, 2009

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

When I started this project my goal was to use as many stock parts as I could to reduce cost and allow the project to move forward at a good pace.

One of the low points of this build so far came when I found out I had a bent connecting rod cleaning the components up after testing the piston oil spay system. I now needed a set of rods for my engine with no aftermarket available for the little 60D.

I didn’t want to go backwards replacing my TGP 1037 heat treated rods with quenched caps for a set of stockers, so I decided to try and unravel the small Chevy rod swap mystery. After some research backed up with hard facts I had come to the conclusion that this swap seemed possible and cheap, now I had to select a set of rods.

I looked extensively at Ebay and known rod suppliers and found a lot of bang for my buck. I was looking at the SCAT rods which seem to be a little better than the Eagle rods, the SCAT rods are Chinese forgings, but they are machined in America unlike the Chinese machined Eagle product

Then all thoughts of the old and faithful steel rods went to hell when a set of sexy aluminum rods laid down in front of me and refused move (Mmmm... Exotic)

I knew instantly that they would be high maintenance, but there was nothing I could do. I was caught in their gaze and could not escape.

I watched Ebay all day knowing some Jonny come lately would come along, flash some major chips and off into the sunset they would go hand in hand. To my amazement they went home with me with only a light hearted attempt from the competition to steal them away, at the end of the day they were mine.

I was now married to these pieces of forged aluminum for better or worse.

Now that I have procured these aluminum rods, I am slowly coming down of the high of part lust, and coming back to my senses and realizing I am in uncharted waters without a navigator wish me luck.

IP: Logged

|

10:10 AM

|

|

Scoobysruvenge

Member Posts: 550

From: Richmond Virginia

Registered: Apr 2009

|

The small Chevy con rod big end width is .940 and the 60D con rod big end width is .848 leaving .092 thousandths or roughly 3/32 this isn’t much at all, with the rods rated for 800 hp and 10,000 RPMs should surely hold up to my 350 HP goal with room to spare.

If it turns out something is wrong or I can’t use them I can always sell them, I’m sure I can get my 92$ back out of them.

Thanks for looking.

IP: Logged

|

10:32 AM

|

|