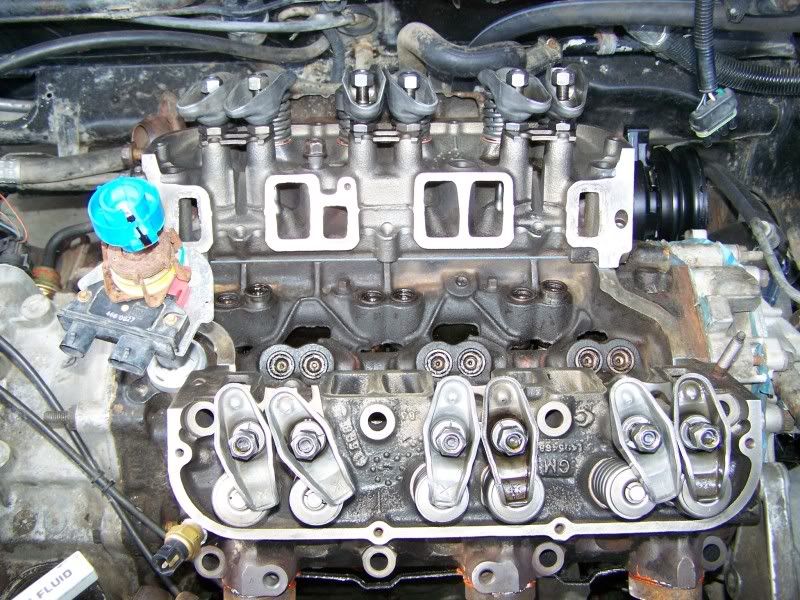

How I've adjusted my valves: 2.8 engine V-6

The idea is to get the lifter poppet part way down into its bore, about 1/4-1/2 of its travel. If you don't use up some of its travel, then your valve(s) will get loose as normal wear on valve-train parts causes the poppet to reach the top of it's travel. It will also requires more oil to remain (at pressure) in the lifter's plunger cylinder. The more volume to fill, the more chance that the plunger can be compressed, causing a ticking noise or at high revs a bent pushrod.

Make sure that the lifter being adjusted is on the base circle of the cam, this will be TDC on that piston with both valves closed. TDC #1 is where both #1 valves are closed and main fat timing mark on harmonic balancer is at zero on timing tab and distributor rotor is pointing at the number one plug wire terminal. Set your intake and exhaust valve lash on #1. Rotate the harmonic balancer clockwise 120* to the next timing mark and you know that you are at #2 TDC. Set your intake and exhaust valve lash on #2. The next timing mark after that is #3 TDC and so forth. Remember that the GM/Fiero engines have three timing marks (0*, 120* and 240*) on the harmonic balancer, which makes this much easier than the Chiltons manual method.

The lifter plunger centering adjustment is 1&1/2 turns. Most people think is too much. It is not. The 1&1/2 turns (as specified in the FSM) will center the lifter plunger on an OEM valve train (with the standard rocker ratio). The reason most think that 1&1/2 turns is too much is because they don't properly identify the zero lash point. If you are twirling the pushrod you won't be able feel the zero lash point unless your hands are 500 times (give or take) more sensitive than the average human. Anyway, while approaching the zero lash point, you should be gently rocking the pushrod up & down between the lifter and the rocker arm. That way you can feel the play diminish down to zero.

Wiggle the pushrod back and forth as you tighten the rocker nut, you will feel the pushrod end "clicking" as it moves around. The amount of movement will decrease as the nut is tightened until suddenly it stops. This is the point where the lash is out with the poppet at the top of it's bore. Now, you need to move the poppet down its bore, so you continue to tighten the rocker nut.

How much you ask? Well, the rocker stud has a 1.5mm pitch, so one full turn moves the rocker ball down 1.5mm. The rocker arm ratio (stock) is 1.5:1, so moving the rocker ball down 1.5mm moves the pushrod down 1.67x1.5mm, or 2.5mm plus or minus a very tiny bit. The lifter poppet travel is 6-8mm, so 1.5 turns on the rocker nut (factory spec) is 3.8mm at the lifter poppet, or about half-way. That's how much I tightened mine, and it worked just fine. Any less and the valves will need readjustment sooner due to wear.

I had mechanics using the Chiltons manual mess up the lash, I tried the twirl and turn method and it was noisy as marbles. Jazzman gave me the pitch and rocker ratio measurements above and I went with timing marks on the balancer and the 1-1/2 turns on rocker arms. My engine is smooth now. Lots of power. Most important to me is that I wont have to go through the work to tear the upper half of the engine out to get the lash adjusted for a very long time. Some people have had success with other methods, all the power to you. If there is an easier way, count me in! Good luck with setting your lash and I hope you are using the rubber valve cover gaskets, they are sweet and don't leak.

------------------

jetman

Silver 86 SE 2M6 4-speed, with "check wallet light"

Now fortified with 8 essential slices of bacon goodness

I have a small shoplight and a headlight so I think I'll be fine.

I have a small shoplight and a headlight so I think I'll be fine.