here is that link for the gm race engine. 1650 horsepower

http://www.gm.com/company/r...ogy/MattHartford.htmThis is one bad ass engine

When GM Racing entered the NHRA Summit Racing Sport Compact series in 2002, it did so with the primary goal of capitalizing on the extremely stressful demands of side-by-side quarter-mile competition to test the thresholds of production-based components.

The Summit Sport Compact series, like other venues in which GM Racing competes, has allowed engineers to take lessons learned from the racetrack and transfer that technology to the benefit of the consumer.

In less than three years, GM Racing and GM Powertrain engineers have worked together to achieve extraordinary levels of reliability, durability and performance numbers just short of 1100 horsepower with the turbocharged Ecotec 2.0L engine, the same four-cylinder championship powerplant used in the Pro FWD Chevy Cavalier of Nelson Hoyos and the HOT ROD Pontiac Sunfire of Marty Ladwig.

Extensive research and development continues on the turbocharged Ecotec and the drivetrain applications to take advantage of the global four-cylinder engine's increasing levels of horsepower. But GM Racing engineers have now turned their attention to the Pro RWD category and the development of the new high-feature GM global V-6 VVT (variable valve timing) engine being used this year in Matt Hartford's Summit Racing Chevy Cavalier.

The GM global V-6 program, an entirely new clean-sheet engine project, began in February 1999, with the first production application last June in the 2004 Cadillac CTS (followed by the Cadillac SRX, the Buick Rendezvous Ultra and the recently announced Cadillac STS and Buick Lacrosse). The V-6 VVT is designed in a family with a displacement range of 2.8L to 3.8L and architected to be either MPFI (multi-point fuel injection), turbocharged or direct injected.

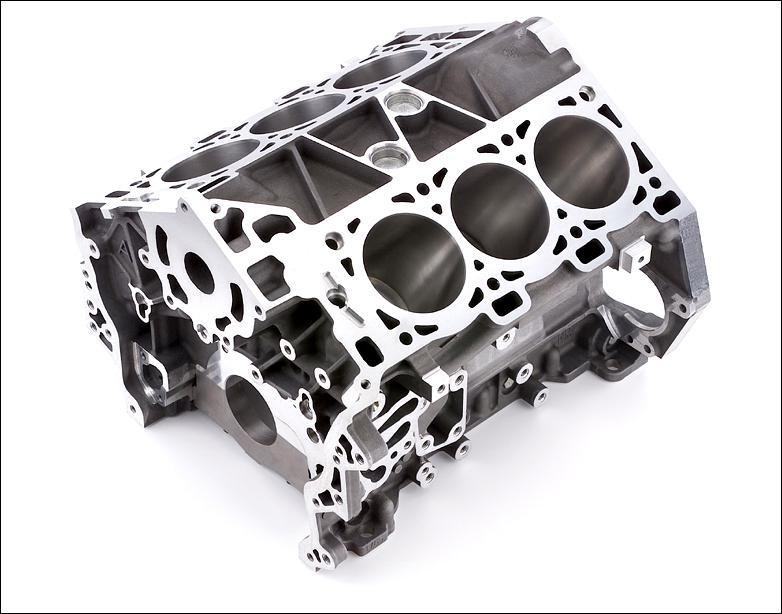

As configured, the GM global V-6 VVT is capable of being either a rear-wheel drive, transverse front-wheel drive or all-wheel drive in either a transverse or longitudinal configuration. It applies the most advanced automotive engine technology available, from state-of-the-art casting processes, to full four-cam phasing to ultra-fast data processing and torque-based engine management.

This high-tech revolutionary design delivers a market-leading balance of good specific output, high torque over a broad rpm band, superb fuel economy, low emissions and excellent noise, vibration and harshness control, with exclusive durability-enhancing features and very low maintenance.

Because of the strong, sturdy features and proven reliability of the GM global V-6 VVT, only a few modifications were needed to make the engine race-ready for Hartford's Summit Racing Chevrolet.

"There are tremendous benefits to making extreme cases of both load and speed, the kind we see in Pro RWD drag racing," said Bob Jacques, GM base engine design system engineer. "We're competing with an engine with a large percentage of production components and stressing it to well over 1650 horsepower. Therefore, it is safe to say that if the engine can stand up to this type of application then it will definitely meet the demands of the everyday driver at 250 or 260 horsepower."

In December 2003, GM engineers began working with Matt Hartford's Summit Racing team to make the high-feature GM global V-6 3.5 liter VVT engine ready to race.

"We drove the only four-cylinder car in Pro RWD last year," said Hartford. "We wouldn't have even considered the change over to the GM V-6 program if we didn't think it would provide us with the necessary horsepower to win the championship. It would have been much easier to stay with the four-cylinder, maybe add some nitrous, but get it a little more competitive, in the 6.90s or high 6.80s. We would have broken a lot of parts though, and when you see your competition running 6.68 seconds at 211 mph during testing, you realize that you need something more to be competitive again."

In January, Hartford and crew chief/engine builder Mylon Keasler arrived in Detroit and met with GM engineers to discuss the best method of getting the GM global V-6 configuration ready to race. Every component of the engine was meticulously analyzed to determine what changes were needed and where actual production parts could be used to meet the requisite horsepower levels.

With the beginning of the new season a short eight weeks away, the pressure of a tight deadline was obvious to everyone working on the project, and the speed and efficiency in which the race engine was completed was just one of many remarkable aspects of the program.

Since the NHRA limits the engine size in Pro RWD to 3.5L, decisions had to be made on how to reconfigure the production 3.6L V-6 VVT to comply with the sanctioning body's rules. An entire week was spent weighing those options, looking at 3-D models and considering the pros and cons of different design changes. The objective at GM was to take a systematic approach to find an appropriate solution instead of just cutting and chopping in an attempt to make things work.

"We spent the first week just going through computer-generated models and 3-D CAD systems, analyzing and engineering our way to where we needed to be," explained Brent Ingraham, GM design release engineer. "We came up with a couple of different combinations, starting with a base block and knocking the bore down from 94mm to 93mm. Then we went the other way and took a 94mm bore and raised it to 95mm with the idea of seeing what would work best. We then did the same thing working with a shorter stroke and then applying a production stroke."

The project team then moved on to the cylinder heads, trying to determine if production valves or larger aftermarket valves would be used, if a production combustion chamber would be utilized, or if it would be changed slightly to achieve better air flow and tumble. From the first week of January to the middle of February, 3-D models were meticulously examined matching production blocks, heads and crankshafts. Aftermarket pistons, rods, and valves were ordered, and new cam grinds provided the project team with additional options.

In the meantime, Keasler began machining crankshafts and putting short blocks together at the team's engine shop in Maryville, Tenn. Hartford and Keasler, along with team member Bob Moore and chassis builder Don Ness, had already constructed the middle and upper intake back in the middle of December because it had to fit within the carbon-fiber front-end of their new Ness-built Chevy Cavalier Cavalier.

The final race engine was eventually debored and destroked to meet the category rules. Two big twin turbos were added along with a modified upper intake, but the competition engine still maintained its production lower intake, fuel rail and head castings. Although a small liner was pressed into the block to meet the class rules of a 3.5L engine, the block casting, cylinder head castings, and crankshaft all remained production components.

The first engine assembly was completed 10 days before the schedule's first event at Fontana (Calif.), with the first dyno pull coming exactly six days before the first scheduled qualifying pass.

"When that engine started up we were absolutely thrilled," said Ingraham. "Because of all the hard work by everyone involved with this project, it's really hard to describe what we were all feeling. It was pretty exciting to see it on the dyno, have it fire up and then hear it purring like a kitten. We then took the engine apart to make sure everything looked good, reassembled it and then started applying additional load."

After the initial dyno test, the engine was torn down, rebuilt on Monday and Tuesday, and put back on the dyno Wednesday evening to make sure everything was still solid. After another successful test, the engine was loaded on the trailer and it was off to California.

"The engine ran great in Fontana, but we had some drivetrain problems because we made more power than what we anticipated," explained Ingraham. "Since Fontana, the motor's been torn down and everything looks great inside. We've had very few runs on it, so we're still learning the engine's full potential. We're now building a couple of spare engines for Palm Beach to have in our back pocket just in case we need one."

During the 2003 NHRA Pro RWD campaign, Hartford's four-cylinder 2.0L Ecotec-powered Chevy Cavalier won the NHRA Nationals at Sonoma (Calif.) was runner-up at the Northeast Nationals at Atco (N.J.), qualified for every national event and finished sixth in the Pro RWD points standings. The high-feature twin-turbo GM global V-6 has the 32-year-old Arizona resident excited about his chances for the championship in '04.

"The biggest factor is that we've gone from 120 cubic inches up to 210," said Hartford. "Since we ran 7.02 seconds at 192 mph with a four-cylinder engine, then with almost twice the size motor we should be able to run in the 6.60s at around 215 mph. Last year we had to run our program as efficiently as possible to be successful. Other teams could afford to make four or five mistakes going down the track, but we had to be spot-on perfect to have any chance of winning any rounds. Everything from the tune-up on the engine, to the tune-up on the clutch, to the gearing in the rear end was right on the edge of being as fast and as lightweight as it could be, yet strong enough to make it to the other end.

"We came into the new year and built a brand-new car with a brand-new engine program with one goal in mind - to win the championship. The new GM global V-6 now makes that possible."

GM engineers are also certain the larger high-feature global V-6 will provide the Summit Racing Chevrolet with the essential horsepower to contend for this year's championship.

"We're confident that the new engine will be competitive for its class and its power target," said Don Taylor, GM group manager of drag racing. "Matt's an exceptional driver and last year he was the only driver in Pro RWD to qualify for every race, and that was with a four cylinder engine. This year, with the GM 3.5L twin-turbo V-6, the feeling here is that the Summit Racing Chevrolet can be much more competitive and challenge for the championship.

"We race in Sport Compact to push the parts and technology to the extreme and to reach the highest performance level. With the twin-turbo V-6, we're now making over 1650 horsepower, but that's just the beginning point, not the end point. Like everything we do at GM Racing, we will continue to develop it, stress it harder and run it faster. With the performance potential of this engine, we're only beginning to scratch the surface."