Never found a thread like this in the archives. I figured it would be a good referance for those looking to do some Getrag repair themselves. I'm not going to do detailed step by step instructions. This is already done in the link below.

http://www.fieronews.net/fu...Muncie%205%20Spd.pdfI will post pics of an actual fiero Getrag from an 87GT for a more "true" idea of how to do this. I hope this is helpful to those looking for info in the future.

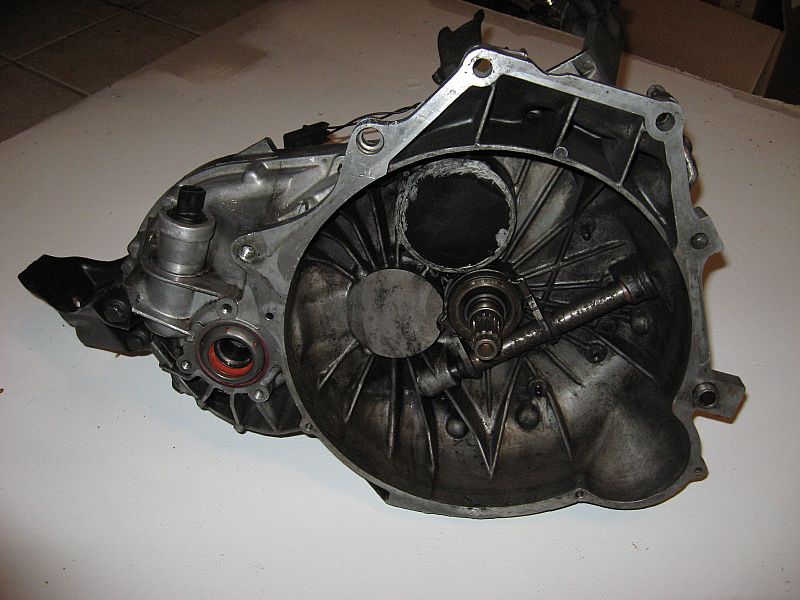

The first step to splitting a Getrag case is to remove the mounting brackets. You can't split the case with them in place. I would also recomment removing the VSS and dipstick. The shift linkage is not necissary unless you plan on further disassembly above just splitting the case.

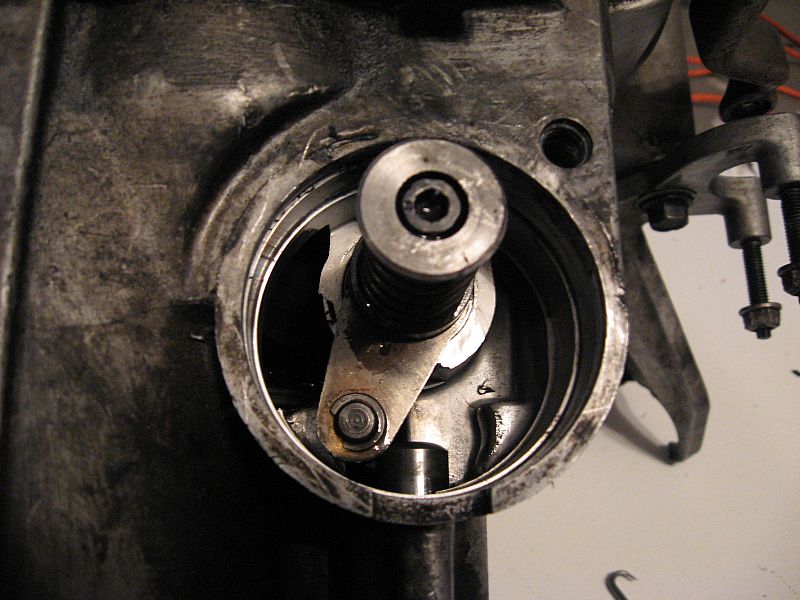

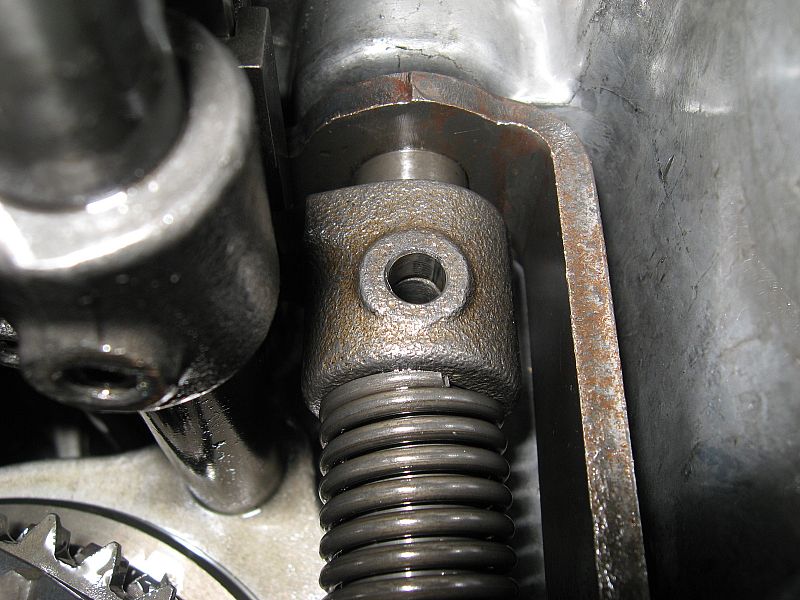

Next is the detent holder cover and shift rail detents inside the bellhousing. My cover was steel and coated with either soft plastic or hard rubber. These are stil available through GM so if you want to replace it you can pn# 14082039. Here is a shot of the cover before removal. Notice this cover has been removed before by someone in this transaxels past.

I removed this cover by prying with a small screwdriver. There were small notches around the seam I could fit the driver into. I had no intention of replacing it so I made sure to get it out in one piece.

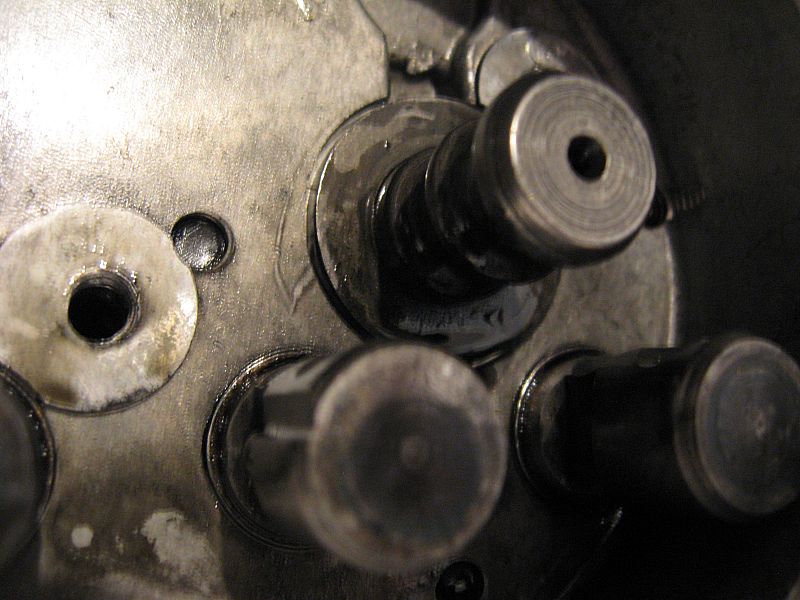

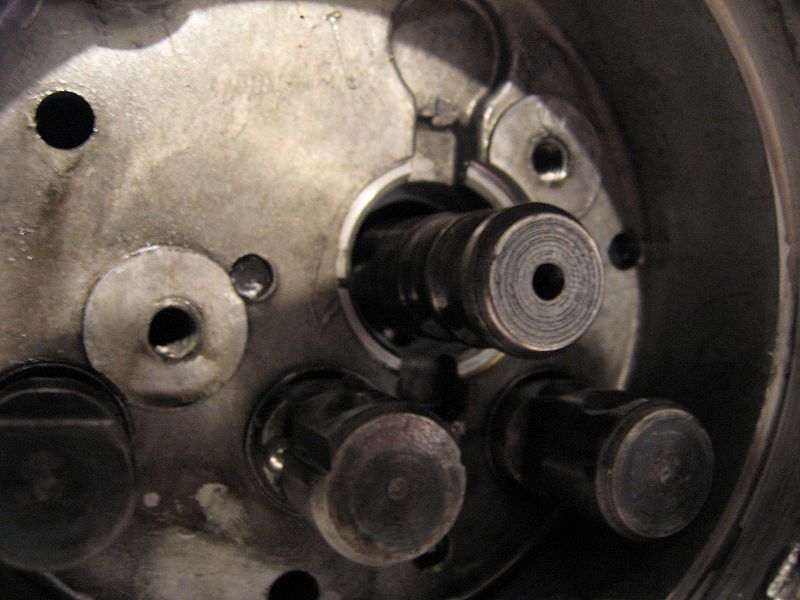

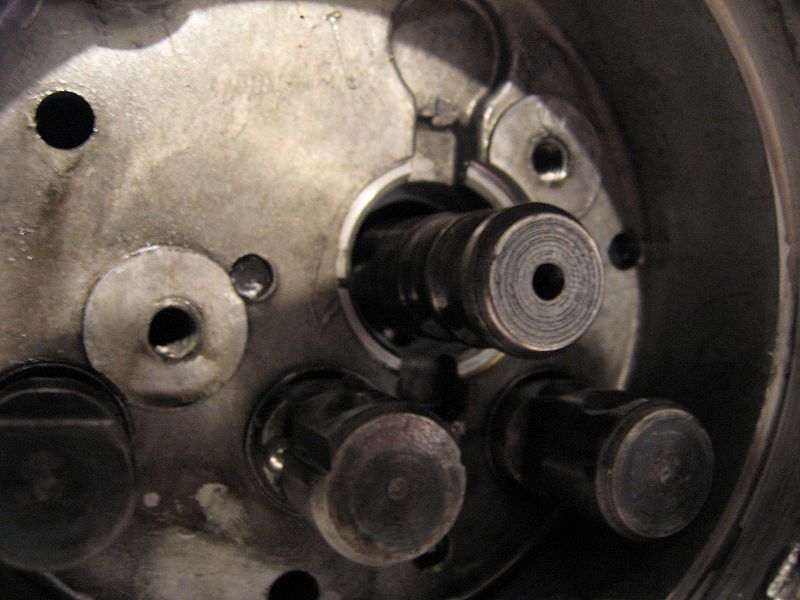

After the cover is removed you can see the detent holder and ends of the shift rails.

There are two 10mm screws that keep the detent holder, detent balls/springs (4 of each), and interlock pins (2) in place. From what I have read some of the earlier models also had an interlock plate that goes on top of the detent holder. Mine did not. If your detent holder is not at least 18mm thick you should have interlock plate in place.

Be sure not to lose any of the balls or springs.

There is also a bushing on the reverse rail. This comes out very easily by using a couple of small allen wrenches to pry it off. There are notches to pry from. You can't miss them.

With the detent assembly removed you can now remove the fifteen 13mm bolts that hold the bellhousing to the trans case.

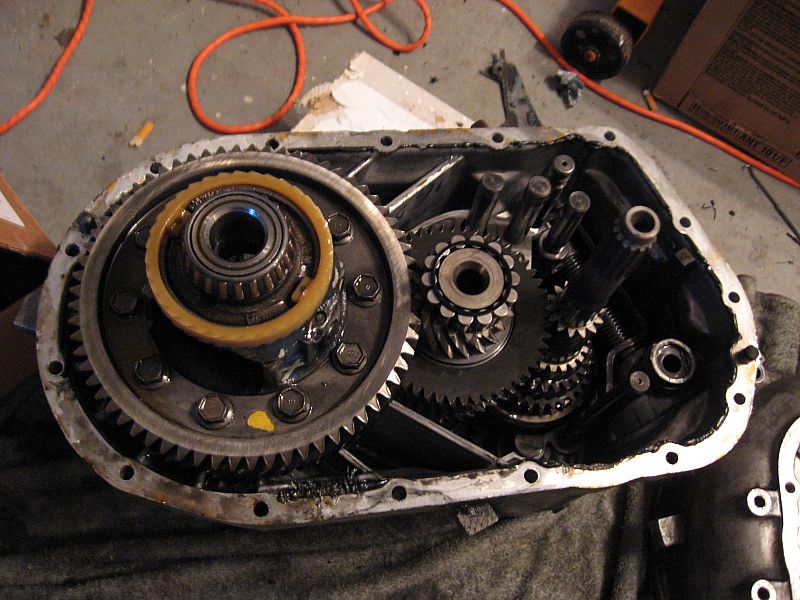

Once all the bolts are out take a rubber mallet and tap the case to crack the seal. Locktite 518 anerobic sealer is used from the factory, PN 1052942. Mine was put together with silicone from whoever had been into it before. Turn the trans so the bellhousing is face up. Now you can lift off the case. There are two dowel pins also so keep that in mind.

Be careful. The output shaft bearing may stick to the bellhousing. Just keep an eye on it so it doesn't fall into the case or onto the floor.

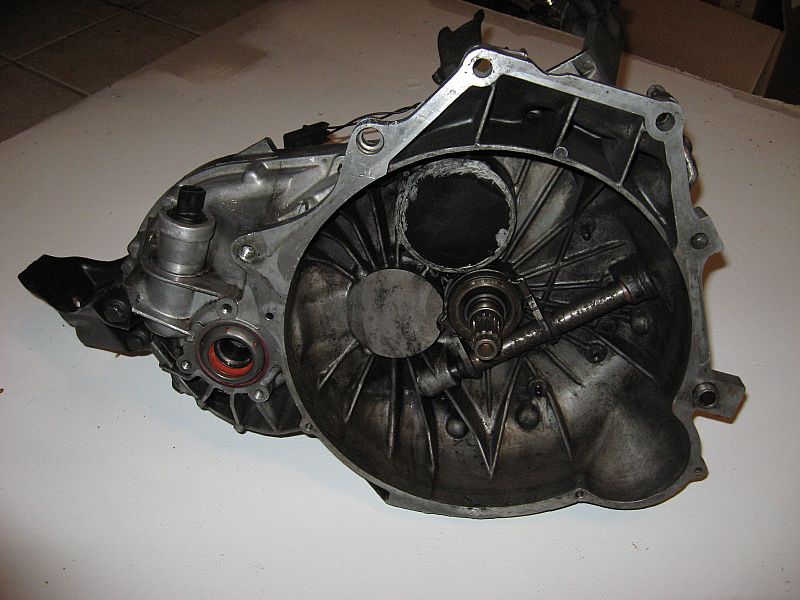

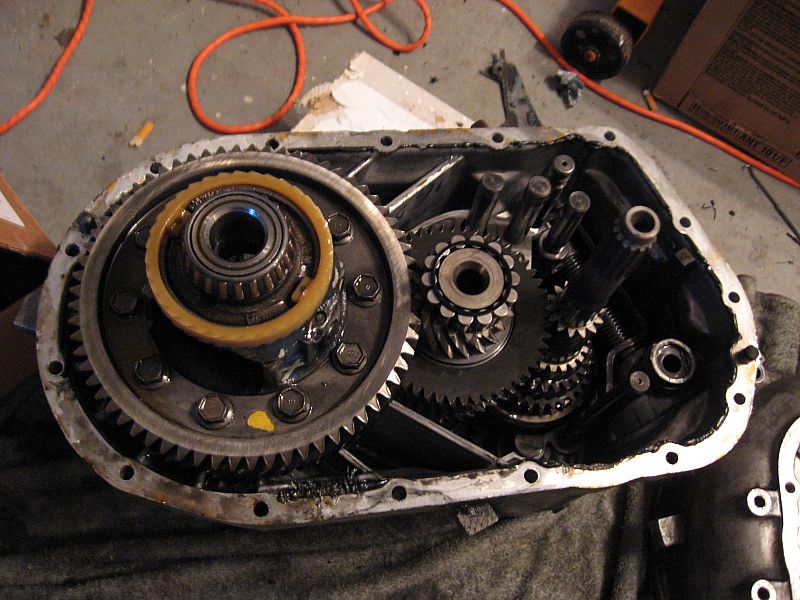

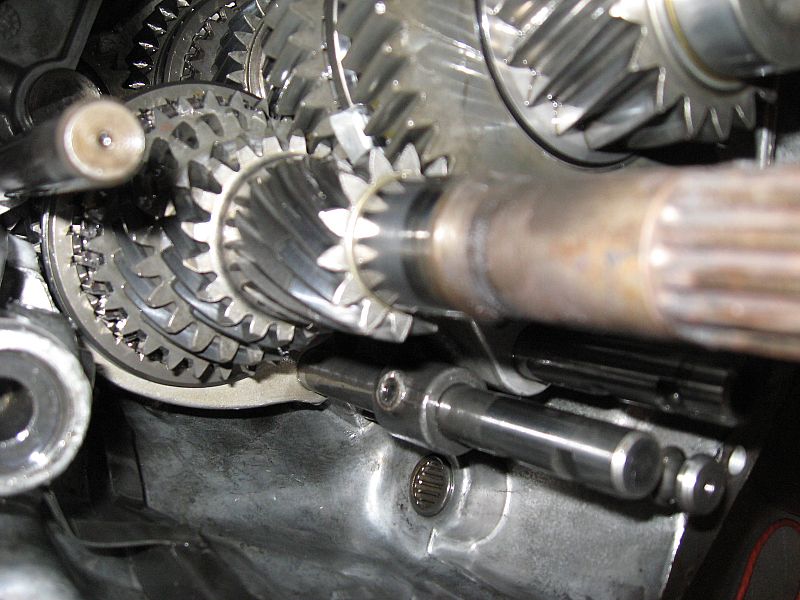

Bellhousing half

Gearbox half

Thats how you split a Getrag case. Hope this takes some of the mystery out of the process. Enjoy!

EDIT 12-11-09

--------------------------------------------------------------------------------------------------------------------------

Probing deaper at the request of several members.

First step to going deeper in is to remove the outer shift linkage. Technically you should have done this before splitting the case if your plan was to dig deeper into the getrag.

Put the trans in neutral and grab yourself a 21mm socket, 1/2" drive rachet, and can of your favorite penatrating liquid. Soak the nut good as they are usually rusty given the age of these transaxels. Hold tight onto the shift lever while loosening the nut. According to the getrag manual liked above you do not want the shift rail to move while loosening the nut.

Once the nut is removed take off the washer and shift lever. The next step is to remove the pivot pin for the select lever. Remove the small chip and the pin should slide right out. Check for wear in the pin and bushings. If the plastic bushings are missing or broken replace them. A select arm rebuild kit from Rodneydickman.com is the best of the best for replacements. You can also remove the two 13mm bolts that hold on the pivot pin bracket in place. This is not necissary unless you are replacing the shift rail seal.

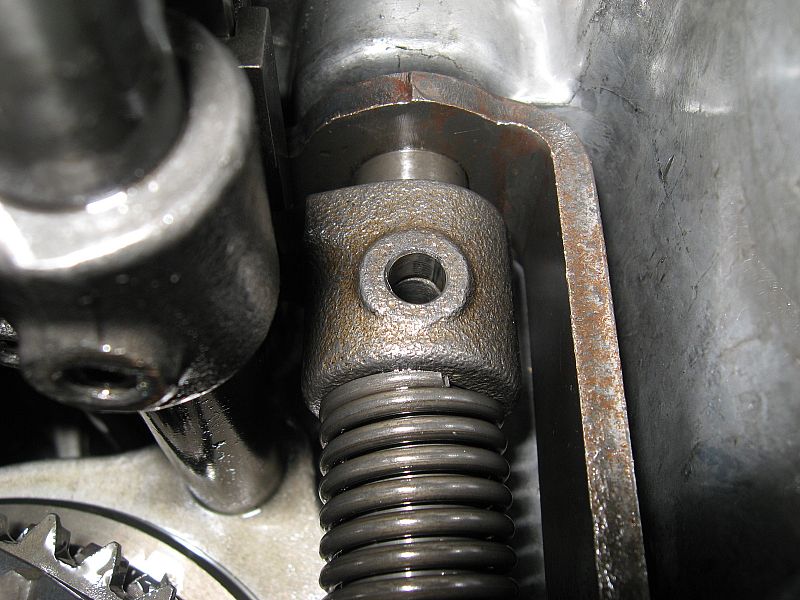

Next part is the pivot collar that slids onto the shift rail. This is held in place with a roll pin. A hammer and 3/16" punch are ideal for removing it. Wipe down the shfit rail threads real good. Check for anything that may keep it from being removed easily, especially if you plan on reusing the seal for it. Use an extremely fine file if you need to remove some burs but be very careful. It must be smooth to slide out properly.

Collar pin located here...

Removed parts. Notice one of my select pin bushings is broken. Going to give Rodney a call for a rebuild kit.

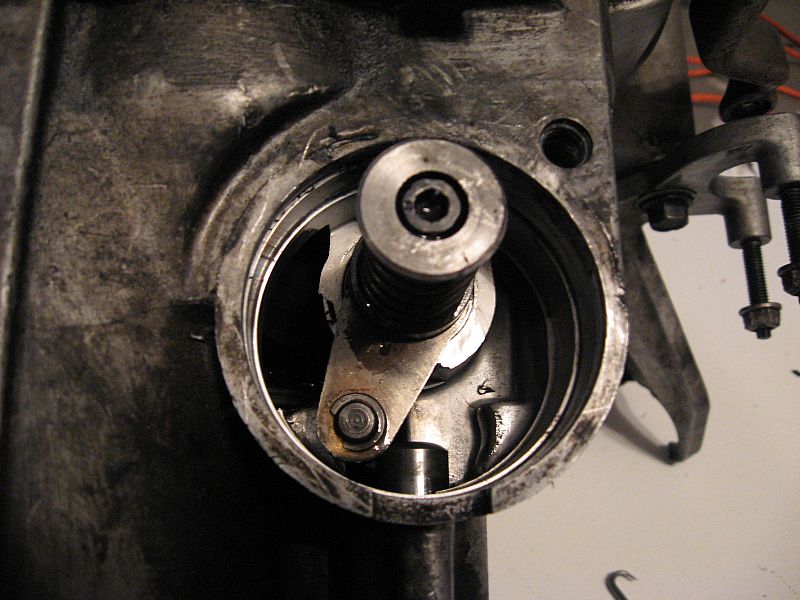

Next up is the removal of the shift rail itself. There are a few steps to this process. First, flip the trans over and find this black cover at the other end of the shift rail. It is held in place with a relatively large "C" clip. A screwdriver workes well to remove the clip and a rubber mallet works on the cover. My cover was also siliconed in place so it was extra fun to remove.

Clip

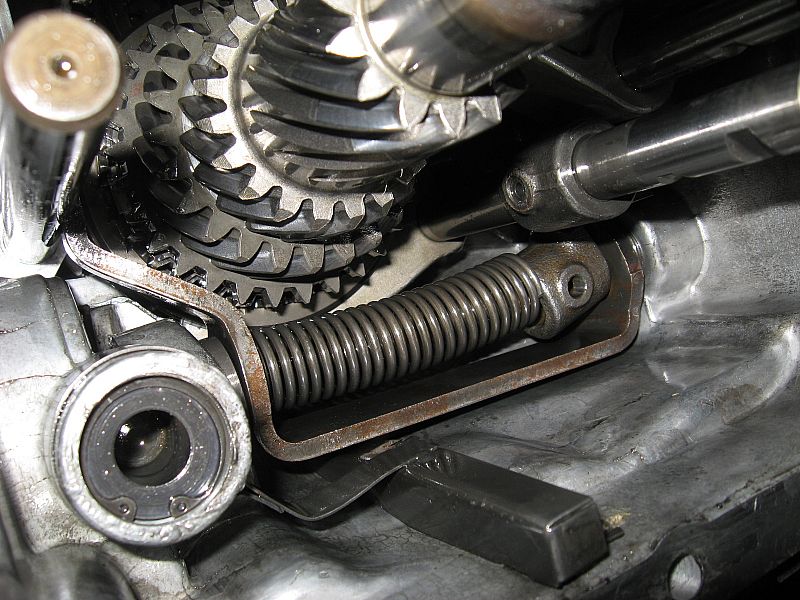

Under the cover you find the shift shaft detent assembly. Included in this is the 5th/reverse bias spring and inner/outer spring seats. Use a 5mm allen wrench or equivelant to remove screw that holds the outer spring seat in place. The spring and inner set come right out after that.

If you haven't split the case yet now is the time....

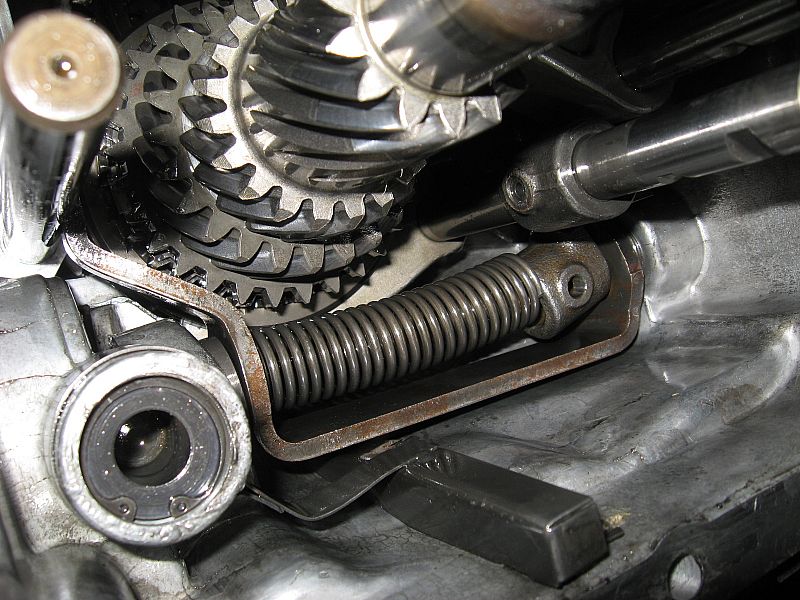

The next part of removing the shift rail is to remove the reverse lever from inside the case. Again it is held in place with a 3/16" rollpin. There is also a spring and the shift lever collar held by the pin. Again use the hammer and 3/16 punch to remove the pin. It may help to engage 4 gear to get the pin in a better position. This is done by pressing down on the 3/4 shift rail. When you get the punch on it the pin will probably fall into the case... unless you have magic fingers.

Don't worry about it. It can be retrived later. Better to replace all the pins with new ones anyway.

Reverse lever/spring/shift lever (pin removed).

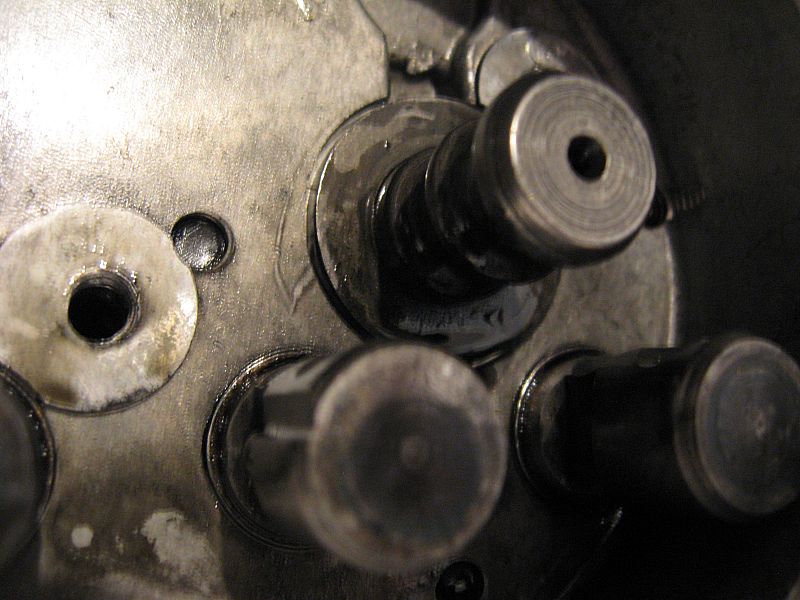

Upclose shot of pin location.

Wiggle the reverse lever out of its position. Now you can slowly and gently slide out the shift rail. Take care not to lose the detent rollers (x4) and pins (x2) while sliding out the rail.

Pic of parts.

Where the rail used to be...

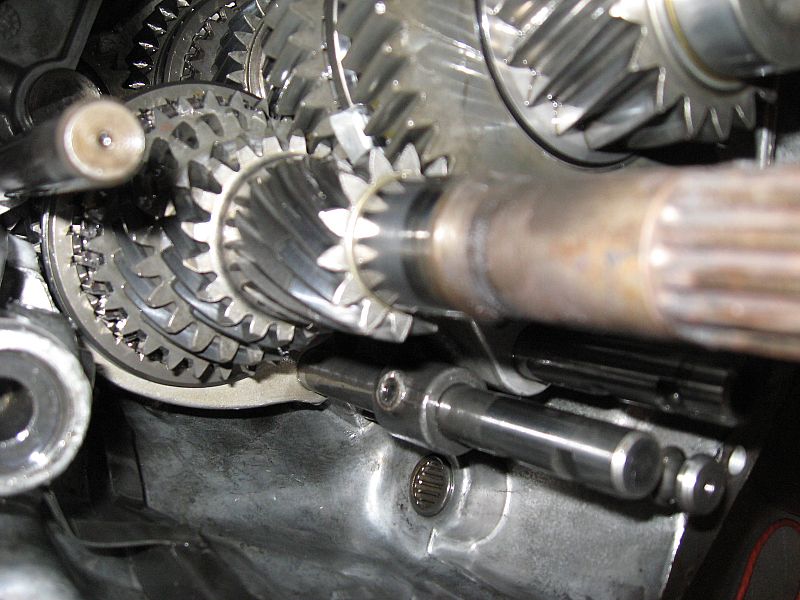

Next up is the removal of he input/putput bearing retainers.

First engage the 4th and reverse shift rails by pressing down on them. This will lock the trans so the bearing retainers can be removed. To get to the retainers you first have to remove the outer steel cover. There are nine 13mm bolts that hold it in place then tap with you rubber mallet. Under the cover is what the manual refers to as an "oil shield" that sits on top of the output shaft shim. The shim can also fall out so take care not to lose it.

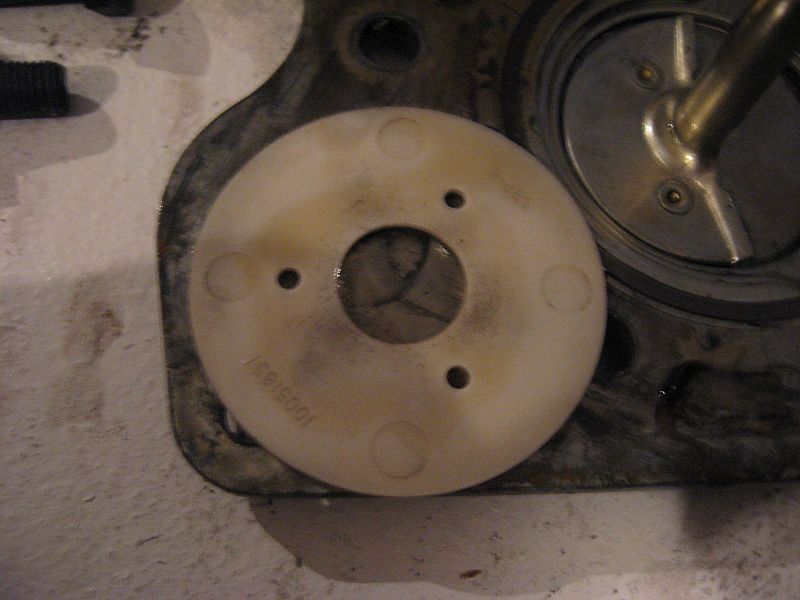

Ever wondered what was under that steel cover on the end of a Getrag?

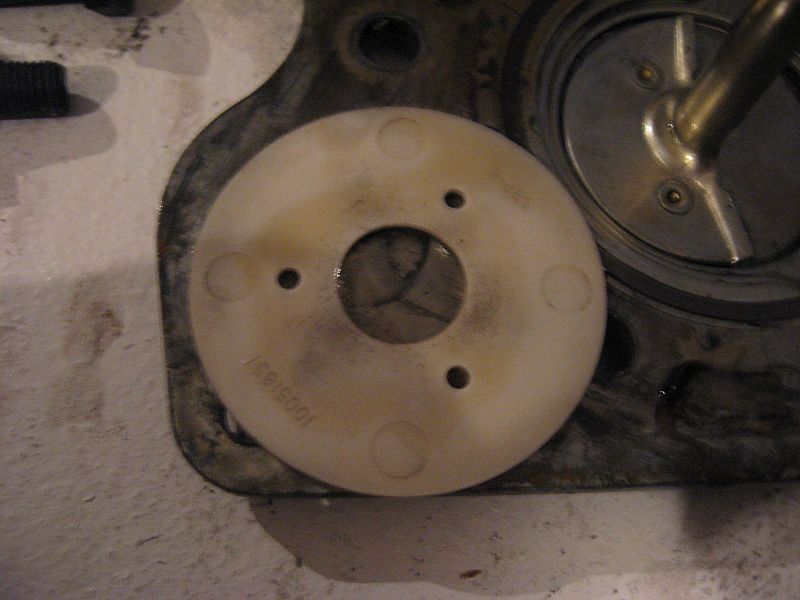

Oil shield. Its just a plastic disc with a few small holes in it.

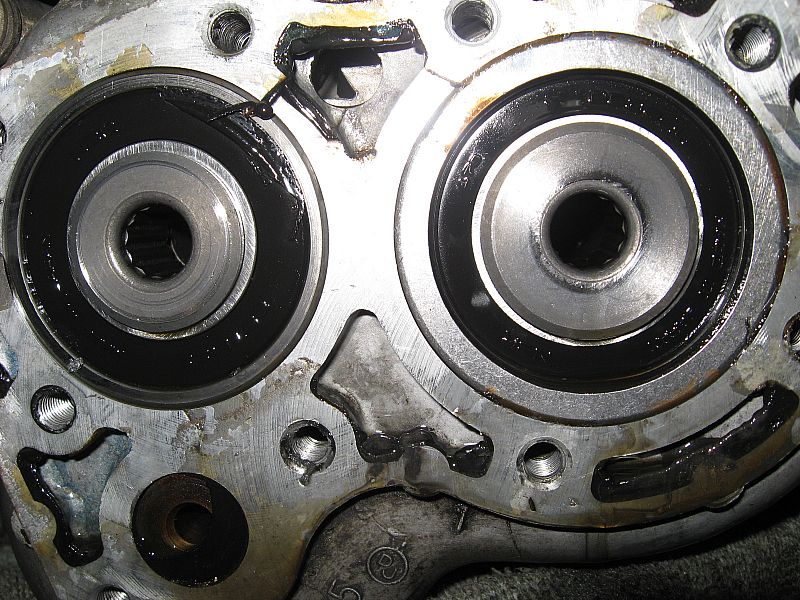

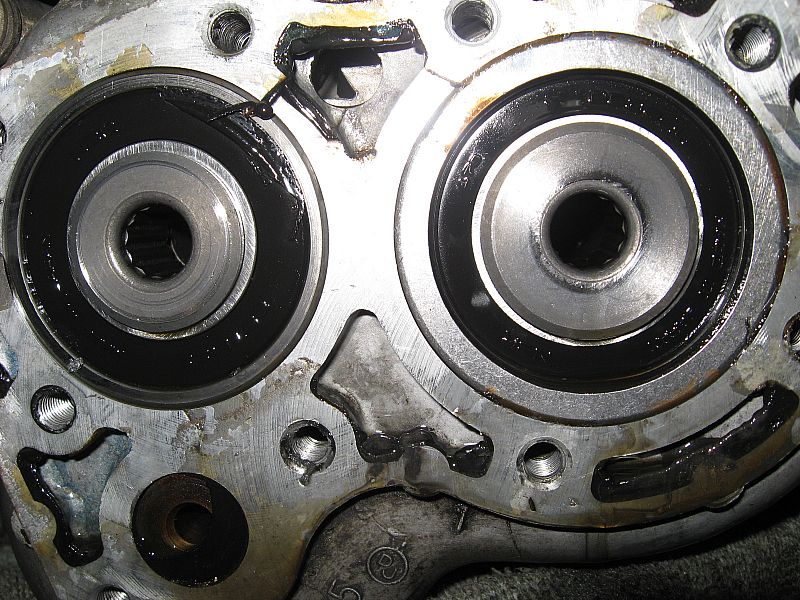

Input & output shaft bearings with retainers inplace. The output shaft shim is still in place in this pic also. Output shaft on the right.

Now you can remove the bearing retainers. The manual says use special tool J36031 or equivalent. Its nothing special, actually just a 1/2" drive 12mm allen socket. The input shaft retainer (left) spins counter clockwise to remove. The output shaft retainer (right) spins clockwise to remove. They are torqued to 85 ft/lbs with locktite to keep them there. Use a large breaker bar to remove them. They are tough.

That is as far as I went with this trans as the moment. To remove the gear clusters you need a 15 ton press. Hope you enjoyed this addition. I'll do a new thread when I actually get around to the rebuild. It may be a while. Fiance is getting layed off end of this month. That pretty much means I have no free money anymore. Later.

[This message has been edited by Fieroseverywhere (edited 12-15-2009).]