1999 Chevrolet Corvette

--------------------------------------------------------------------------------

Ignition System Overview

The electronic ignition system controls fuel combustion by providing a spark to ignite the compressed air/fuel mixture at the correct time. To provide optimum engine performance, fuel economy, and control of exhaust emissions, the PCM controls the spark advance of the ignition system. The Electronic ignition system has the following advantages over a mechanical distributor system:

No moving parts

Less maintenance

Remote mounting capability

No mechanical load on the engine

More coil cool down time between firing events

Elimination of mechanical timing adjustments

Increased available ignition coil saturation time

The electronic ignition system does not use the conventional distributor and coil. The ignition system consists of the following components/circuits:

Eight ignition coils/modules

Eight Ignition Control (IC) circuits

Camshaft Position (CMP) sensor

1X Camshaft reluctor wheel

Crankshaft Position (CKP) sensor

24X Crankshaft reluctor wheel

Related connecting wires

Powertrain Control Module (PCM)

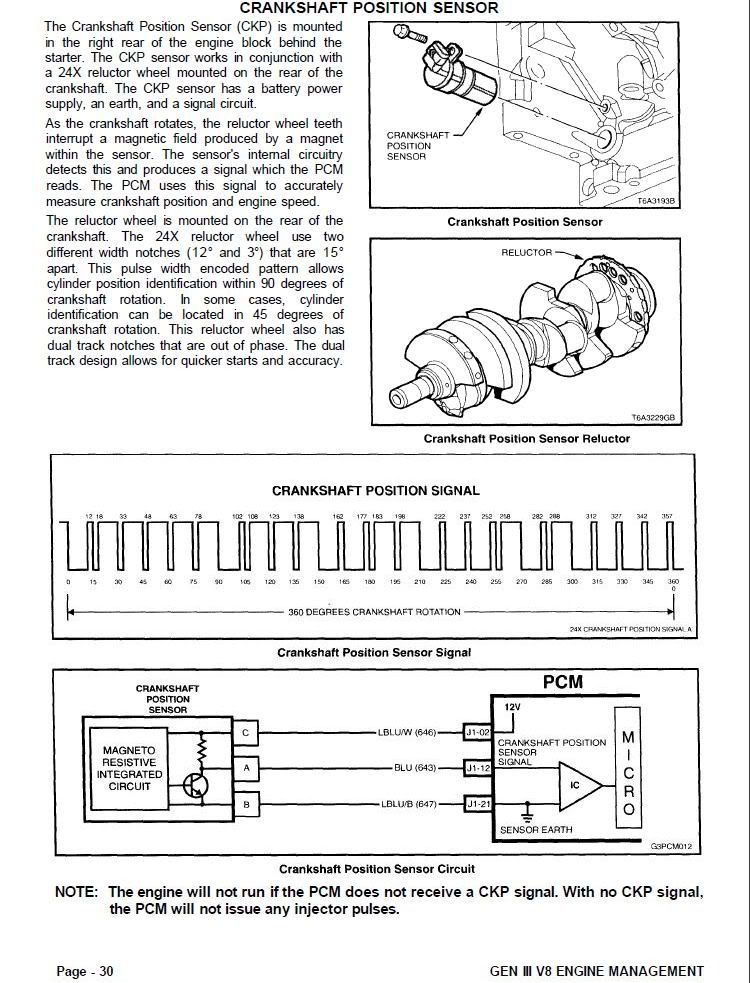

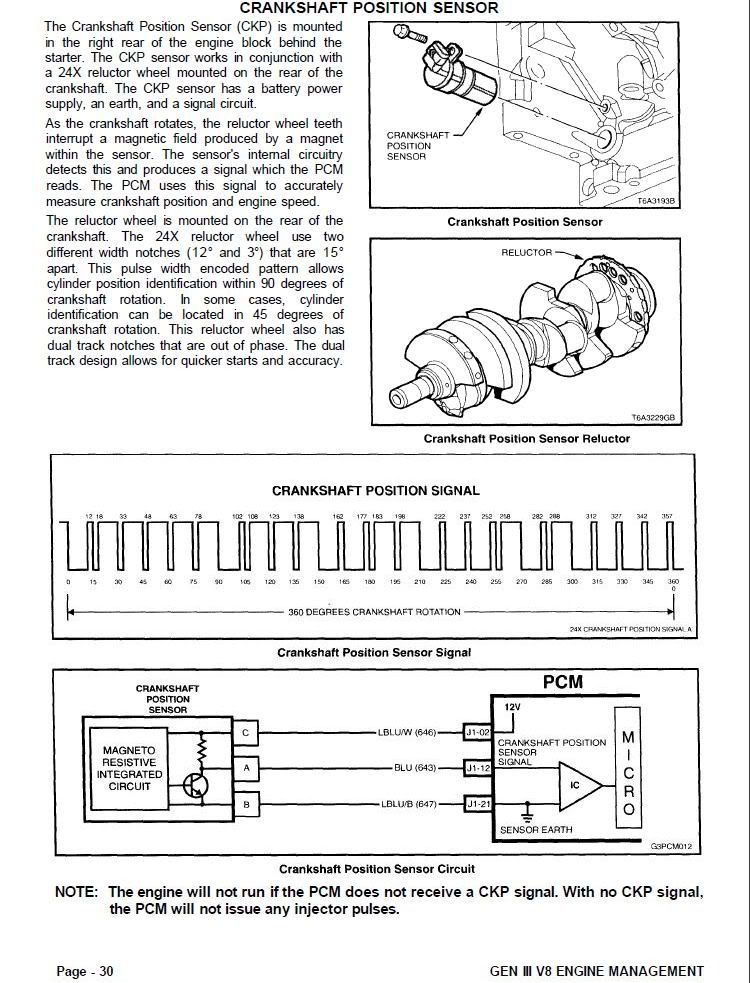

Crankshaft Position Sensor and Reluctor Wheel

The crankshaft position (CKP) sensor is located in the right rear of the engine, behind the starter. The CKP sensor is a dual magneto resistive type sensor. The dual micro switches monitor both notches of the reluctor wheel for greater accuracy. The CKP sensor works in-conjunction with a 24X reluctor wheel. The reluctor wheel is mounted on the rear of the crankshaft. The 24X reluctor wheel uses 2 different width notches that are 15 degrees apart. This pulse width encoded (PWE) pattern allows cylinder position identification within 90 degrees of crankshaft rotation. In some cases, cylinder identification can be located in 45 degrees of crankshaft rotation. This reluctor wheel also has dual track notches that are 180 degrees out of phase. The dual track design allows for quicker starts and accuracy.

The PCM also receives a 4X signal from the CKP sensor. The PCM utilizes the 4X signal for the following:

Misfire

Tachometer output

Spark control

Fuel control

Certain diagnostics

The CKP signal must be available for the engine to start. The CMP signal is not needed to start and operate the engine. The PCM can determine when a particular cylinder is on either a firing or exhaust stroke by the 24X signal. The CMP sensor is to determine what stroke the engine is on. The system will attempt synchronization and look for an increase in the MAF signal. An increase in the MAF signal indicates the engine has started. If the PCM does not detect an increase in the MAF signal, a re-sync will occur to the opposite cam position. A slightly longer cranking time may be a symptom of this condition.

Camshaft Position Sensor

The camshaft position (CMP) sensor is mounted through the top of the engine block at the rear of the valley cover. The CMP sensor works in conjunction with a 1X reluctor wheel. The reluctor wheel is located at the rear of the camshaft. The CMP sensor is used to determine whether a cylinder is on the firing or the exhaust stroke. As the camshaft rotates, the reluctor wheel interrupts a magnetic field produced by a magnet within the sensor. The CMP sensor internal circuitry detects this and produces a signal which is used by the PCM. The PCM uses this signal in combination with the CKP 24X signal to determine crankshaft position and stroke.

The CKP signal must be available for the engine to start. The CMP signal is not needed to start and operate the engine. The PCM can determine when a particular cylinder is on either a firing or exhaust stroke by the 24X signal. The CMP sensor is to determine what stroke the engine is on. The system will attempt synchronization and look for an increase in the MAF signal. An increase in the MAF signal indicates the engine has started. If the PCM does not detect an increase in the MAF signal, a re-sync will occur to the opposite cam position. A slightly longer cranking time may be a symptom of this condition.

Ignition Coils/Module

The ignition system on this vehicle features a multiple coil ignition and is known as coil near plug. The secondary ignition wires are short compared with a distributor ignition system wire. The 8 ignition coils/modules are individually mounted above each cylinder on the rocker covers. The coils/modules are fired sequentially. There is an ignition control (IC) circuit for each ignition coil/module. The 8 ignition control circuits are connected to the PCM. All timing decisions are made by the PCM, which triggers each coil/module individually. The ignition coil/modules are supplied with the following circuits:

Ignition feed circuit

Ignition control circuit

Ground circuit

Reference low circuit

The ignition feed circuits are fused separately for each bank of the engine. The 2 fuses also supply the injectors for that bank of the engine. Each coil/module is serviced separately.

This system puts out very high ignition energy for plug firing. Because the ignition wires are shorter, less energy is lost to ignition wire resistance. Also, since the firing is sequential, each coil has seven events to saturate as opposed to the three in a waste spark arrangement. Futhermore, no energy is lost to the resistance of a waste spark system.

Circuits Affecting Ignition Control

To properly control ignition timing, the PCM relies on the following information:

Engine load (manifold pressure or vacuum)

Atmospheric (barometric) pressure

Engine temperature

Intake air temperature

Crankshaft position

Engine speed (RPM)

The ignition control (IC) system consists of the following components:

Ignition coil/modules

24X crankshaft position sensor

Powertrain Control Module (PCM)

All connecting wires

The Ignition Control utilizes the following to control spark timing functions:

24X signal -- The 24X crankshaft position sensor sends a signal to the PCM. The PCM uses this signal to determine crankshaft position. The PCM also utilizes this signal to trigger the fuel injectors.

Ignition Control (IC) circuits -- The PCM uses these circuits to trigger the ignition coil/modules. The PCM uses the crankshaft reference signal to calculate the amount of spark advance needed.

Noteworthy Ignition Information

There are important considerations to point out when servicing the ignition system. The following noteworthy information will list some of these, to help the technician in servicing the ignition system.

The ignition coils secondary voltage output capabilities are very high -- more than 40,000 volts. Avoid body contact with ignition high voltage secondary components when the engine is running, or personal injury may result!

The 24X crankshaft position sensor is the most critical part of the ignition system. If the sensor is damaged so that pulses are not generated, the engine will not start!

Crankshaft position sensor clearance is very important! The sensor must not contact the rotating interrupter ring at any time, or sensor damage will result. If the interrupter ring is bent, the interrupter ring blades will destroy the sensor.

Ignition timing is not adjustable. There are no timing marks on the crankshaft balancer or timing chain cover.

Important

Never pierce a secondary ignition wire or boot for any testing purposes.

Be careful not to damage the secondary ignition wires or boots when servicing the ignition system. Rotate each boot to dislodge it from the plug or coil tower before pulling it from either a spark plug or the ignition coil. Future problems are guaranteed if pinpoints or test lights are pushed through the insulation for testing.

Powertrain Control Module (PCM)

The PCM is responsible for maintaining proper spark and fuel injection timing for all driving conditions. To provide optimum driveability and emissions, the PCM monitors input signals from the following components in calculating ignition control (IC) spark timing:

Engine Coolant Temperature (ECT) sensor

Intake Air Temperature (IAT) sensor

Mass Air Flow (MAF) sensor

Knock Sensor

Trans Range inputs from Transaxle Range switch

Throttle Position (TP) sensor

Vehicle Speed Sensor (VSS)

Results of Incorrect Operation

An Ignition control circuit that is open, grounded, or short to voltage will set an ignition control circuit DTC. If a fault occurs in the IC output circuit when the engine is running, the engine will experience a misfire. DTCs P0351-P0358 will set when a malfunction is detected with an Ignition Control circuit. When an Ignition control DTC sets, the PCM will disabled the injector for the appropriate cylinder.

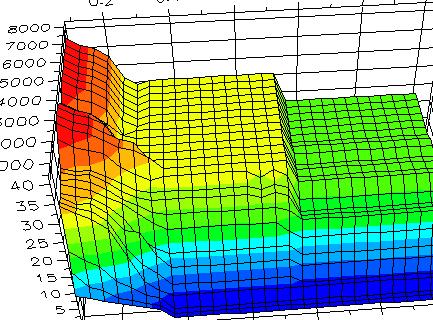

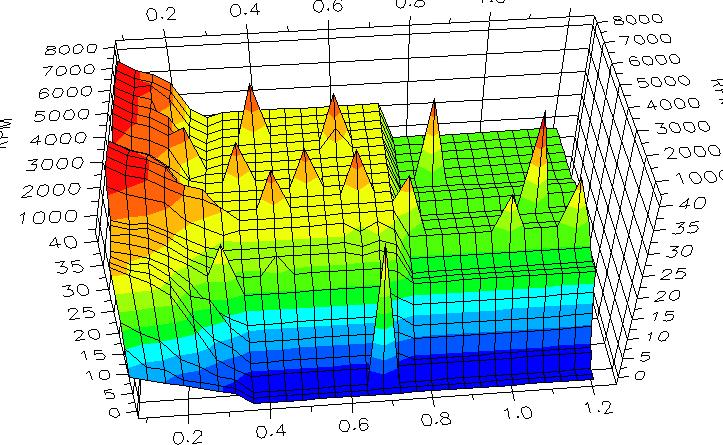

The PCM uses information from the engine coolant temperature sensor in addition to RPM to calculate spark advance values as follows:

High RPM = more advance

Cold engine = more advance

Low RPM = less advance

Hot engine = less advance

Therefore, detonation may be caused by high resistance in the engine coolant temperature sensor circuit. Poor performance may be caused by low resistance in the engine coolant temperature sensor circuit.

If the engine cranks but will not run or immediately stalls, Engine Cranks But Will Not Run diagnostic table must be used to determine if the failure is in the ignition system or the fuel system. If DTC P0300, P0341, P0342, P0343, P0335, P0336 is set, the appropriate diagnostic trouble code table must be used for diagnosis.

--------------------------------------------------------------------------------

[This message has been edited by AJxtcman (edited 02-09-2011).]