|

|

|

|

LS1 PCM on a Northstar by AJxtcman

| Started on | : 11-11-2007 09:38 PM |

| Replies | : 272 |

| Last post by | : Will on 03-14-2012 07:42 AM |

|

|

|

|

May 31st, 2011

|

CalibrationEditor

Member Posts: 33

From: Rock Hill SC

Registered: Mar 2010

|

Hey Will I will post the 272 cam card I got and promissed not to post. Just wait until you see it

IP: Logged

|

03:27 PM

|

|

CalibrationEditor

Member Posts: 33

From: Rock Hill SC

Registered: Mar 2010

|

.  [This message has been edited by CalibrationEditor (edited 05-31-2011).]

IP: Logged

|

05:54 PM

|

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

AJ, that's cool. Salem is only 45 minutes away from my place. if you come out, please let me know, eh. [This message has been edited by IXSLR8 (edited 05-31-2011).]

IP: Logged

|

09:28 PM

|

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

| | | quote | Originally posted by Will:

Have you verified the mechanical condition of your engine? Leak-down test each cylinder and watch for bubbles at the coolant fill point? |

|

Yes, it has good compression. Has perfect heads. Did a leak down test last year. Sealed well with Cometic gaskets, studs and inserts. Rebuilt stock injectors, new sensors all way round. 53K miles on the engine when I bought it. Didn't see anything unusual when I resealed the case halfs and did the studs in the heads. However, noticed a lifter noise after coming home from the beach this weekend. Going to have to figure out which one it is out of 32 of them. [This message has been edited by IXSLR8 (edited 05-31-2011).]

IP: Logged

|

09:40 PM

|

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

Did you run the specs when you installed the cams?

IP: Logged

|

11:19 PM

|

|

|

Jun 1st, 2011

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

Yes, it was after I put the cams in that the tests were done.

IP: Logged

|

02:54 AM

|

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

Did you bolt a degree wheel to the balancer and measure the lift curve to verify that the cams were installed as advertised?

IP: Logged

|

08:26 AM

|

|

CalibrationEditor

Member Posts: 33

From: Rock Hill SC

Registered: Mar 2010

|

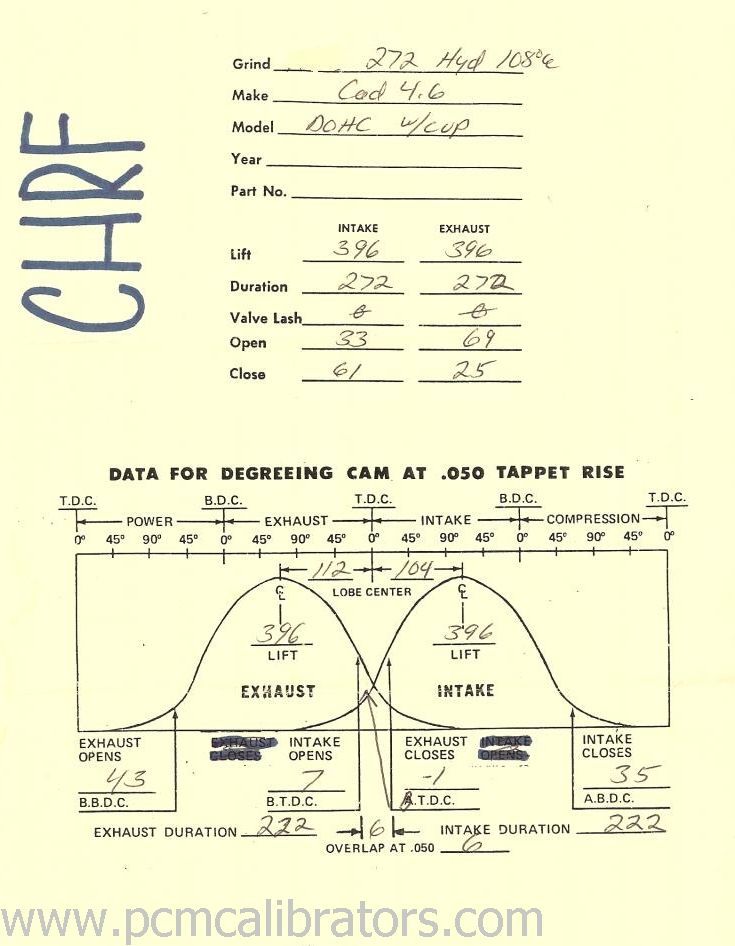

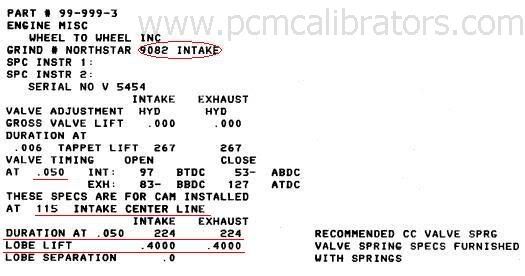

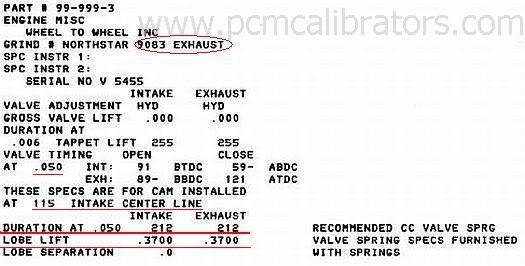

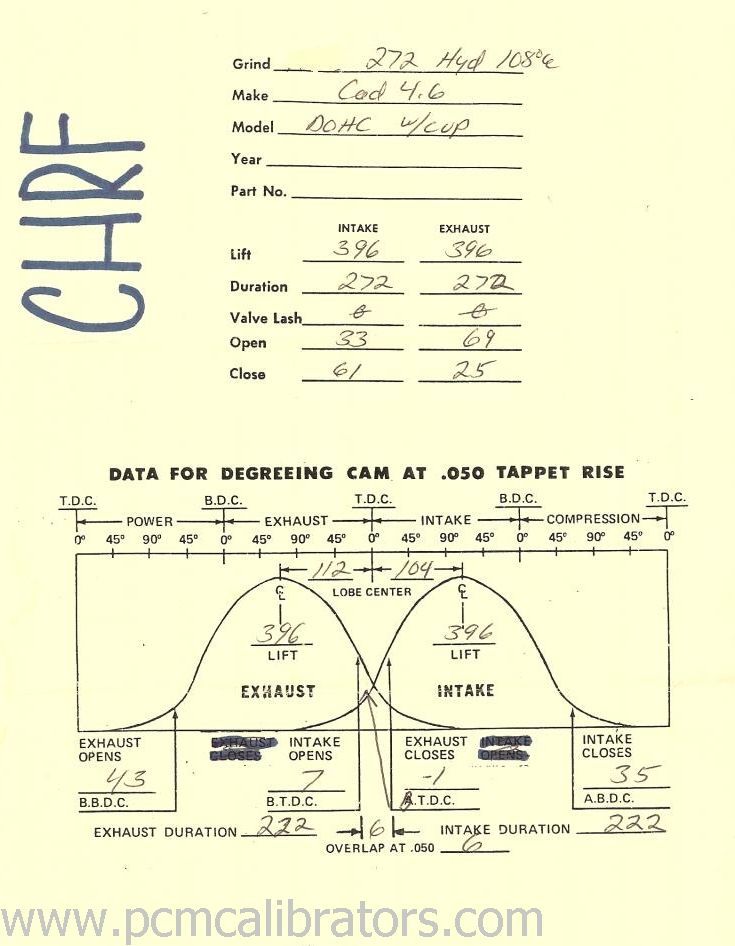

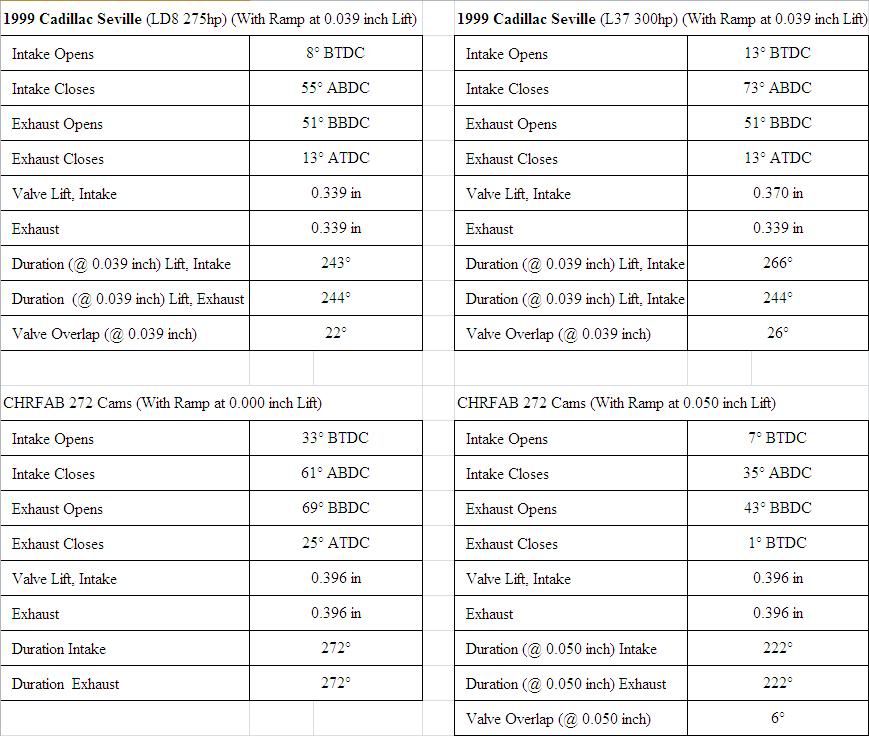

Will he could not get the cam specs from Alan at CHRFAB. I got them from a 3rd party.

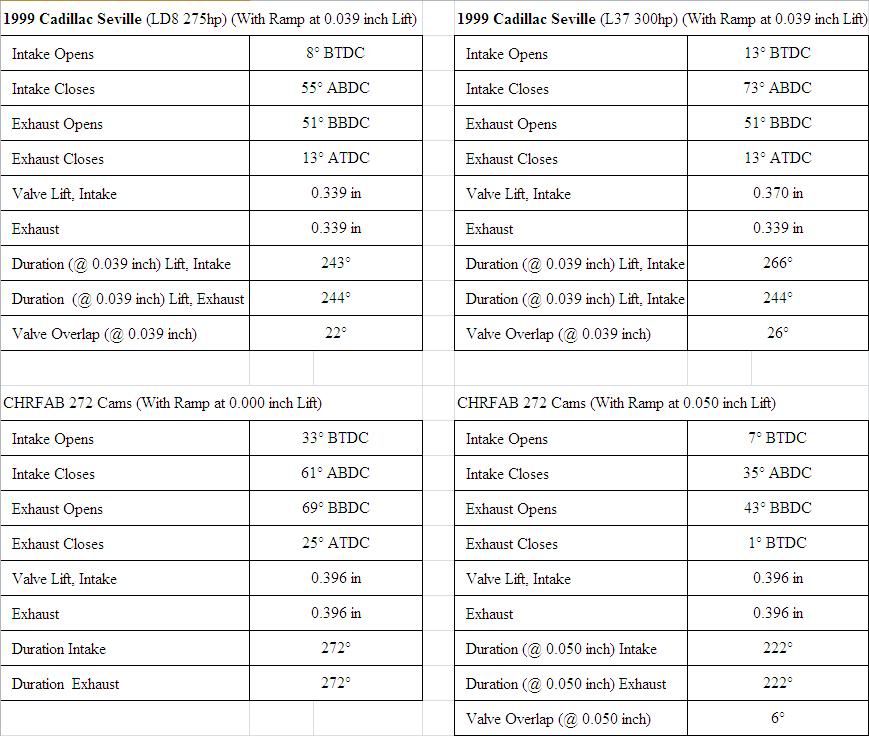

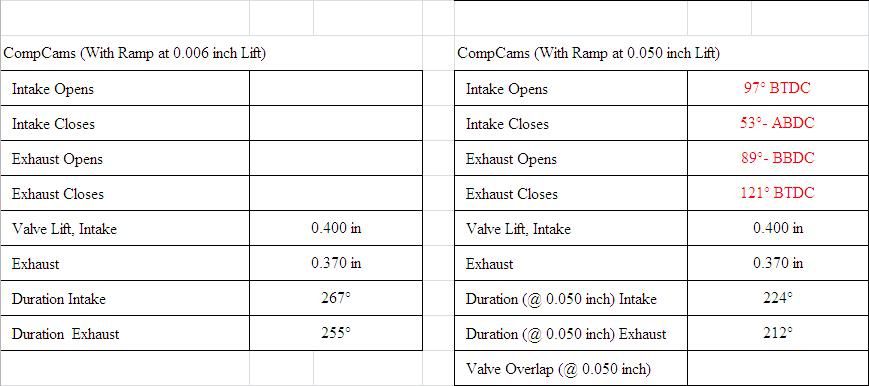

Look at the spec really closed. Look at the .050 vs the stock .039 and just think about it.

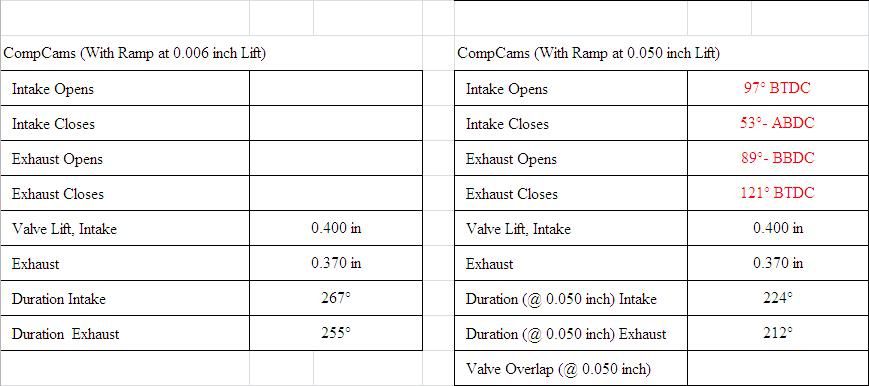

I had a set of 4 Comp Cams that I sold a few months back and those spec are all f'd up. I will dig them up and post them also.

How much bigger are the 272° over the stock cams. Yes you will have to guess

IP: Logged

|

01:11 PM

|

|

CalibrationEditor

Member Posts: 33

From: Rock Hill SC

Registered: Mar 2010

|

IP: Logged

|

01:16 PM

|

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

no, unfortunately.

IP: Logged

|

02:21 PM

|

|

CalibrationEditor

Member Posts: 33

From: Rock Hill SC

Registered: Mar 2010

|

I know I am beating a dead horse, but really look at these. Just ignor the bad specs in the Comp Cams. .   [This message has been edited by CalibrationEditor (edited 06-01-2011).]

IP: Logged

|

06:34 PM

|

|

|

PFF

System Bot

|

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

Did you try the competition cams in a Northstar? It would be interesting to see if the same results are plaguing the owner who uses them in a GM program application.

Summarize for me, what the problem with the CHRF cams are, could you? Not much over stock, right? Mild.

My understanding is that my cams are reground for the CHRF way, that is, the approach that Alan likes to run them with a Holley 950 as opposed to a common GM program. I was told by Howell that the stock caddy computer can handle 272 cams but NO more than that duration. I didn't ask what Brand/Vendor which is my big mistake in this whole process.

And another piece of info...the previous owner of the 272 CHRF cams that I'm running (the person I bought them from) ran them in his N* with the Holley 950 system. He told me recently that with his tune he had approximately 360 HP at the crank. The reason he sold them to me is that he upgraded to 288 cams.

IP: Logged

|

08:14 PM

|

|

fieroguru

Member Posts: 12436

From: Champaign, IL

Registered: Aug 2003

|

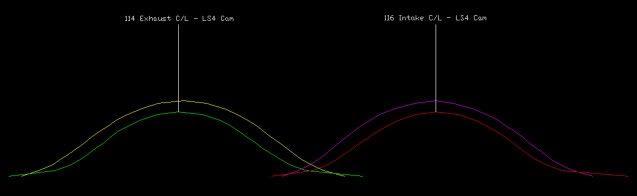

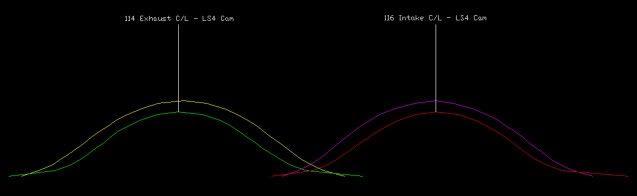

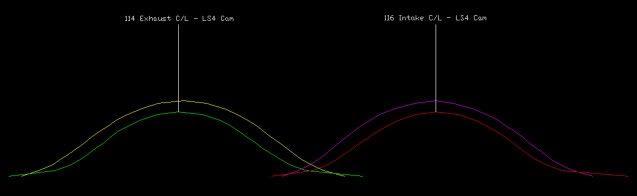

You can't have a meaningful comparison between a stock ground cam and an aftermarket one unless you measure both cams at the same intervals. The .039" of the stock compared to the .050 of the aftermarket ones will almost always show more duration, simply because it is closer to the base circle and GM lets their valves open/close at very slow rates. Also the you really need to compare the cams at .200 to .400 lift ranges to see which has the larger duration. Here is an example of how lazy and wide the stock cam vs. my aftermarket cam (not an N*, but and LS4). I used a degree wheel and plotted both cams at .006, .025, .050, .075 and every .025 interval from open to peak to close and graphed the relative differences. You will notice that the .006 and .025 values on the stock cam are very, very wide and wider than my aftermarket cam with almost 30+ degrees more duration than at .050.

IP: Logged

|

08:48 PM

|

|

|

Jun 2nd, 2011

|

CalibrationEditor

Member Posts: 33

From: Rock Hill SC

Registered: Mar 2010

|

| | | quote | Originally posted by IXSLR8:

Did you try the competition cams in a Northstar? It would be interesting to see if the same results are plaguing the owner who uses them in a GM program application.

Summarize for me, what the problem with the CHRF cams are, could you? Not much over stock, right? Mild.

My understanding is that my cams are reground for the CHRF way, that is, the approach that Alan likes to run them with a Holley 950 as opposed to a common GM program. I was told by Howell that the stock caddy computer can handle 272 cams but NO more than that duration. I didn't ask what Brand/Vendor which is my big mistake in this whole process.

And another piece of info...the previous owner of the 272 CHRF cams that I'm running (the person I bought them from) ran them in his N* with the Holley 950 system. He told me recently that with his tune he had approximately 360 HP at the crank. The reason he sold them to me is that he upgraded to 288 cams. |

|

They ran in a 99 SLS with a 99 STS base tune with just very minor tuning. He had no complants of stalling [This message has been edited by CalibrationEditor (edited 06-02-2011).]

IP: Logged

|

06:48 AM

|

|

CalibrationEditor

Member Posts: 33

From: Rock Hill SC

Registered: Mar 2010

|

| | | quote | Originally posted by fieroguru:

You can't have a meaningful comparison between a stock ground cam and an aftermarket one unless you measure both cams at the same intervals. The .039" of the stock compared to the .050 of the aftermarket ones will almost always show more duration, simply because it is closer to the base circle and GM lets their valves open/close at very slow rates. Also the you really need to compare the cams at .200 to .400 lift ranges to see which has the larger duration.

Here is an example of how lazy and wide the stock cam vs. my aftermarket cam (not an N*, but and LS4). I used a degree wheel and plotted both cams at .006, .025, .050, .075 and every .025 interval from open to peak to close and graphed the relative differences. You will notice that the .006 and .025 values on the stock cam are very, very wide and wider than my aftermarket cam with almost 30+ degrees more duration than at .050.

|

|

Would it help you to know that the 272 cams are regrinds?

IP: Logged

|

06:50 AM

|

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

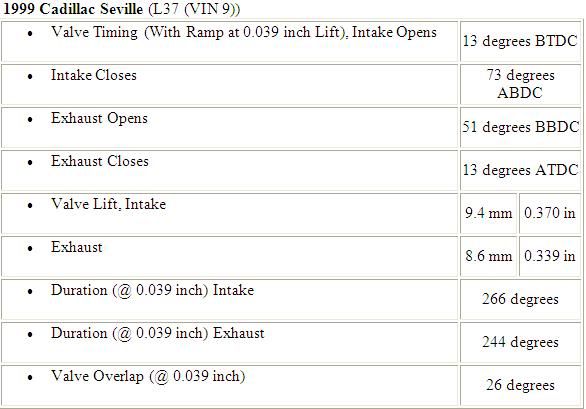

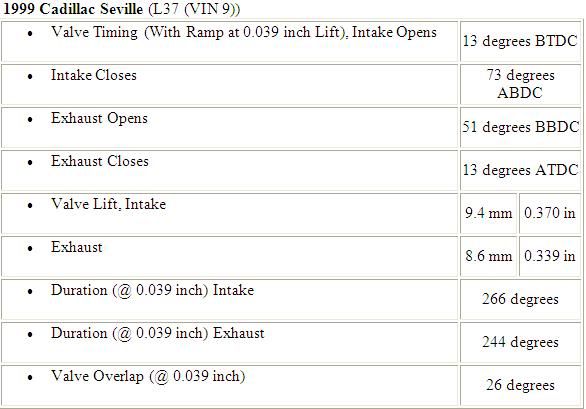

FYI, the LD8 and L37 specs you show here are at 0.0 039" of lift (that's 0.1mm). They are essentially seat to seat duration figures. [This message has been edited by Will (edited 06-02-2011).]

IP: Logged

|

08:15 AM

|

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

did you get a chance to dyno or measure with a G-Tech what the competition cams output over stock?

IP: Logged

|

06:21 PM

|

|

|

Jun 3rd, 2011

|

CalibrationEditor

Member Posts: 33

From: Rock Hill SC

Registered: Mar 2010

|

| | | quote | Originally posted by Will:

FYI, the LD8 and L37 specs you show here are at 0.0039" of lift (that's 0.1mm). They are essentially seat to seat duration figures.

|

|

The CHRFab cams are at .050" and the stock spec are at .039" We are talking about .011". I know this is hard to compare, but the cams are reground OE cams. Its not that hard to see what cams wre used and how they compare. Just look at the timing. Now David's engine only make 14" of vacuum at idle. Really look at how small the cams are. Just look at the overlap and timing for that matter. Then ask your self why 14"

IP: Logged

|

02:26 PM

|

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

| | | quote | Originally posted by CalibrationEditor:

The CHRFab cams are at .050" and the stock spec are at .039"

|

|

The manual quotes the stock duration figures at 0.1mm of lift. This is 0.0 039 inches. | | | quote | Originally posted by CalibrationEditor:

but the cams are reground OE cams. |

|

Well... yeah. Alan has *always* said his cams are reground. [This message has been edited by Will (edited 06-03-2011).]

IP: Logged

|

03:44 PM

|

|

|

Jun 4th, 2011

|

CalibrationEditor

Member Posts: 33

From: Rock Hill SC

Registered: Mar 2010

|

I guess I need to check my math

IP: Logged

|

02:08 PM

|

|

|

Aug 24th, 2011

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

OK. I’ve put about 2000 miles on the 50K engine and the reground 272 cams and started getting some lifter noise.

I pulled the motor to inspect what was going on today and found that the exhaust cam, on the left hand side, had two cam journal caps broken (on the bottom side of the cap). Those two cam journals had loose bolts in them and I think that they worked themselves loose and eventually broke with the cam slamming them. That is what was making what I thought was the lifter noise.

So Northstar brothers, I was just wondering what would cause the cam journal caps to break? Could it be the harder springs and reground cams from CHRF making more push against the journals? My head shop not tightening all the cam cap bolts correctly when they checked and installed the 272 cams?

I’m going to have to find two journal caps I guess. I kinda think that it is not good to use new caps on a used head since there may be variances since they were not line bored together.

What do you think about using blue Lock tite so the bolts can’t back out, get loose and break?

--David

IP: Logged

|

05:08 PM

|

|

|

PFF

System Bot

|

|

|

|

|

Aug 25th, 2011

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

I took the valve cover off the other side and found that on the exhaust cam only, random loose bolts! Why not the intake cam? Interesting. Nothing broken on that side though. Sigh.

IP: Logged

|

03:34 PM

|

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

Sounds like assembly error. Check out McMaster-Carr P/N 7181A21 for a driver that can torque the cam saddle bolts correctly. Always remember that no one cares more about how well your engine runs than you do. [This message has been edited by Will (edited 08-25-2011).]

IP: Logged

|

04:31 PM

|

|

Bloozberry

Member Posts: 7760

From:

Registered: Jan 2009

|

When I rebuilt my Northstar, I found that several of the cam bearing cap-bolts had been torqued beyond their yield point. The pic below shows a new bolt on the left, an over-stretched bolt in the middle, and one that broke on the right. The middle bolt had obviously been over-stretched since it "necked-down" over the first few threads nearest to the unthreaded portion of the bolt shank. Perhaps this is what happened to yours too... have a close look at all of them. Once the bolts are over-stretched, they'll continue to stretch easily under normal engine loads and loosen up.  [This message has been edited by Bloozberry (edited 08-25-2011).]

IP: Logged

|

06:07 PM

|

|

|

Aug 30th, 2011

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

Yes, from now on, I will double check everything coming from a machine shop...everything. After discovering the broken caps, I went back and retorqued each bolt on all the cams and used blue locktite on each bolt after cleaning. I had one bolt break off just like in your picture when removing it. I wasn't hard on it either. It simply broke. I decided to use the cap as a guide and a transfer punch a divit for drilling. Surprisingly the 10.9 graded steel was easy to drill with a cobalt drill bit. The problem was getting out the metal threads as some of the bolts had corroded with the aluminum and wouldn't come out easy. The more I worked that hole, the worse it became...to the point that I thought I should just get another head(the proper thing to do since they are line bored together). I ended up getting most of it out with tools I had to make and old dental tools. For the rest of the debris, I just drove the matter to the bottom of the hole. I used a stud instead of a bolt in that hole. Since I had so much invested in the heads, I thought I'd see how accurate GM was on the line boring of other Northstar heads. I found an 1997 Aurora at the wrecking yard and took everyone of the intake and exhaust cam caps on the same side head. I measured each Aurora cap with plastigage on my cams checking for out of round, alignment and size. I was surprised to find that the caps were very, very, very close to my 4.6 cam caps! I'm impressed that GM could line bore them relatively accurate from different production years for a different Northstar version/application. Perhaps I just got lucky! I guess I get to see how long my cams last this way. So, I'm having spirited fun again. Put 40 miles on it so far and not a lick of lifter noise. I'll take it to work to the University today, on a 60 mile commute, and see if any noise reappears. Now, if I could find an LS1 tuner that can tune to Will's or Zac's Northstar dyno output sheet! [This message has been edited by IXSLR8 (edited 08-30-2011).]

IP: Logged

|

10:51 AM

|

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

| | | quote | Originally posted by Bloozberry:

When I rebuilt my Northstar, I found that several of the cam bearing cap-bolts had been torqued beyond their yield point. The pic below shows a new bolt on the left, an over-stretched bolt in the middle, and one that broke on the right. The middle bolt had obviously been over-stretched since it "necked-down" over the first few threads nearest to the unthreaded portion of the bolt shank. Perhaps this is what happened to yours too... have a close look at all of them. Once the bolts are over-stretched, they'll continue to stretch easily under normal engine loads and loosen up.

http://images.fieroforum.co...am_Bearing_Bolts.jpg

|

|

The bolts are 6mm and only get torqued to about 7 ftlbs. Most shops don't have torque wrenches that go that low. Most mechanics are likely to disregard a low torque figure anyway and do it by "calibrated feel", which obviously is seldom well calibrated. | | | quote | Originally posted by IXSLR8:

Yes, from now on, I will double check everything coming from a machine shop...everything.

The problem was getting out the metal threads as some of the bolts had corroded with the aluminum and wouldn't come out easy. The more I worked that hole, the worse it became...to the point that I thought I should just get another head(the proper thing to do since they are line bored together). I ended up getting most of it out with tools I had to make and old dental tools. For the rest of the debris, I just drove the matter to the bottom of the hole. I used a stud instead of a bolt in that hole.

Now, if I could find an LS1 tuner that can tune to Will's or Zac's Northstar dyno output sheet!

|

|

Zach has headers and (I assume) a reasonable tune. I have a built shortblock and am essentially untuned (still running OBDI LD8 program). Don't get your expectations up too high  Left-hand flute drill bits (they exist!) cut when turned counterclockwise and are excellent for removing the threads of broken bolts from holes. Like I said, no one cares more about your engine running well than you do. Machine shops are paid to cut metal, not turn wrenches. Mechanics are paid to get work out the door quickly to make the most of book labor rates. Neither are good choices to assemble an engine that *YOU* have to live with.

IP: Logged

|

02:49 PM

|

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

My 1996 GM service manual says the cam caps get torqued at 106 inch pounds. That's what I used. I found another GM source that said 5 inch pounds plus 30 degrees plus 30 degrees. Fortunately I have two torque wrenches one for small values and one for the heavier values.

Have to invest in a set of Left-hand flute drill bits!

IP: Logged

|

06:09 PM

|

|

|

Aug 31st, 2011

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

Another 80 miles and no lifter noise.

Came to a stop light where two lanes go into one with a huge new 4x4 next to me. The right side merges and I was on the left side.

The 4x4 floored it and tried to cut me off. Well, he got surprised.

Still no lifter noise.

IP: Logged

|

03:04 PM

|

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

I had a Beretta try to do that once in Pensacola... Same results. He was probably more awestruck than surprised, though. [This message has been edited by Will (edited 08-31-2011).]

IP: Logged

|

03:34 PM

|

|

|

Dec 3rd, 2011

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

Still no noise in the valve train! Still have my SPEC stage 3 clutch. Still don't like the random stalling as a result of the CHRF cams and the LS1/Shelby tune. Time to find some stock VIN 9 cams, I guess...or use my CHRF Commander 950. [This message has been edited by IXSLR8 (edited 12-03-2011).]

IP: Logged

|

12:09 AM

|

|

|

Mar 13th, 2012

|

88GTS

Member Posts: 104

From: North Vancouver, BC Canada

Registered: Oct 2004

|

Anything new on this?

IP: Logged

|

07:13 PM

|

|

|

PFF

System Bot

|

|

IXSLR8

Member Posts: 674

From: Post Falls, ID, USA

Registered: Sep 2004

|

Its been pretty quiet.

Its still quiet with my valve train so its all good.

BUT, my PCM just gave me a code to deal with "crank sensor relearn". So, I have to find a Tech II or someone who has one here in Portland.

Last I heard from AJ is that there were no issues running the LS1 PCM with stock cams on a manual tranny. I've been looking for a set of intake cams for a ViN9 to get my random stall to go away.

Still a blast to drive.

Any news with you, Will, regarding your LS1 PCM tune that you are considering?

IP: Logged

|

11:13 PM

|

|

|

Mar 14th, 2012

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

I've been working ridiculous hours on the most complex satellite our company has ever built that's already suicidally late for the last six and a half months... so not really. Also had to deal with head gasket failure on my daily driver. I am making progress on a very nice streetable catalyzed exhaust for the car so I don't get a noise ticket every other block. [This message has been edited by Will (edited 03-14-2012).]

IP: Logged

|

07:42 AM

|

|