It's been a while since our cruise control worked.

It worked fine, then I had clutch issues where I replaced the master and slave.

Then no worky. I suspected that the switch on the clutch was adjusted wrong.

But adjusting it didn't help.

The fuse was good.

The cable was attached to the throttle body.

So I just let it go and didn't worry about it.

Yesterday I decided to try and fix it.

I tested the switch by the clutch pedal.

Using a multimeter set for continuity (and beep), it would test "open" most of the time and if I wiggled it it would sometimes "close" and beep.

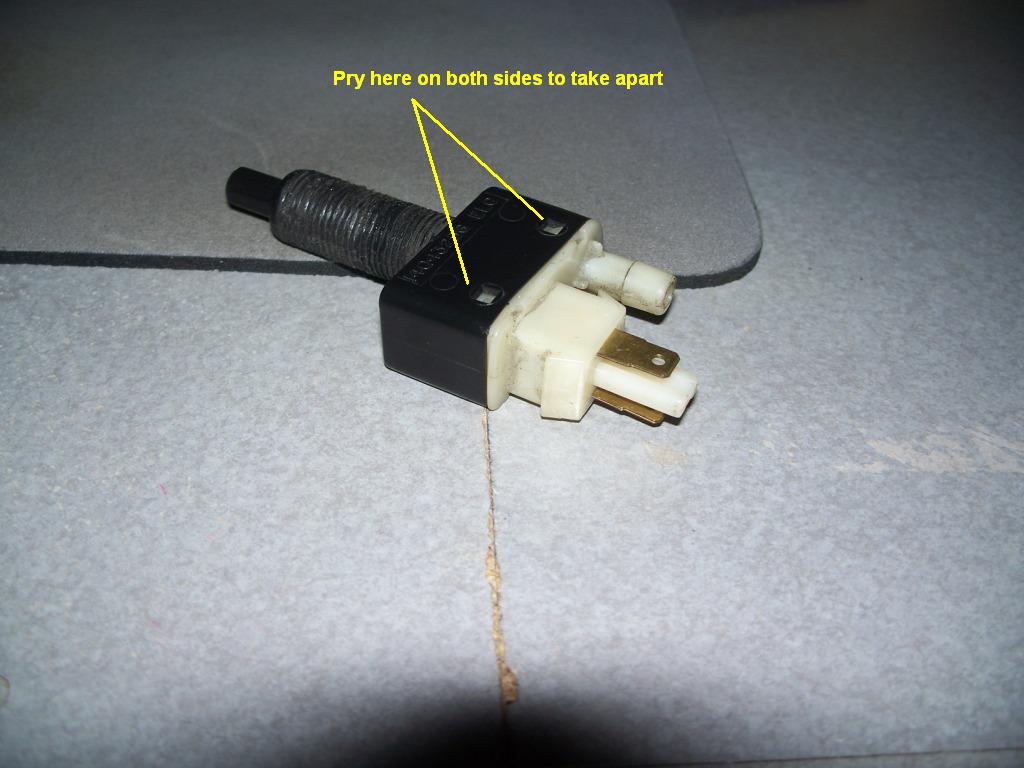

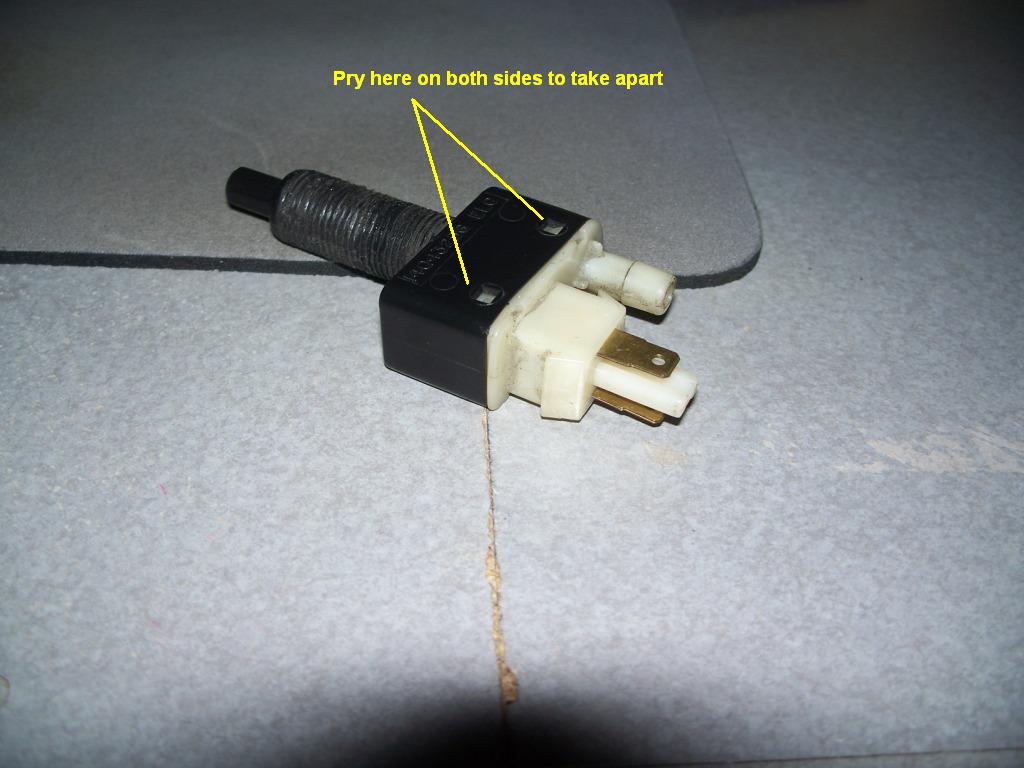

So I removed it, took it apart and wiped all of the old goopy grease off the contacts.

I added new dilectric grease and put it back together.

It now tested good consistantly.

Nope - Still no worky.

I read

the cruise control write up in Ogres Cave. I like pictures so I took a few.

There's a good write up there on how to test the multifunction stalk.

Mine was good. So on to the control module in the engine bay.

Here is how to test the ground, vent valve, engine vacuum, vacuum canister and diaphram. Unless otherwise stated, all tests were performed with the ignition OFF.

First off, a description of the parts involved.

The circled area is where the vacuum hose from the module plugs into the vent valve.

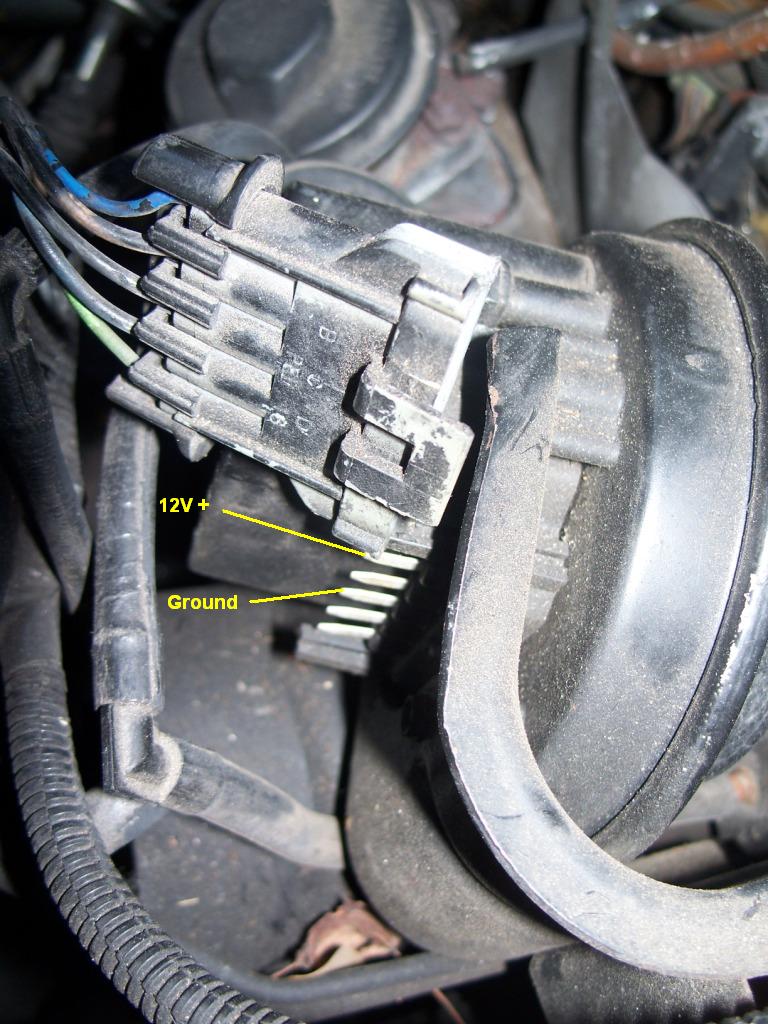

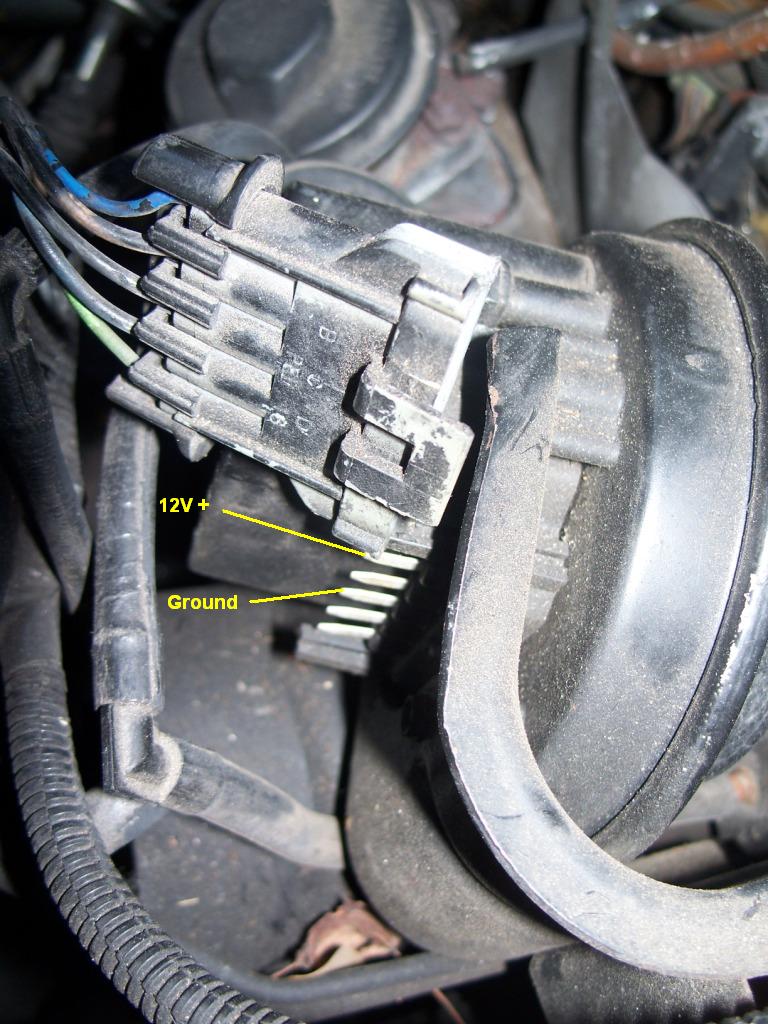

The connector plug here is unplugged. The pin layout is labeled A-E. You can only read the B C D though.

Below the connector, you can see the 5 pins that the plug connects to.

A is at the top. E is at the bottom.

Testing the ground:

Testing the ground:With a multimieter, set for testing continuity, connect one test lead to contact C in the the connector plug and the other to a grounded point on the car.

If the tester doesn't go to zero, you have a bad ground.

Testing the vent valve:If the vent valve is functioning properly, it will seal when contact C on the module (not the plug) is grounded and 12V + is sent to contact A on the module.

When you hotwire the vent valve you should hear a click. If you have a vacuum pump and enough hands you can hotwire the valve and apply vacuum to the top hose.

It should hold the vacuum until you disconnect the power from the contacts.

Testing the vacuum canister:Remove the lower hose from the module. Apply vacuum with a pump. If it holds vacuum, the canister and one-way valve are working.

Testing the engine vacuum:With the car running, disconnect the lower hose from the module. When you do this engine should slow and stumble a little. If it doesn't change, it's probably already running rough. If so, you have a vacuum leak somewhere. Insert the hose onto a vacuum gauge. Then shut the car off. Again, the vacuum should hold until the gauge is removed.

Testing the diaphram:With the car running, disconnect both hoses from the module. Put the lower hose on the upper tube. The lower hose is a smaller diameter so be careful to not split the hose. When you disconnect the lower hose the engine should slow and stumble a little. Put your finger over the end of the hose to stop the vacuum leak. Apply power and ground to pins A & C again. You will see the diaphram start to suck in. Be ready for the RPMs to shoot up when you do this. As soon as you see that the diaphram is pulling in, disconnect the power and ground from A & C. The system will allow the vent valve to open back up and let air in.

While performing these tests, I found that a hose had developed a crack where it plugged into the vent valve. Snipping off the end of the hose and inserting it back onto the vent valve cured my problem and the cruise control works again.