Well... Lets start this one off with a story! I woke up, I did my daily wake up routine. I packed my car for a nice long day out, to band practice and then to a friends house for alcohol and fun. I Got in the car, I try to put it in reverse... it wouldnt go in. It kept feeling like it was hitting the gate, even though the shifter was all the way to the right. I thought it was odd. I know my cables are stiff but, if it doesnt go in, I can easily slap it in gear if I wiggle the shifter gate to gate.

I finally got it into reverse, went and got gas, and left for band practice. Felt funny shifting though... I was on the highway and I wiggled the shifter... it felt like it was in neutral. It would slop back and forth, way too easily. I knew then something broke. I went back to my house, and took off the shifter panel to access the shifter. I looked at the mechanism and noticed... I cracked it! The select pin was still perfect, it was the shifter itself that cracked.

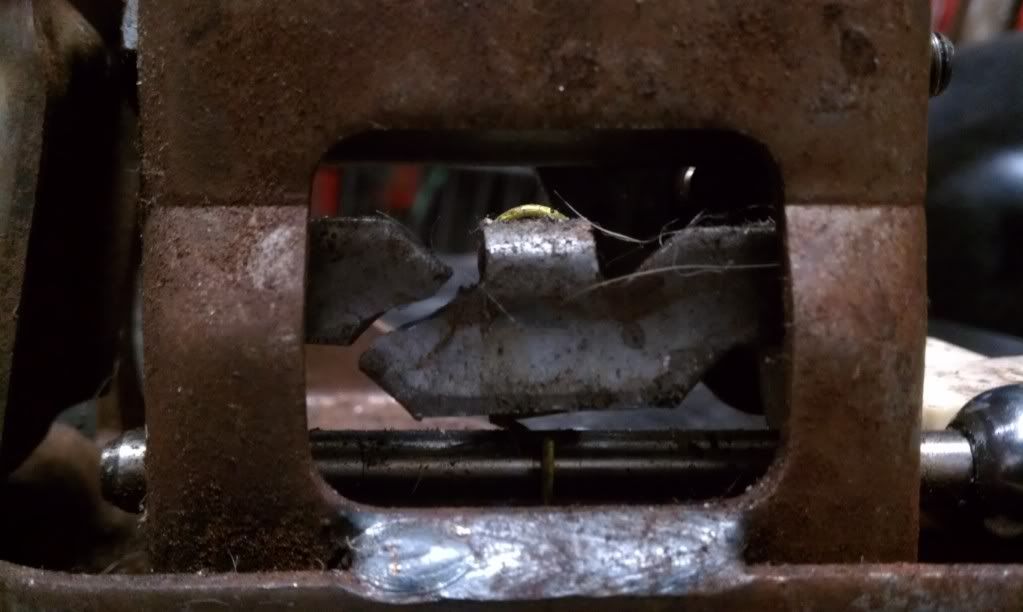

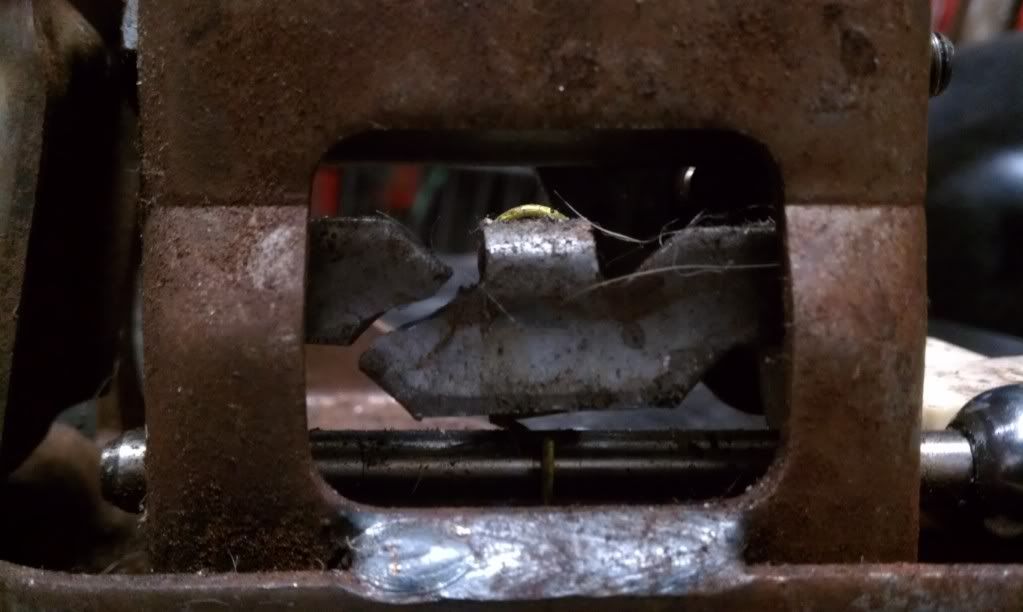

Now I had to run into my work, and find out what happened. I ripped apart my car with my tools at work, Pulled the center console out and ripped out the shifter, this is what I had found. Any one else ever seen a getrag shifter break like this?

Well anyway, that is what I found. This is what the interior looked like at this time

I took the shifter and started to disassemble it

First removing the shifter lever by removing the E clip, then I ground the rivet off of the little bracket that blocks the bolt to remove the shifter select assembly. I also removed the E clip that hold on the select lever on the select pin.

Then I removed the Select assembly, Removing the bolt, and tweaking it to one side, to pull the select ball off to avoid the select pin. Then I pulled it out... and this is what I got

As you can see, it broke quite well. As I noticed, there is not much weld that holds the sleeve onto the select assembly. it appears to have broken right next to the weld, and the weld was not properly penetrated into the base metal of the bracket, so it easily cracked off due to weld being brittle. I rewelded everything, after tweaking the broken bit to fit tighter to the sleeve. I welded it around the sleeve on the broken side completely, giving it time to cool off, and bouncing back and forth around it to prevent tweaking from the heat. I also welded the small bit that broke that holds the select ball rod in place, as straight as I could. Since the other sleeve might break off, I also strengthened its weld surface area with a couple more support welds. I did not get a GOOD picture of it out, as I forgot to get a picture of it while it was out... but here is the pictures I got of the repaired select assembly

I also decided to try an idea I had... I always hated the Getrag's tall shifter. So I had this idea to chop out the angled portion of the shifter and make it a short throw shifter. To do this, I put tape around the shifter rod. Again I forgot to take pictures of this... But the tape set lines to cut along, with margin of error. I used a cut-off wheel and cut the shifter rod first at the top, then at the base. After that, I took both parts to a grinder and flattened the rough cut edges to be perfectly flat. I still had a sharp edge, and a weld on this edge would not be strong. I chamfered the edge of the rod on both sides to provide some bite, then welded it with the welder cranked high and hot, slowly going around the shifter in sections to make it tight and strong. This is the outcome after some cleaning to get rid of sharp and unclean edges:

After a quick reassembly... I had this

Compare to the previous picture of the assembled assembly, the shifter is MUCH shorter. Here is the shifter installed in the vehicle... NOTE: Don't mind the Jameson on the passenger floor... it was for later, as this was an emergency repair mid day, between band practice and happy drinking time with some friends :P.

And that is it. Not the best write up, but that is how I repaired my shifter. I believe this is an uncommon break.... Has anyone else seen it?

[This message has been edited by Racing_Master (edited 11-27-2011).]