|

|

|

|

Turning the fiero into a racing machine... by ryan.hess

| Started on | : 12-27-2004 04:39 PM |

| Replies | : 278 |

| Last post by | : ryan.hess on 05-07-2006 10:43 AM |

|

|

|

|

Jan 6th, 2005

|

gusshotrod

Member Posts: 729

From: Goshen, IN.

Registered: Nov 2004

|

Todd, Will, Paul: Check your E-mail.

IP: Logged

|

09:37 PM

|

|

|

Jan 7th, 2005

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

| | | quote | Originally posted by toddshotrods:

Isn't the the overall diameter of your current tire size an inch larger than stock? I have the same size (225/50-16) on my car right now and it is an inch bigger than the 215/60-14's or the 225/50-15's I had on it previously.If so, your ultimate combination will be at the original ride height. Down two inches from lowering knuckles, back up one inch from pro-dive elimination shims, up another inch from increased overall tire diameter (as compared to stock). My car is lowered about three inches right now and the wheels fit beautifully inside the stock wells IMO. Can barely squeeze a finger between the top of the front tire and the fender lip.  Of course, I don't have stock inner fenders to worry about, and eventually the bodywork will be all custom to fit around the new suspension. Of course, I don't have stock inner fenders to worry about, and eventually the bodywork will be all custom to fit around the new suspension.

|

|

Aren't stockers on the fast backs 215/60-15's? Or are they 205's? Either way, they're approx the same height as 225/50-16's. I'd like the tires a little taller.

I should end up about 1" lower than stock, which is about where I want to be.

You can barely get a finger between the top of the tire and fender, but what about the front and rear of the tire? How big is the gap between the front edge of your tire and the front edge of your wheel house, or the corresponding gap at the rear edge of your tire? I don't like having to creep over speed bumps and gutters. A friend of mine has a '95 Eagle Talon that's lowered with a very low FMIC... he doesn't go fast over anything but perfectly smooth pavement. I don't want to have to worry about that.

IP: Logged

|

12:39 AM

|

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

I've never had a GT so I didn't realize they had larger diameter tires from the factory. The disk that had the pics of my car with the fenders on is corrupted, and I used the fenders to set up a mock front end for my dad to do a custom front fascia for his Fiero. I also had tubular mounts for the hood and fenders up front that have since been removed - sooo, I can't take a new one right now. As far as I can remember, the gap was probably bigger in front of and behind the tire, but that doesn't bother me so much. Actually, I kind of like the "slammed" look on some vehicles. The pinched gap on top makes it clear that the vehicle is lowered. I also don't mind creeping over speed bumps, etc, because the car is just an occasional use toy. In any event, when this car finally hits the road again it will have custom bodywork with fender openings made for the stance and tire size so the gap will be consistent. I wasn't saying there was anything wrong with your setup, or ride height, it was just a interesting observation. My dad's car is at the stock ride height, where he intends to keep it, and he simply wants to add bigger tires to fill the gap. I think it will look nice. What the heck is "FMIC"?!?!  edited for typos

------------------

Todd Perkins - the member formerly known as "perkidelic"

todd's hot rods [This message has been edited by toddshotrods (edited 01-07-2005).]

IP: Logged

|

01:35 AM

|

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

Thanks gusshotrod! ------------------ Todd Perkins - the member formerly known as "perkidelic" todd's hot rods[This message has been edited by toddshotrods (edited 01-07-2005).]

IP: Logged

|

01:46 AM

|

|

gusshotrod

Member Posts: 729

From: Goshen, IN.

Registered: Nov 2004

|

I am the man.

IP: Logged

|

01:52 AM

|

|

Kohburn

Member Posts: 7349

From: Oriental, NC

Registered: Jul 2003

|

damn I feel left out now :P yeah I was going to point out that the fieros with 14" wheels were smaller diameter than the 15" rimmed fieros.. my current plan is to make custom knuckles, raise the upper ball joint, and raise the rear pivot of the lower control arm to atleast reduce the pro-dive..

IP: Logged

|

07:16 AM

|

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

FMIC = front mount intercooler (as opposed to the stock DSM side mount) He's pushing a touch over 400 HP on race gas. Stock engine, big injectors, FMIC, T3/T4, 2.5" turbo back, DSMLink, GM MAF, MAFT and a couple other things

IP: Logged

|

09:26 AM

|

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

| | | quote | Originally posted by R Runner:

...I will also run the simulation of the stock suspension if someone has time to take the measurements... |

|

I almost forgot about this. How precise do the measurements need to be? I have a complete (minus shocks and springs) front suspension off the car. I don't have machinist's quality measuring tools though. If a measuring tape and cheap caliper will do the job just let me know what you need. ------------------

Todd Perkins - the member formerly known as "perkidelic"

todd's hot rods

IP: Logged

|

08:17 PM

|

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

.jpg) Will, is there any reason that these can't be machined to accept a shallower bearing/hub assembly, to reduce scrub? I was going to go to Autozone tomorrow to measure the depth but for example: 1982 Cadillac Eldorado

$ 82.99 - rear bearing assembly (Timken pt # 513009)

109.99 - front bearing assembly (Timken pt #513013) I was thinking that maybe it would be possible to use the rear bearing on the front of the Fiero, and vice versa in back with custom or different knuckles. ------------------

Todd Perkins - the member formerly known as "perkidelic"

todd's hot rods

IP: Logged

|

08:34 PM

|

|

gusshotrod

Member Posts: 729

From: Goshen, IN.

Registered: Nov 2004

|

Kohburn: Ck you PM's.

IP: Logged

|

08:40 PM

|

|

Kohburn

Member Posts: 7349

From: Oriental, NC

Registered: Jul 2003

|

| | | quote | | Originally posted by toddshotrods:

I almost forgot about this. How precise do the measurements need to be? I have a complete (minus shocks and springs) front suspension off the car. I don't have machinist's quality measuring tools though.

If a measuring tape and cheap caliper will do the job just let me know what you need. |

|

to the nearest 1/16 is probably the best anyone could ask

IP: Logged

|

09:03 PM

|

|

|

PFF

System Bot

|

|

Kohburn

Member Posts: 7349

From: Oriental, NC

Registered: Jul 2003

|

| | | quote | Originally posted by toddshotrods:

Will, is there any reason that these can't be machined to accept a shallower bearing/hub assembly, to reduce scrub? I was going to go to Autozone tomorrow to measure the depth but for example:1982 Cadillac Eldorado

$ 82.99 - rear bearing assembly (Timken pt # 513009)

109.99 - front bearing assembly (Timken pt #513013) I was thinking that maybe it would be possible to use the rear bearing on the front of the Fiero, and vice versa in back with custom or different knuckles. |

|

I was thinking machine it to accept bolt on hubs like the 88front or the pre-88 rear (with a compression bolt setup inplace of a halveshaft end) but if you can find a better option that'd be great

IP: Logged

|

09:05 PM

|

|

|

Jan 8th, 2005

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

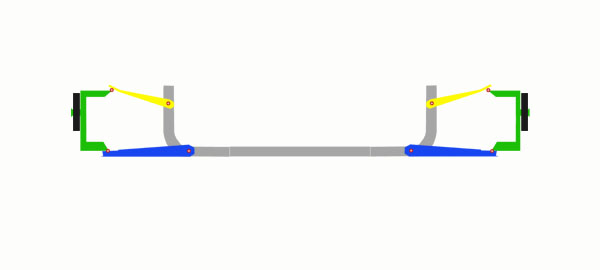

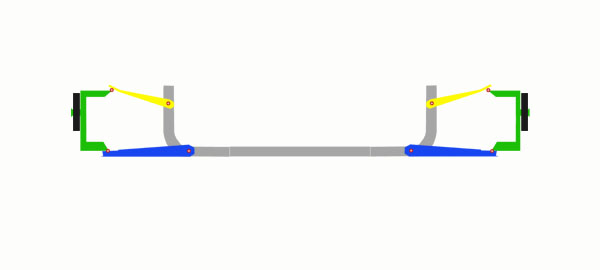

Nearest 1/16th I can do. I will get the measurements and put them on this image. What else will be needed? It might look a little goofy right now because I just wanted to get it set up.

IP: Logged

|

12:34 AM

|

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

| | | quote | | Originally posted by toddshotrods: .jpg)

Will, is there any reason that these can't be machined to accept a shallower bearing/hub assembly, to reduce scrub? I was going to go to Autozone tomorrow to measure the depth but for example:

1982 Cadillac Eldorado

$ 82.99 - rear bearing assembly (Timken pt # 513009)

109.99 - front bearing assembly (Timken pt #513013) I was thinking that maybe it would be possible to use the rear bearing on the front of the Fiero, and vice versa in back with custom or different knuckles. |

|

That setup was based on G/F-body wheel bearings. The spindle has already been shortened relative to those cars in order for the bearings to package properly in the hubs. The way to less offset would be via bolt in hubs.

Speaking of which... I need to do a little more research... The C5 front hubs, C5 rear hubs and '98+ Grand Prix front hubs all use the same bearing seat. I'm sure there's a 5x115 non-drive axle bearing that uses the same seat as well. That family of bearings are the units to use as far as I'm concerned.

IP: Logged

|

01:52 AM

|

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

| | | quote | Originally posted by Will:

...The way to less offset would be via bolt in hubs... |

|

That's what I was getting at. I am pretty sure the Eldo's front bearing is a bolt-in hub assembly. Not sure about the rear but for that price it should be a non-drive hub assembly to match the front. | | | quote | Originally posted by Will:

...The C5 front hubs, C5 rear hubs and '98+ Grand Prix front hubs all use the same bearing seat...That family of bearings are the units to use as far as I'm concerned. |

|

That might work out for the 115mm pattern but I don't think many people are going to spring for C5 hubs. Even in my blow the budget to the wind planning I try to find a way around them. GM Parts Direct

$434.14 - (7470569)C5 front bearing/hub assembly ($361.78 + 72.36 shp)

438.41 - (7470571)C5 rear bearing/hub assembly ($365.41 + 73.08 shp) ------------------

Todd Perkins - the member formerly known as "perkidelic"

todd's hot rods [This message has been edited by toddshotrods (edited 01-08-2005).]

IP: Logged

|

03:10 AM

|

|

Joe Torma

Member Posts: 3485

From: Hillsborough, NJ USA

Registered: Jul 2001

|

When I took my crossmember out 2 months ago, I took dimensions and came up with this sketch. It should be pretty accurate...though the top pivot doesn't take into account the caster. I wanted to see what happens to the track and camber of the car so it's the center of the angled tube. Don't know if it will help(I do believe this is the good side of my crossmember  )...here you go )...here you go

Todd, can you confirm the upper control arm pivot location?

This is a good thread  [This message has been edited by Joe Torma (edited 01-08-2005).]

IP: Logged

|

04:26 AM

|

|

R Runner

Member Posts: 3699

From: Scottsville, KY

Registered: Feb 2003

|

Here are some of the things that are needed. It is intended to be 3D software. It's a little old (2001) but should do the trick. Physics doesn't change right!?!? I need X (from car center), Y (height from Ground or ref. point), and Z (position rearward from a plane in front fo the car). For each side: Upper Ball Joint

Upper frame piviot Front

Upper frame piviot Rear

Lower Ball Joint

Lower frame piviot Front

Lower frame piviot Rear

Tie rod on rack

Tie rod on Spindle

Shock connection upper

Shock connection lower I'll need more info as the analysis gets more involved. I will need to be at home on a work day to get that code and the chances of that happening are .... well....... slim. Greg..... I bet you have some time in this one.  Thank you again. Thank you again. Paul

IP: Logged

|

07:21 AM

|

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

The upper control arm pivot is the main thing on my drawing that I figured is goofy. I will check all the measurements I can and readjust the drawing to match. I am not sure I can get all the measurements you need Paul. The front suspension I am taking measurements from is off the car. My car is not running right now and I can't move it around. I can't take measurements from it where it is either. I had a company that was going to do the complete suspension design for my car, and started taking measurements for them. Before we started working on it, I decided to look elsewhere because I didn't like how long it took to get replies from them. We were going to trade services for the project, and I am glad I figured it out before I committed to any work for them, or they did any actual work for me. I think it would have been a loooonnnggggg frustrating deal. Not saying it is a bad company, just not the right one for me. I was taking these measurements to see what could be done with the aluminum Street Dreams knuckles. I was planning on a new crossmember with altered pick-up points, and whatever was needed in tubular control arms. We didn't need the measurements from the car because it was going to be pretty much from scratch. We were basically designing the suspension for good geometry and designing the crossmember to properly locate it in the car. Other changes were going to be an LCA that pivoted solely off the crossmember (instead of the rear pivot being on the chassis) and coilover shocks. The Street Dreams knuckle-based design was an experiment, and I really planned to use the C5 knuckles. I think I am still going that (C5) route but would also like to help develop a suspension that will fit in otherwise unmodified Fieros. Last time I checked (GM Parts Direct) the C5 knuckles were $108.74 with shipping. Find a good deal on bearing/hub assemblies and I have a great start for not a lot of $$$. The thing I don't get is why work with the stock crossmember? If you're gonna spend $800 for new knuckles, $??? for new wheels with the correct offset, and hundreds more on tubular arms, why not go a little further and get a crossmember that puts the pivot points where they really should be? Would look real nice with the new cradle out back  The reason more companies won't do this is the development time is so high, and the sales projections so low, that they will likely never even break even. We're doing this because we want to go fast around corners. We "profit" when it works. Then the rest of the community can benefit from it, for pennies on the dollar (compared to what a business would have to charge to be successful with it). The reason more companies won't do this is the development time is so high, and the sales projections so low, that they will likely never even break even. We're doing this because we want to go fast around corners. We "profit" when it works. Then the rest of the community can benefit from it, for pennies on the dollar (compared to what a business would have to charge to be successful with it). I am proposing grassroots design and manufacturing here. We develop two or three suspension systems and make it possible for Fiero enthusiasts to take matters into their own hands from there. Sort of like open source software. You can download the design and have at it, or you can find someone to produce it for you for a fee. The only thing we ask is that people share the advancements they make along the way. Crossmember

There are at least couple companies that can spit out the mandrel-bent rectangular tube main section. The price should be pretty reasonable because all they are doing is cutting a piece of tubing, sticking it in the CNC machine, trimming it, and shipping it. Single unit price shouldn't even be too bad. Develop a simple CAD program for the jig. You can build the stuff yourself, have a shop build it, or get a bunch of buddies together for group purchases and building - welder of the bunch gets his free  , etc. , etc. Control Arms

Maybe it would be possible to use control arms from a company like Stock Car Products. Dirt cheap compared to most "dedicated" designs. Again, CAD programs available for download for more ambitious types. I could go on but hopefully I made my point. I think we could develop a really nice suspension setup that could be done relatively cheap - if we stick to the "open source" enthusiast plan. I would be willing to host all of the important details and the CAD programs on my site. That would provide a free, consistent, location for people to always find it. ------------------

Todd Perkins - the member formerly known as "perkidelic"

todd's hot rods

IP: Logged

|

11:32 AM

|

|

Jncomutt

Member Posts: 8902

From: Charlotte, NC

Registered: Apr 2001

|

Will You have a PM

IP: Logged

|

01:27 PM

|

|

ryan.hess

Member Posts: 20784

From: Orlando, FL

Registered: Dec 2002

|

| | | quote | Originally posted by Joe Torma:

This is a good thread

|

|

No kidding. It's a little hard to follow for a suspension tuning n00b like me with all these "pressure centers" and "scrub radius" and what not... But I think I'm learning

IP: Logged

|

02:05 PM

|

|

gusshotrod

Member Posts: 729

From: Goshen, IN.

Registered: Nov 2004

|

Todd: I agree with almost everything in your post. A fabricated crossmember will allow less expensive components to be used to achieve correct geometry. Two things I'm not sure off. I'm sure the crossmember can be built without the mandrel bent tubing which would make it easier for those that want to build their own. Also I would like to see some specs on the C5 spindles. The C4 spindles I have have quite a bit of scrub and I don't know if the C5 is any better. Also the steering arm on the C4 spindle is cast with the spindle and would slow the steering rate if the stock rack is used, don't know about the C5. An aftermarket rack would solve this problem and allow different ratios and the option of power steering. Maybe there is a less expensive spindle out there with bolt-on steering arms. Might want to look at mustang II components as they are pretty generic on street rods. Anyway, if everyone involved can agree on a design, I would like to offer to build a SMALL run of these for those involved in the design. Cost will be materials + shipping.

IP: Logged

|

03:13 PM

|

|

|

PFF

System Bot

|

|

|

|

Kohburn

Member Posts: 7349

From: Oriental, NC

Registered: Jul 2003

|

| | | quote | Originally posted by toddshotrods:

Crossmember

There are at least couple companies that can spit out the mandrel-bent rectangular tube main section. The price should be pretty reasonable because all they are doing is cutting a piece of tubing, sticking it in the CNC machine, trimming it, and shipping it. Single unit price shouldn't even be too bad. Develop a simple CAD program for the jig. You can build the stuff yourself, have a shop build it, or get a bunch of buddies together for group purchases and building - welder of the bunch gets his free  , etc. , etc.Control Arms

Maybe it would be possible to use control arms from a company like Stock Car Products. Dirt cheap compared to most "dedicated" designs. Again, CAD programs available for download for more ambitious types. I could go on but hopefully I made my point. I think we could develop a really nice suspension setup that could be done relatively cheap - if we stick to the "open source" enthusiast plan. I would be willing to host all of the important details and the CAD programs on my site. That would provide a free, consistent, location for people to always find it. |

|

the control arm Idea may work - would have to look at what was available - as for the crossmember the hardest part I see to that is getting aligning the strearing rack mounts.. I would use welded sections not a bent peice.. but you are righ that it may be easier to make a new crossmember than to modify the existing one.. with drawings of a welded setup other fiero enthusiats could just make their own.. a very nice DIY.. I plan to use no special offset rim, just a standard 45mm offset than most aftermarkets are available in - and design innexpensive bolt together knuckles.. a cross member that could be easily made from measuring cutting and welding a few peices of steel would be a nice improvement.. [This message has been edited by Kohburn (edited 01-08-2005).]

IP: Logged

|

08:21 PM

|

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

I think an easy way to make the cross member would be to use a piece of large rectangular tubing transversely, with tabs for the bolts that go vertically into the frame rails. Welded onto the ends of this would be vertical pieces of channel with the open end outward. The LCA inner pivots would be a pieces of round tubing or pipe welded into the rectangular tubing, while multiple holes could be drilled through the channel for UCA inner pivot and possibly coil over upper mounts. Fitting the three horizontal bolts into the sides of the frame rails might be a bit of a challenge, but the end of the channel migh be boxed to bolt to the factory brackets... I think we have enough ideas here to make a sufficiently adjustable knuckle to satisfy pretty much anyone. The one issue left would be quick and dirty control arms. I think that there are enough pieces readily available in the Mustang II aftermarket to be worth considering. They also do similar things with LCA's as we're discussing. The MII originally had a lateral arm with a tension/compression strut going rearward... very similar in concept to the early Fiero LCA. The MII crowd has developed ways of readily adapting an A-arm in place of the original equipment.

IP: Logged

|

09:48 PM

|

|

Will

Member Posts: 14269

From: Where you least expect me

Registered: Jun 2000

|

| | | quote | Originally posted by toddshotrods:

That might work out for the 115mm pattern but I don't think many people are going to spring for C5 hubs. Even in my blow the budget to the wind planning I try to find a way around them.GM Parts Direct

$434.14 - (7470569)C5 front bearing/hub assembly ($361.78 + 72.36 shp)

438.41 - (7470571)C5 rear bearing/hub assembly ($365.41 + 73.08 shp) |

|

What I was pointing out was that once the car has knuckles with the proper bearing seat, it would just be a matter of changing hubs (and possibly outer CV's) to go to the 5x4.75" bolt pattern and have greater wheel availability. The "LS1" brake rotors (12" used on '98+ F- and W-bodies) have a bolt pattern that accomodates both 5x115 and 5x4.75, so a car with those rotors wouldn't even need to change brakes.

IP: Logged

|

09:52 PM

|

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

| | | quote | Originally posted by gusshotrod:

...I'm sure the crossmember can be built without the mandrel bent tubing |

|

It can be. I thought about it and realized that I just like the look of a mandrel bent piece. There is no reason it can't be fabricated/welded. | | | quote | Originally posted by gusshotrod:

...Also I would like to see some specs on the C5 spindles...the steering arm on the C4 spindle is cast with the spindle and would slow the steering rate if the stock rack is used, don't know about the C5. An aftermarket rack would solve this problem and allow different ratios and the option of power steering. Maybe there is a less expensive spindle out there with bolt-on steering arms. Might want to look at mustang II components as they are pretty generic on street rods. |

|

The C5 spindle is just what I plan to use. I think it is probably too tall for people who don't want to do a lot of cutting and welding. The UCA pick-up points would likely be top of the factory front frame rails, which means the inner fenders would have to be removed and probably a whole lot of other work. C5 knuckles also have the steering arm cast in. On first-gen Camaro C5 suspension packages they usually cut the factory arm off and provide a bolt-on steering arm. I believe the main reason is to lower it because the Vette's rack is mounted much higher. Probably also to get the desired ratio. They use some aftermarket rack. | | | quote | Originally posted by gusshotrod:

Maybe there is a less expensive spindle out there with bolt-on steering arms. Might want to look at mustang II components as they are pretty generic on street rods. |

|

I am sure with some research we could find a pre-existing knuckle that would work. I don't have to have C5 knuckles on my car - that's just what I have been planning on, so I mention them alot. | | | quote | Originally posted by gusshotrod:

Anyway, if everyone involved can agree on a design, I would like to offer to build a SMALL run of these for those involved in the design. Cost will be materials + shipping. |

|

Sounds tasty! I hope we come up with something that I will want on my car now  I am so curious to see what kind of numbers come out of this! Not rushing anyone - just expressing my enthusiasm again.

I made it to Autozone to check out the Eldo bearing/hubs. They didn't have the rear part in stock but I checked out the front (driven wheels).

A C4 Vette bearing for comparison:

.jpg)

I forgot to take my caliper but here is a twenty-five cent pocket tape measure/forty-year-old eyeball approximation: 1.875" - wheel mounting surface to hub mounting surface (fairly accurate)

4.625" - three-bolt hub bolt pattern diameter

These two are where the hub mounts in the knuckle:

3.1875-3.25" - small diameter

3.5625-3.625" - large diameter

I forgot to check the depth of this area. I would like to see what the rear bearing/hub looks like to see if it would be a good choice for a front bearing/hub. If it is this shallow it would make it easy to deal with the scrub issue. ------------------

Todd Perkins - the member formerly known as "perkidelic"

todd's hot rods

IP: Logged

|

10:07 PM

|

|

gusshotrod

Member Posts: 729

From: Goshen, IN.

Registered: Nov 2004

|

Todd: I measured the C4 rear hub and got the same measurements that you did. Looks like these are interchangable. I paid $110 each for these new. [This message has been edited by gusshotrod (edited 01-08-2005).]

IP: Logged

|

10:27 PM

|

|

gusshotrod

Member Posts: 729

From: Goshen, IN.

Registered: Nov 2004

|

C4 front bearing: Bolt pattern 2 3/8 x 3 1/8 Diameter of locating ring 2.825 Distance from hub face to spindle face 2.718

IP: Logged

|

11:06 PM

|

|

|

Jan 9th, 2005

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

| | | quote | Originally posted by Will:

What I was pointing out was that once the car has knuckles with the proper bearing seat, it would just be a matter of changing hubs (and possibly outer CV's) to go to the 5x4.75" bolt pattern and have greater wheel availability. The "LS1" brake rotors (12" used on '98+ F- and W-bodies) have a bolt pattern that accomodates both 5x115 and 5x4.75, so a car with those rotors wouldn't even need to change brakes. |

|

I gotcha. Are there any 115mm FWD hubs that have the same dimensions as a C4 hub? That would make things really nice because the price is right for the 4.75" pattern. Or could CNC concentric rings be made to adapt the hub with the larger pattern. I would not be concerned with a ring that is machined properly and sandwiched between the hub and knuckle. It can't come out. | | | quote | Originally posted by Will:

...The one issue left would be quick and dirty control arms. I think that there are enough pieces readily available in the Mustang II aftermarket to be worth considering. They also do similar things with LCA's as we're discussing. The MII originally had a lateral arm with a tension/compression strut going rearward... very similar in concept to the early Fiero LCA. The MII crowd has developed ways of readily adapting an A-arm in place of the original equipment. |

|

The price is definitely right on the MII components. That is also where my thoughts on mounting the LCA solely to the crossmember came from. If the lengths are right for our app it would be great. Or, maybe one of the companies can accommodate our needs for a nominal fee. There is also a large selection of race-proven hardware for them. | | | quote | Originally posted by Will:

I think we have enough ideas here to make a sufficiently adjustable knuckle to satisfy pretty much anyone. |

|

Think it's possible to do this for anywhere near a pre-existing price? One thing I like is that it would be aluminum. The three main facts that kept me focused on the C5 knuckle - lightweight aluminum, fully engineered for performance apps, relatively cheap. [This message has been edited by toddshotrods (edited 01-09-2005).]

IP: Logged

|

12:48 AM

|

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

| | | quote | Originally posted by gusshotrod:

Todd: I measured the C4 rear hub and got the same measurements that you did. Looks like these are interchangable.

I paid $110 each for these new. |

|

That's the same price Autozone has for the Eldo bearing. The measurements are the same, the price is the same, they look the same... Autozone.com doesn't list a part number for the C4 Timken bearing though. The Eldo part is 513013 what's yours? Where did you get a C4 bearing that cheap? Lowest price I found was about $150. Personally, I would rather run the drive wheel bearing in the front, with a special bolt to keep it together. I like the shallow depth, as it allows longer arms and less scrub. As I said before though, I will help develop a more universal application first. I'll get mine  Will would you mind posting the C5/W-body hub dimensions?

IP: Logged

|

01:11 AM

|

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

| | | quote | Originally posted by Kohburn:

...hardest part I see to that is getting aligning the strearing rack mounts... |

|

.jpg) I made mounts something like this when I was building the Pro Street Fiero. Now that I think about it rectangular tubing would probably be better in place of the round tube stand. Now that we're on the subject, are we designing this setup to use the OEM Fiero rack or setting the LCA pick-up points from the beginning to work with a power rack? To me, it makes sense to design for a fast ratio power rack from the beginning. ------------------

Todd Perkins - the member formerly known as "perkidelic"

todd's hot rods

IP: Logged

|

11:53 AM

|

|

gusshotrod

Member Posts: 729

From: Goshen, IN.

Registered: Nov 2004

|

Todd: Same part number on the C4 bearing! I got mine from Eklers Corvette. When I built my crossmember I used a Sweet rack. The ends of the rack are threaded and you can screw on any length extension you need. Bump steer can be corrected by using washers between the rack and rack mount. The other issue is the weather seal to the interior. I made a plate that sandwiched under the rack and had a ring that sealed around the input to the rack and allowed the rubber sealing tube around the stock steering shaft a place to mount. The pass-thru hole in the floor has to be moved but that was easy and still cleared pedals. For those that don't know, the Sweet rack is available non-powered or powered with an external servo and is avaiable in a range of ratios. It's also dead simple, bullitproof, and easily repairable. There's usually a few on Ebay for under $100. New price for manual is around $325. [This message has been edited by gusshotrod (edited 01-09-2005).]

IP: Logged

|

02:51 PM

|

|

|

PFF

System Bot

|

|

gusshotrod

Member Posts: 729

From: Goshen, IN.

Registered: Nov 2004

|

Question: What type of bushings should be used? I like Heims with Ultraseals. Some might prefer something less aggressive. Lets decide this as it would make sourcing components easier. [This message has been edited by gusshotrod (edited 01-09-2005).]

IP: Logged

|

02:58 PM

|

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

Autozone isn't too smart. They actually carry the C4 bearing but don't list it as an available part number?! Maybe the experienced guys in the stores know... Are you referring to the control arm bushings or the tie rod ends, or both? How about setting some goals before we start chasing down parts? If we determine what we are trying to accomplish, combined with the existing "concrete" facts we can develop a virtual system that will give us the hard numbers we need when looking for those "quick and dirty" parts. For instance, the UCA's are going to be located in the upright ends of the crossmember, on the outsides of the main frame rails, and they can only be located so high. So there are boundaries then on planes X & Y. That's what I call "concrete" facts. If we take the shallowest knuckle/hub combination that we can develop for a reasonable cost - along with the longest UCA that will fit in the available space we can begin to build on it. We just need to establish what type of handling charactersistics we want the produce. Then we can adjust the locations and sizes until the number are as close as possible to our goals. ------------------

Todd Perkins - the member formerly known as "perkidelic"

todd's hot rods

IP: Logged

|

08:50 PM

|

|

|

Jan 10th, 2005

|

Kohburn

Member Posts: 7349

From: Oriental, NC

Registered: Jul 2003

|

| | | quote | | Originally posted by toddshotrods: Personally, I would rather run the drive wheel bearing in the front, with a special bolt to keep it together. I like the shallow depth, as it allows longer arms and less scrub. As I said before though, I will help develop a more universal application first. I'll get mine  Will would you mind posting the C5/W-body hub dimensions? |

|

thats what I was thinking - like stock fiero rears, but more heavy duty.. what is it.. the pontiac 6000 hubs?

IP: Logged

|

06:46 AM

|

|

|

Jan 12th, 2005

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

What happened, everyone went on vacation at the same time?  I'm still working on getting the stock dimensions. I have also finally gotten back to designing my system. I think I will be using the C5 knuckles up front, with custom tubular arms. I have the the stock data for the C5 and it looks like I will be able to adapt this to my chassis without any serious problems. Remember, I don't have the factory inner fenders to restrict me, and am willing to cut and weld as necessary to accomplish my goals. I have a friend who will be working with me to tweak the pick-up points, control arm dimensions, etc. We're gonna be working back and forth in Pro Trends' Suspension Analyzer (same one Paul has). I have the demo right now and plan to get the real deal so I can finish the design. I think I found the shop that will fabricate my arms, crossmember, cradle, etc. If any of you guys follow NASCAR you may have heard the name Doug Blaney before. He is about fifteen minutes from me. A guy who used to work for him (and I think still does special projects for him) has his own fab shop now, so I visited him yesterday. I like what I saw (owner, workmanship, shop). He's also friends with the guy/shop that will be doing my cage so it keeps the "family feel" going. If you're wondering why I am subcontracting so much of this instead of doing it myself - I am a pretty decent fabricator and welder (MIG) but these guys are experienced professionals. My goals are real supercar performance (including the 200mph top end) and I want to live to tell about the experience! What a ride! I started chasing this dream in the fall of '96!!! However that saying goes about the "journey" being the most valuable part of the experience is sooooo true! I haved learned so much, met so many great people, and had so much fun! I hope the car lives up to the experience I had in developing it  ------------------

Todd Perkins - the member formerly known as "perkidelic"

todd's hot rods [This message has been edited by toddshotrods (edited 01-12-2005).]

IP: Logged

|

11:47 AM

|

|

gusshotrod

Member Posts: 729

From: Goshen, IN.

Registered: Nov 2004

|

Some info I tracked town: C4 spindles: 75 mm positive scrub radius on 9.5 inch, 38 mm offset rim C5 spindles: 0 scrub on 9.5 inch, 55 mm ofset rim In addition, the C5 spindle has the upper ball joint inverted, effectivly lowing the spindle height and making it more adaptable to the fiero. [This message has been edited by gusshotrod (edited 01-13-2005).]

IP: Logged

|

04:13 PM

|

|

Crow

Member Posts: 328

From: Antioch, IL

Registered: Mar 2004

|

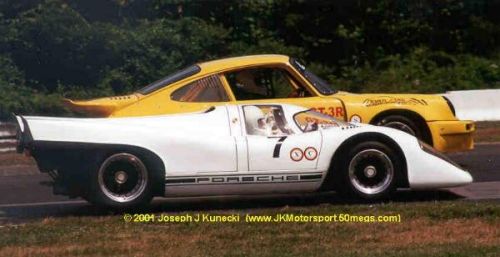

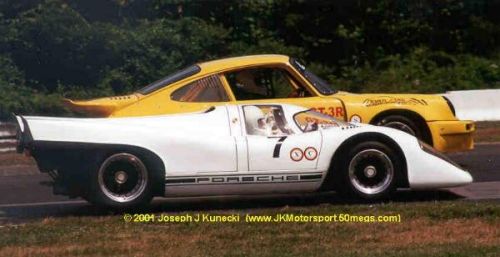

| | | quote | | Originally posted by toddshotrods:

Original

Penske/Donohue

|

|

How many people here know what this car is? This thing is a monster. Love those Can Am cars!

IP: Logged

|

08:35 PM

|

|

toddshotrods

Member Posts: 1177

From: Columbus, OH, USA

Registered: Aug 2004

|

Wow! 75mm?!? The specs from Suspension Analyzer have .36 inches positive scrub radius (2001 Corvette). The ball joint height is still 12.625", a considerable difference from the approximate 8-inches for the Fiero. I have to do some measuring this week but I am guessing the UCA pick-up point is going to be somewhere over the main frame rails, which would mean removing the steel inner fenders at the very least. If the track is narrowed, and the pickup points are moved in substantially, the master cylinder could be in the way. These are just some of the hurdles that may have to be dealt with to use these knuckles on a factory space frame. Since you have a full chassis car, and I will have custom bodywork, the choice is easy. UCA effective length is 8.25". LCA effective length is 16". The upper arms are much shorter than I expected. Gusshotrod, "you've got (e)mail"... ------------------

Todd Perkins - the member formerly known as "perkidelic"

todd's hot rods

IP: Logged

|

09:06 PM

|

|

gusshotrod

Member Posts: 729

From: Goshen, IN.

Registered: Nov 2004

|

A-arm lengths on the bolt in crossmember I built were 17 1/2 lower and 9 1/4 upper. [This message has been edited by gusshotrod (edited 01-13-2005).]

IP: Logged

|

10:56 PM

|

|

|

Jan 18th, 2005

|

Dough19

Member Posts: 661

From: Peoria, IL

Registered: Dec 2001

|

bump come on smart guys.......... I want a Fiero supercar to build

IP: Logged

|

09:44 PM

|

|

Of course, I don't have stock inner fenders to worry about, and eventually the bodywork will be all custom to fit around the new suspension.

Of course, I don't have stock inner fenders to worry about, and eventually the bodywork will be all custom to fit around the new suspension.

.jpg)

)...here you go

)...here you go

Thank you again.

Thank you again. , etc.

, etc.

.jpg)

.jpg)