Over the years I have redone the headliners in all of my Fieros, and I found that more than half of the time the headliner was broken, especially if it was a sunroof car. After a while I started fixing them in favor of replacing them. It has been successful for me now on several cars. There may be other ways to repair the headliner, and probably better ways too, but this is what I have done with success. So if you want to fix your broken headliner and don't know another way, this can help.

Without further ado, pictures and instructions:

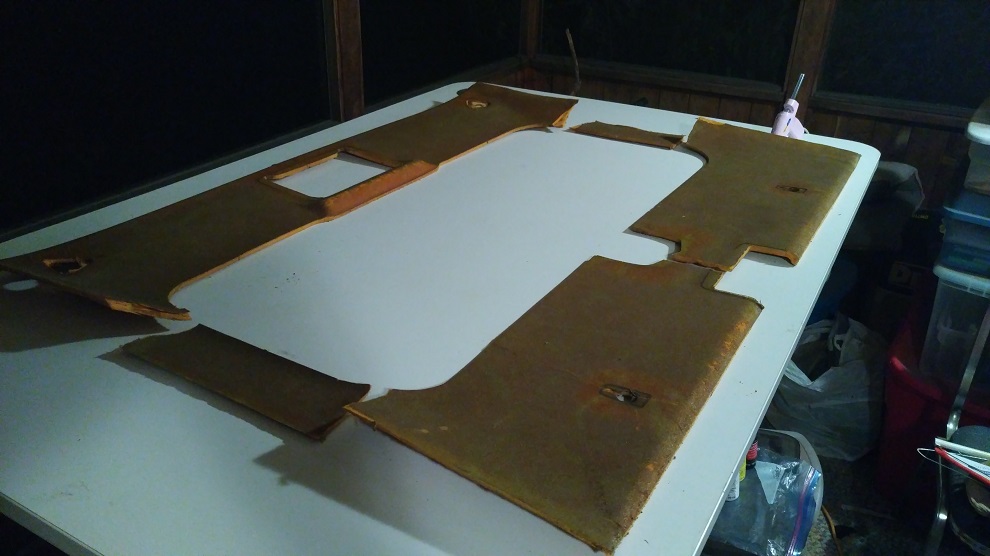

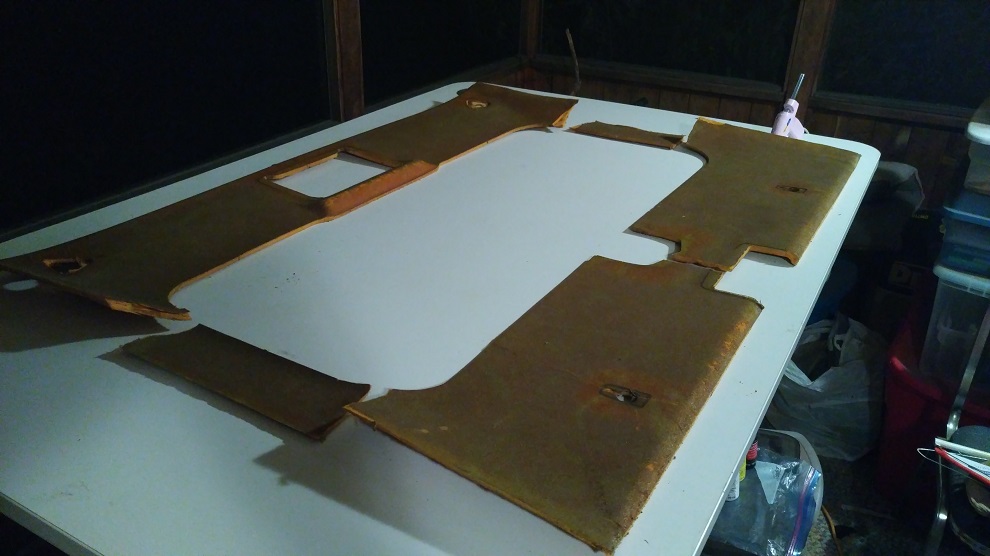

The original headliner, broken, sagging and faded.

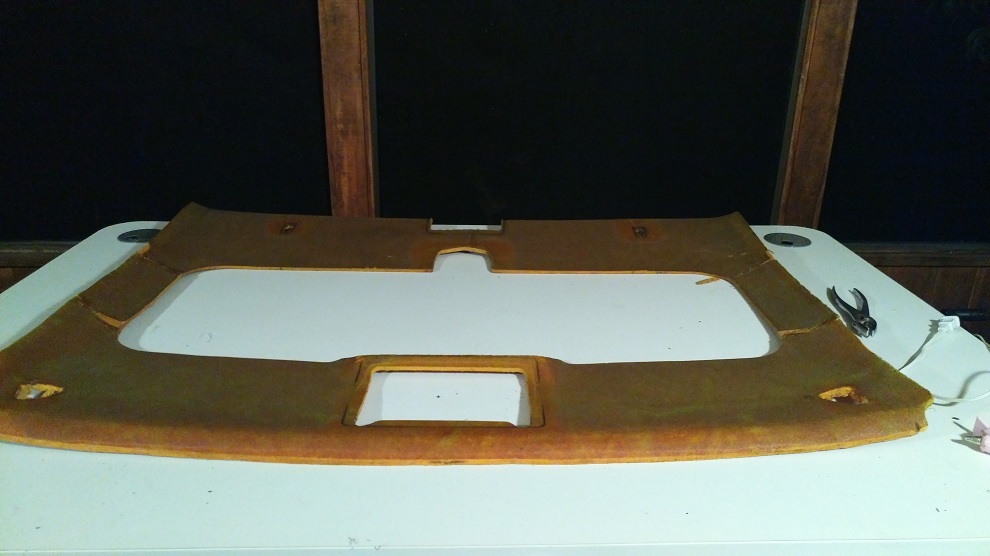

After pulling off the old fabric. We can see the headliner is broken in 5 pieces. It also has a big crack ready to break in another spot.

To get rid off all the old remains of what was once foam backing and glue I use a dish sponge. The rough side is rough enough to remove the old gunk, yet soft enough not to tear the headliner. If the sponge doesn't get it off, its probably not going to come off without ripping something. Then the soft side is really good for brushing off the finer dust.

You can see in this shot how well the sponge works. Compare the right to the left. Notice the final condition remains as a gritty texture. That is fine, but there should be nothing loose or soft left.

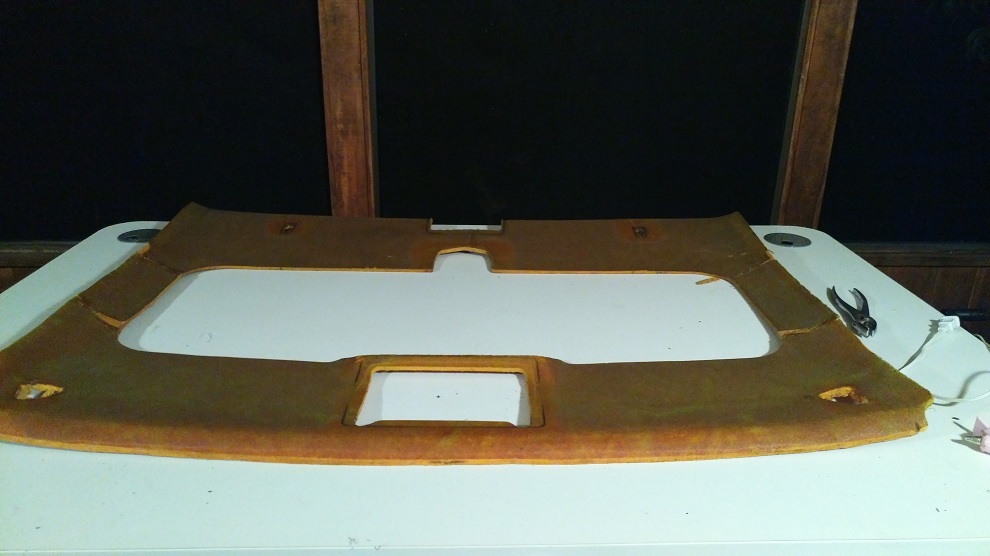

After completing the cleaning process, here are the 5 parts ready for repair.

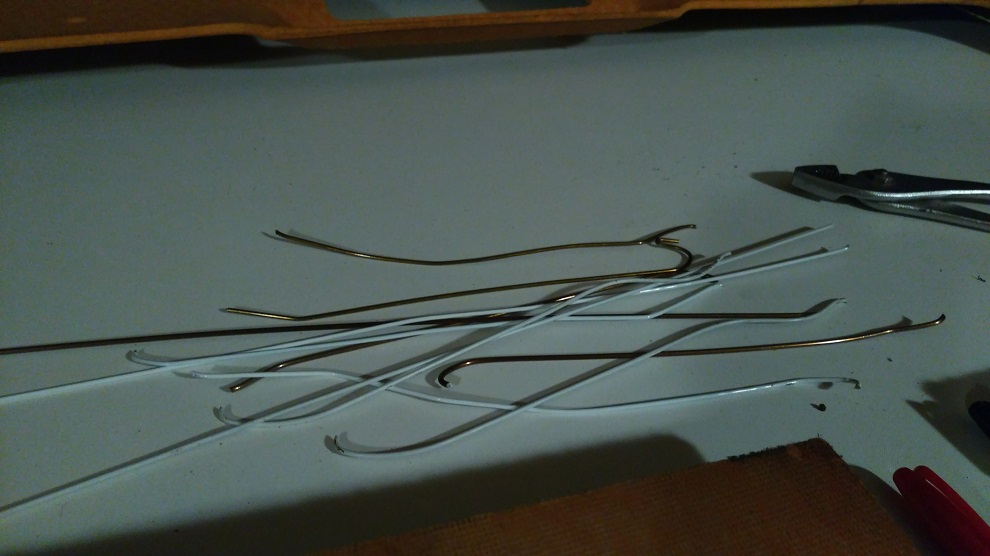

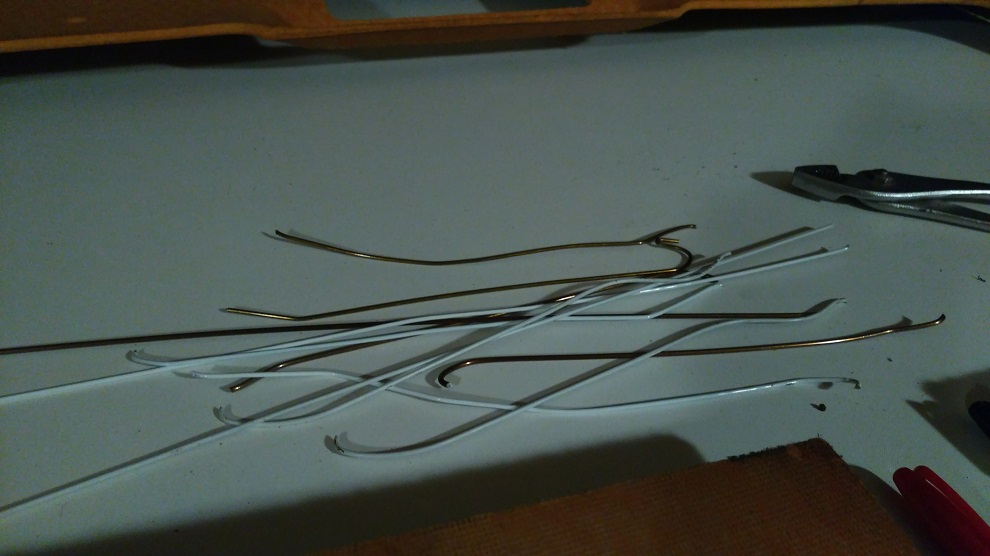

To do the repair work I use old metal clothes hangers cut into pieces, hot glue gun, and card stock or construction paper.

First put glue on both sides of the broken edge and stick together as it is supposed to be. Then use the wire hanger pieces for strength.

I find gluing in a circular motion increases the strength. Also don't be shy with the glue.

I put two pieces of the metal for each break. More couldn't hurt though.

Here is the headliner with all of the breaks fixed and the crack strengthened.

Flipping over the headliner reveals some uneven or inconsistent surfaces at the break points. I try to fill in any gaps with hot glue. Try to make it as smooth as possible. Doesn't have to be perfect, but you don't want mountains or peaks that jut out.

Then take your spray glue (which ever type you will use to secure your new fabric) and spray some over the break spots. Cut the card stock and spray some glue on it too.

Then put them together. This smooths out the inconsistencies and can add addition strength. You can still notice a slight bump at the crack. It will not be noticeable if you are using foam backed fabric. If you use thinner fabric, then I would suggest using a thin cardboard, like the back of a pad of paper. Then sand the edges (before attaching to headliner) to taper its width down.

And now the repaired headliner ready for fabric!

If you want my method of applying the fabric, then continue reading.

I use the Permatex headliner and carpet glue. It is very strong and durable. It does not leave much room for error though. Once it sticks, it will hold. Headliner will tear before the glue pulls and fabric will rip before the glue gives. So don't mess up haha! 3M has a more foregiving glue, but I found its durability over the years was shorter. So I take my chance.

The Permatex is available in most auto stores, you can't miss its bright can.

First I lay the material over the headliner and cut it to a closer dimension. I usually order a yard and a half. Its enough to do the headliner and sun visors.

Then pull back a section, spray glue on the headliner and the fabric, wait a few minutes for it to get tacky and press together. I find starting from the back easiest since its nice and flat. I like to work from the middle out to the edges. This is especially useful on headliners without sunroof. Work along the middle hump, then go into the dips one at a time working outward. Sunroof headliners are much easier to apply the fabric. Haven't done a t-top yet.

Continuing on down the headliner from back to front.

Once all gluing is done, I flip it over, cut the openings and glue the edges over the back. I forgot to get a picture of the back. You want about an inch of fabric folded around the back of the headliner and glue it down. This makes all the edges nice and strong and look good too.

Next, on to installation. sunroof less cars are done at installation. The hard work off fabric application pays off haha.

Since this one is a sunroof I will continue. Here it is installed. I don't cut the middle until after putting it in. it can be cut ahead of time as well I would assume.

Then cut around the edge about 2 inches. I then stick the rubber on, not worrying about the extra fabric. I let it pop out the top of the rubber. This is just for test fitting. The rubber surround does a nice job marking the line to cut along for a perfect fit. It makes 2 lines. One shows the bottom side where it enters the cavity. The other shows the top where it exits. If you cut along the top line it will result in a nice fit with no excess. You can see the inner line here since I just cat along the outer line.

Once sized, I reapply the rubber surround, by pulling the headliner fabric above the rubber and then pushing the rubber in the cavity. It will pull the fabric in and give a nice tight finish.

The rubber now all in place, looking fro the top.

And the finished product from the inside

And that's it!!

From broken old headliner to nice strong fuzzy new one!

------------------

All things work together for good to those who love the Lord. -Romans 8:28