During my engine rebuild, I found that the hole in my charcoal canister mount is "stripped".

The factory sheetmetal screw no longer bites in the hole:

Hence I have decided to drill (don't know how large yet) out these holes and use U-nuts instead.

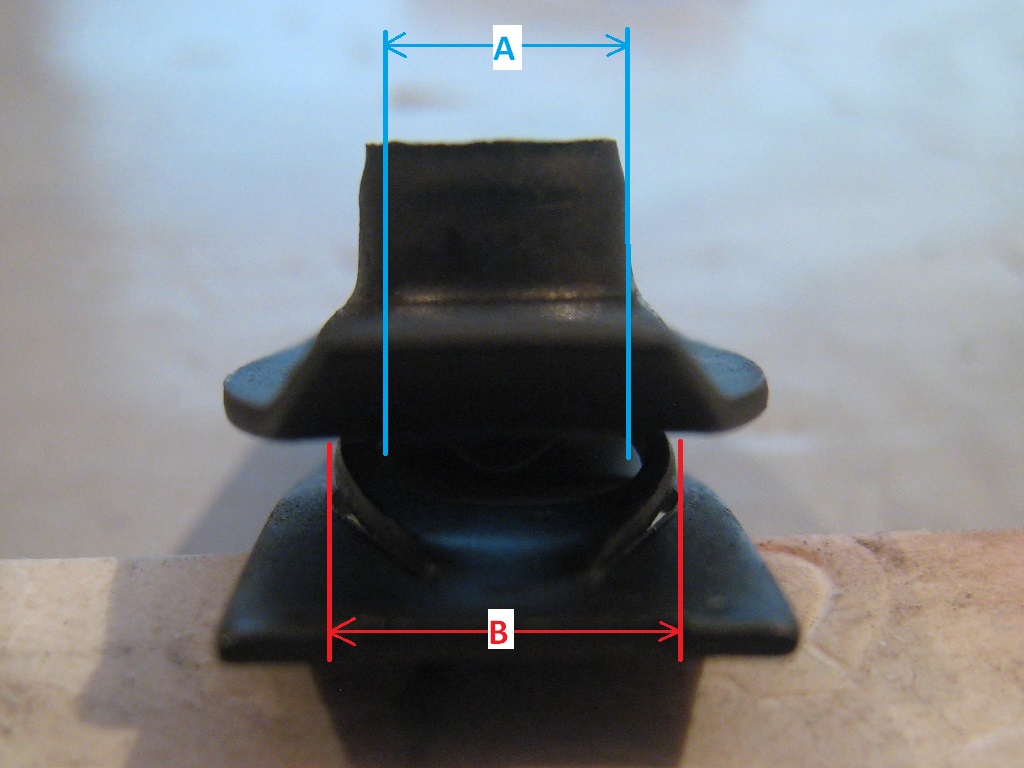

I picked up this package from Canadian Tire:

They have a spring-loaded tang.

I want to know what is the proper hole diameter (in the panel) for use with U-nuts of this style.

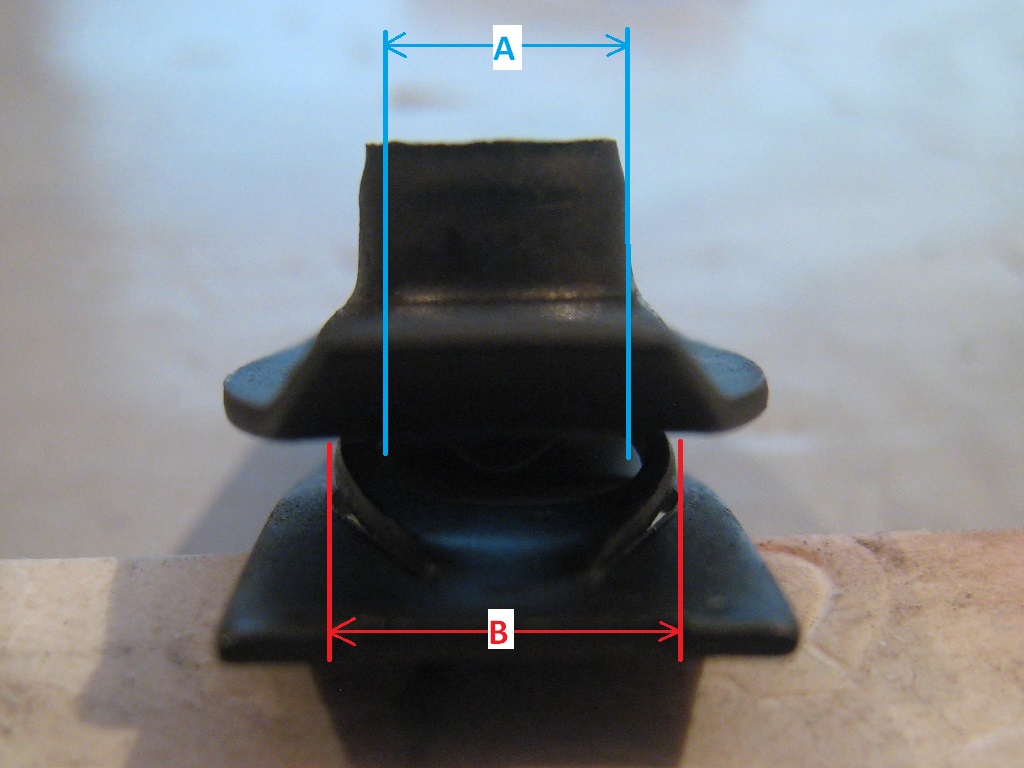

I am presently imagining two possible hole sizes, which I have named A and B:

A:

Large enough to allow the screw to pass through, but the tang does not fall into the hole. The tang maintains a constant squeeze on the panel.

B:

Large enough for the tang to snap into the hole... this kind of "clips" the U-nut into place, making it semi-captive.

Which of these methods is the correct one?