Alright, so I think I'll purchase a spool of 0.032" stainless wire, and I'll twist it using the vise-grips I already have.

I decided to count the pixels on the eBay photo of the screws, and the drilled holes measure about 0.057", so the standard wire should fit.

| | | quote | Originally posted by fieroguru:

Leaving the bolt loose, will allow it to rock in the nut and it will eventually wear down and snap off.

If there is a metal sleeve inside the rubber bushing, you can fully tighten the bolt (so it won't back out) and still allow the rubber bushing to do its job.

You can also spend about $15 and get some rubber isolation mounts that are designed to do exactly what you are looking for: This is a crappy pic, but there is a stud on 1 side, nut on the other, and only rubber connects the two ends.

|

|

Yeah, I'm not so hot on the idea of leaving screws not too tight. I may just try really large washers; I may be able to get decent torque this way without destroying the rubber bushings.

If that's not enough, I'll press in metal sleeves, slightly shorter than the rubber. The local hobby shop has thin brass tubing that would do the trick.

Even if the bolts are tight enough not to require safety wire, I've already ordered the drilled bolts, so I'd like to take the opportunity to add a new shop skill to my repertoire... which is one of the reasons I have a project car.

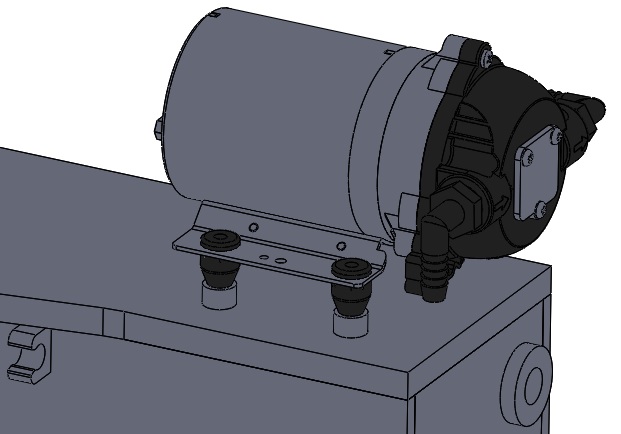

Shock mounts would work too, but I'd have to modify the pump mounting base, which is something I'd prefer to avoid (not a hard requirement though). When the pump bites the dust, I want replacement to be a drop-in affair.

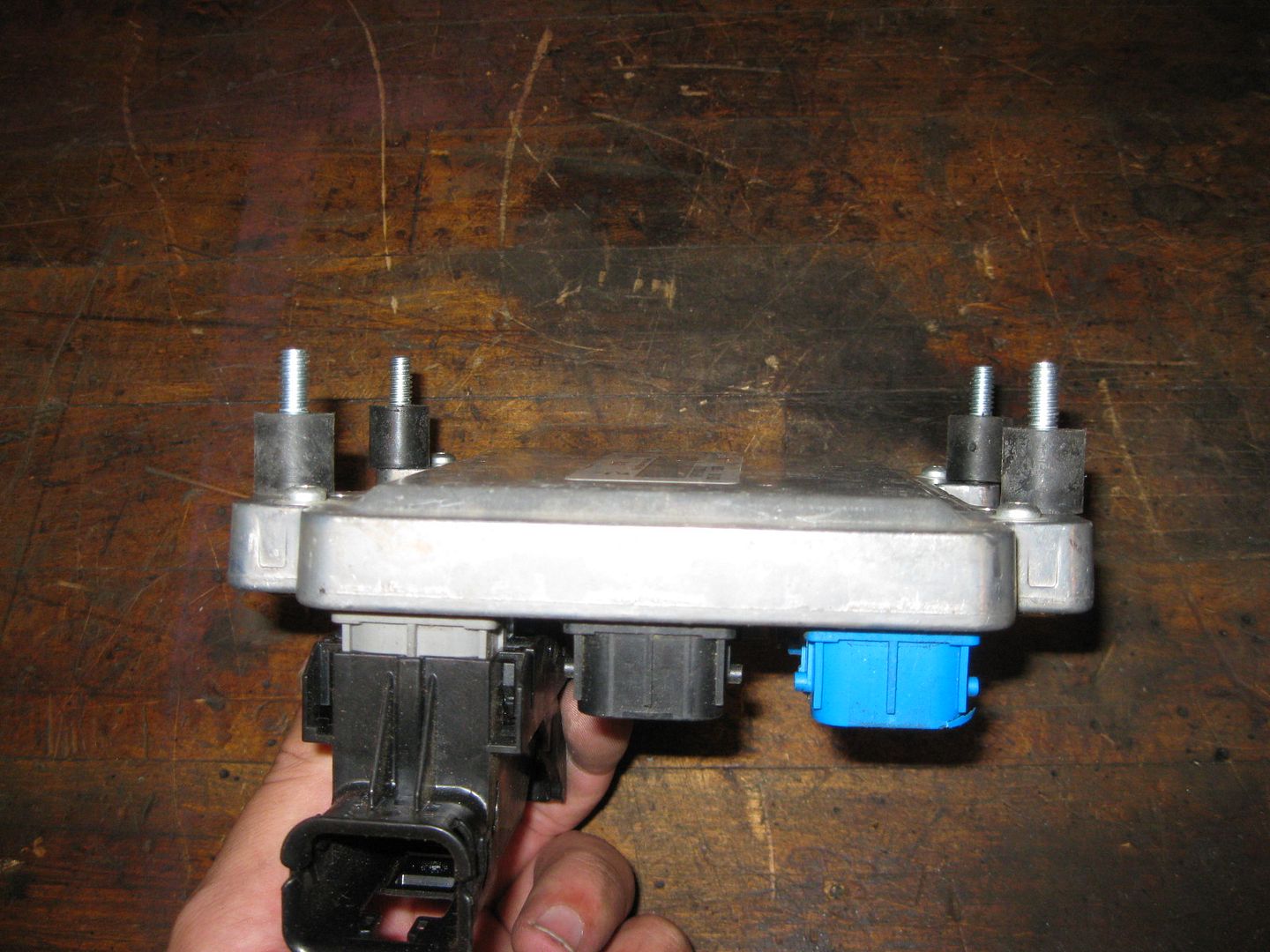

Strangely, Holley doesn't tell you how to mount their (relabeled Shurflo) pump:

https://www.holley.com/prod...onents/parts/557-100In their photo, there are some normal-looking bolts, but I'm not sure how developed that solution is...

| | | quote | Originally posted by Blacktree:

What are you bolting the pump to? Are there going to be nuts on the other side? If so, why nut use lock-nuts? |

|

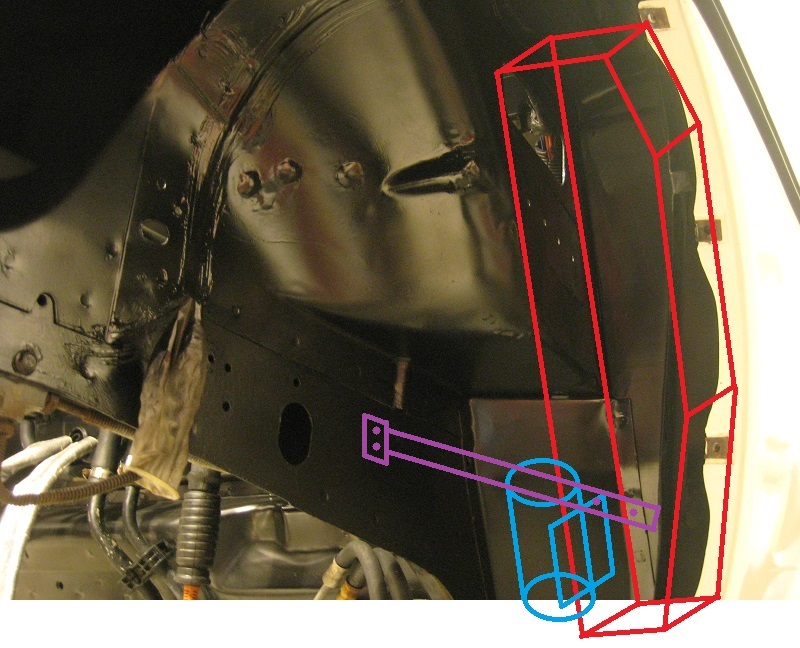

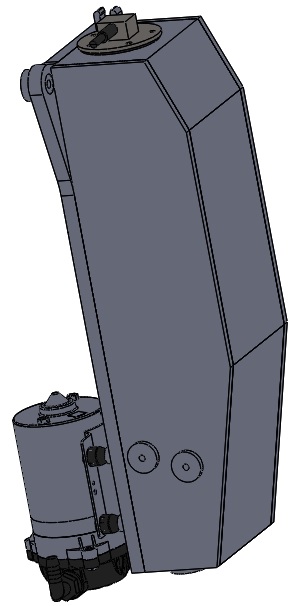

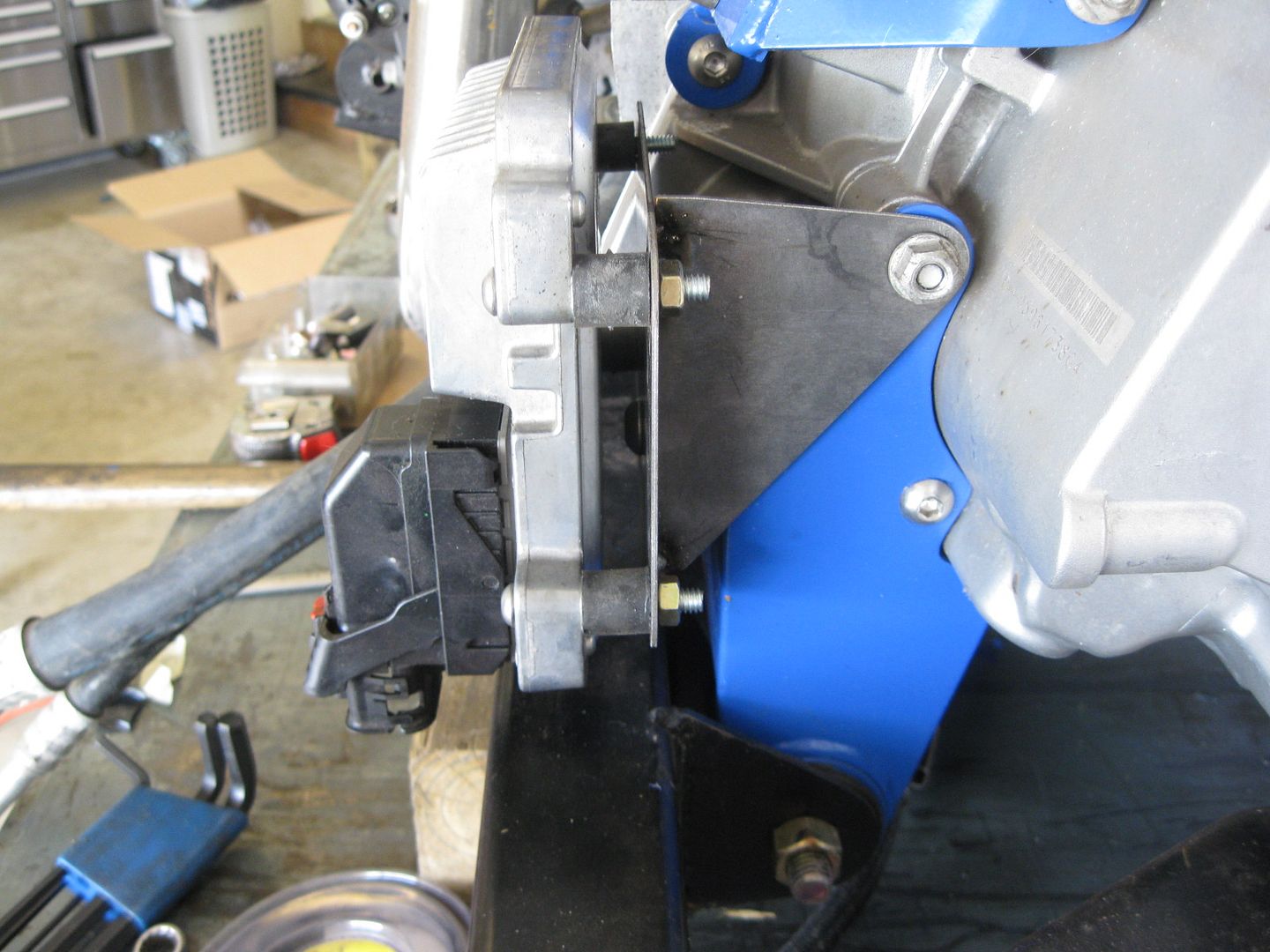

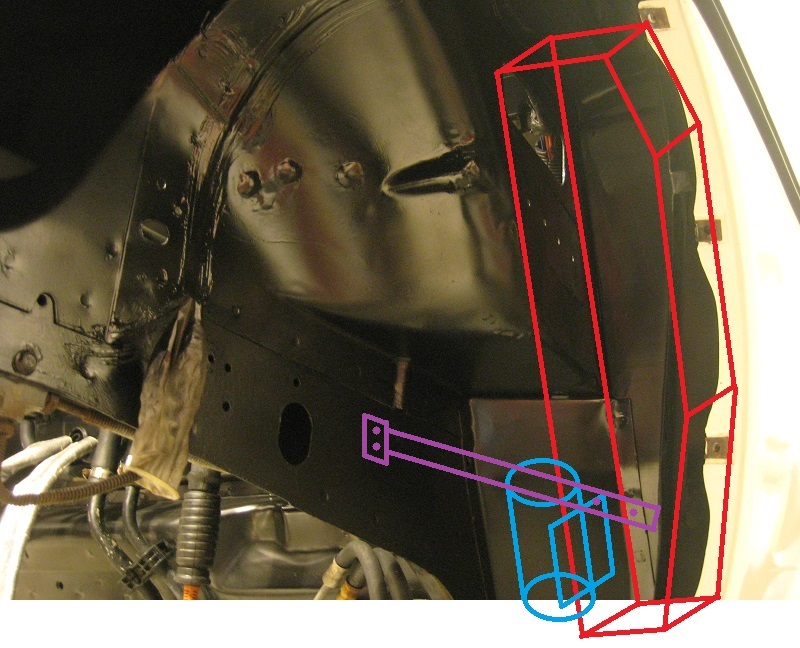

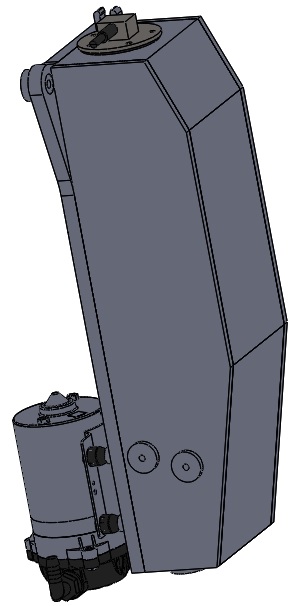

The pump is mounted to the water tank. The water tank is made of 3/8" and 1/2" rigid PVC foam (for weight savings vs solid) panels, cemented together.

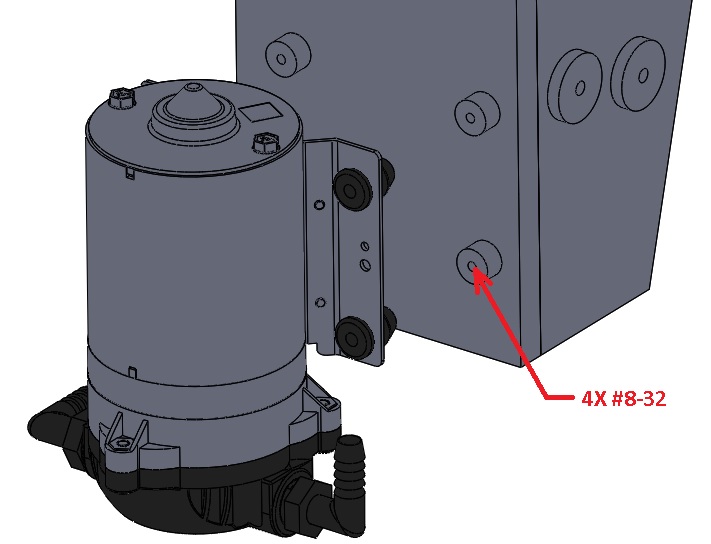

PVC foam can strip "easily" if screwed into directly, so wherever there are fittings or bolts going into the tank, I made some threaded bushings made of solid PVC, cemented in place.

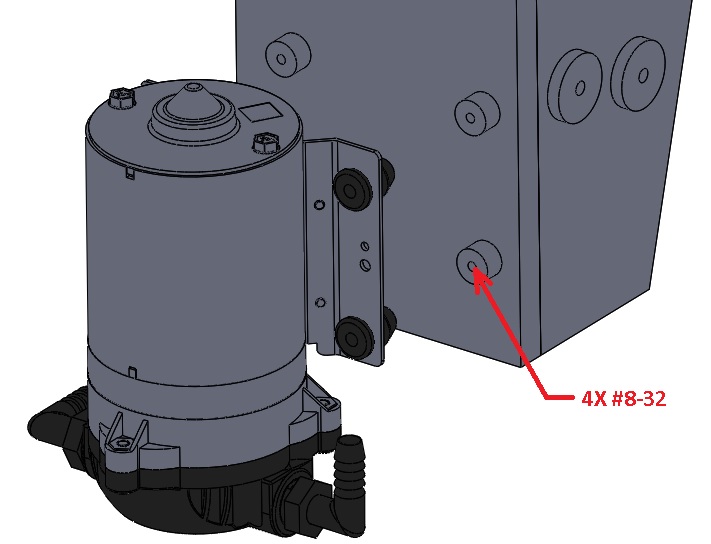

The result is 4 blind threaded holes in solid PVC plastic for the pump.