Here is my....adventure...If you have any questions feel free!

I have a 1985 SE V6 that I have owned since new; Over the years I have done a number of mods- 88 rear subframe and brakes all around, Getrag 5 speed trans, moved the battery up front, 86-88 GT rear bodywork, and 3.4 L F-body long block. The 3.4 breathing thru the original 2.8 induction system doesn't pull beyond 4600 rpm....I found out that the "pinch-point" in the 2.8 manifold is right where the main passage blends into the plenum....A guy actually did some flow bench testing and proved that between modding the manifold and opening up the Throttle-body, it was the manifold that made the big difference. Also, I never did like the 1985-86 "Decal" manifolds- The later ones have the "Fiero" name cast in.

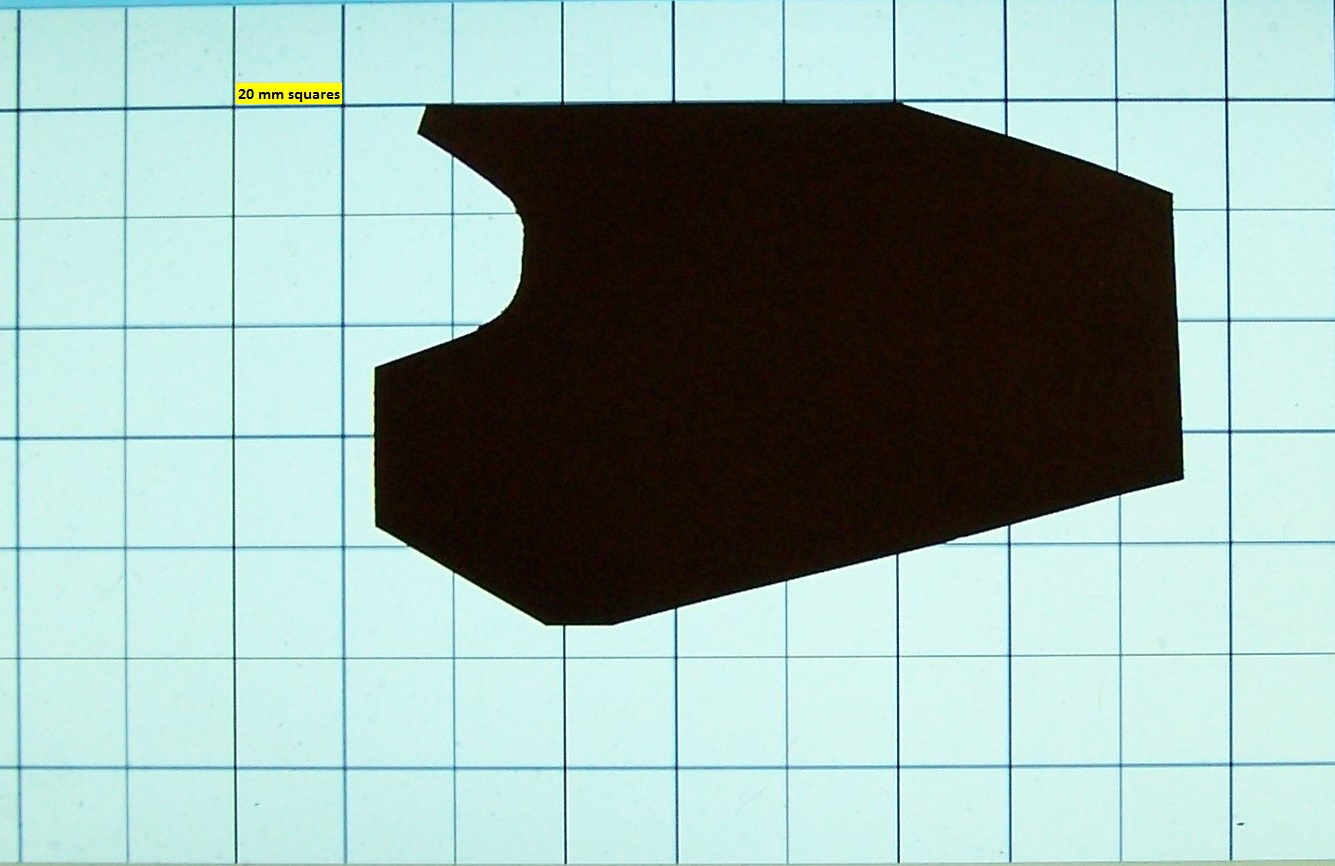

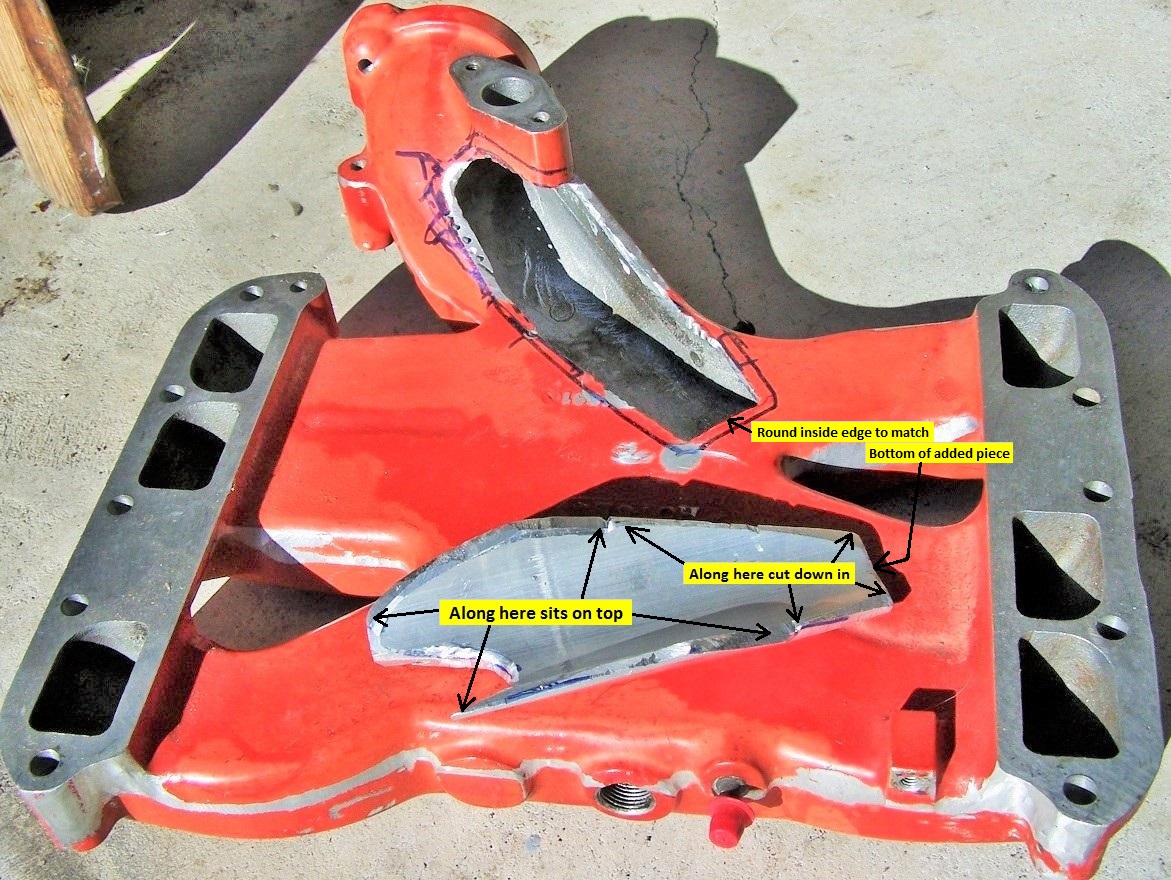

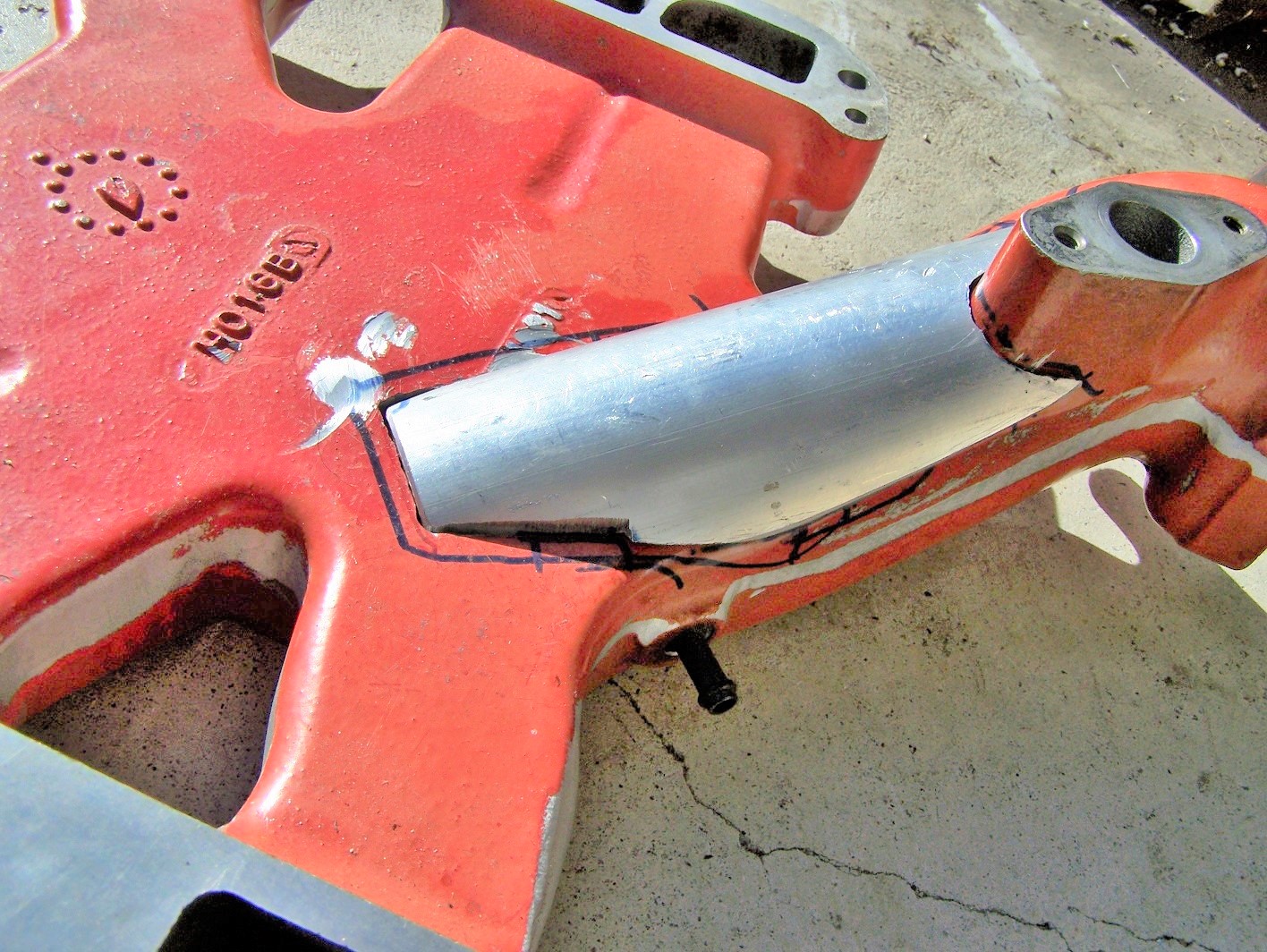

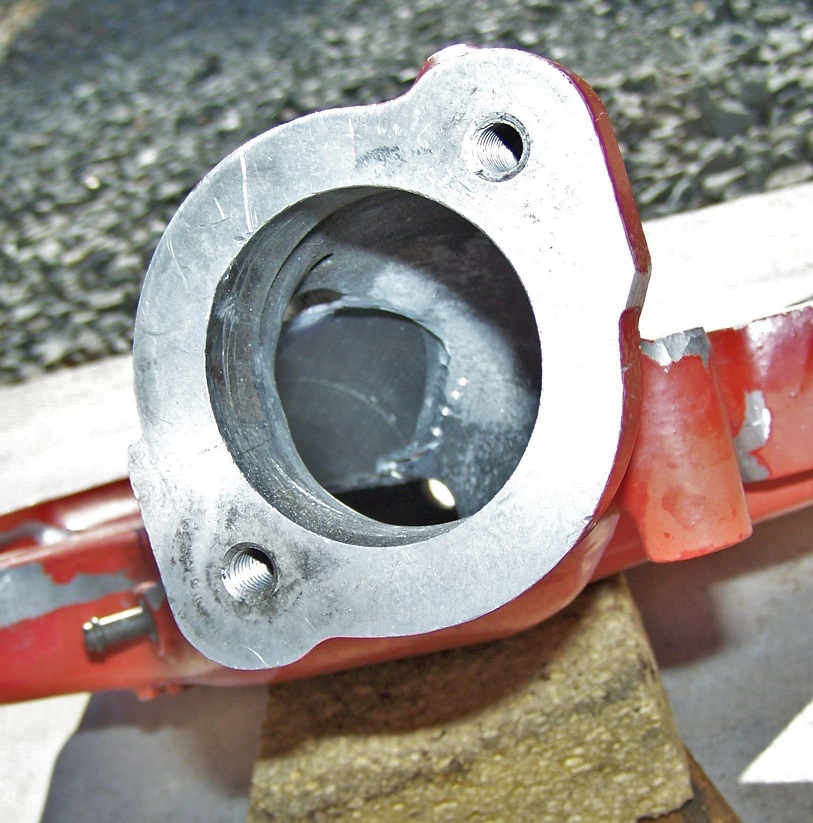

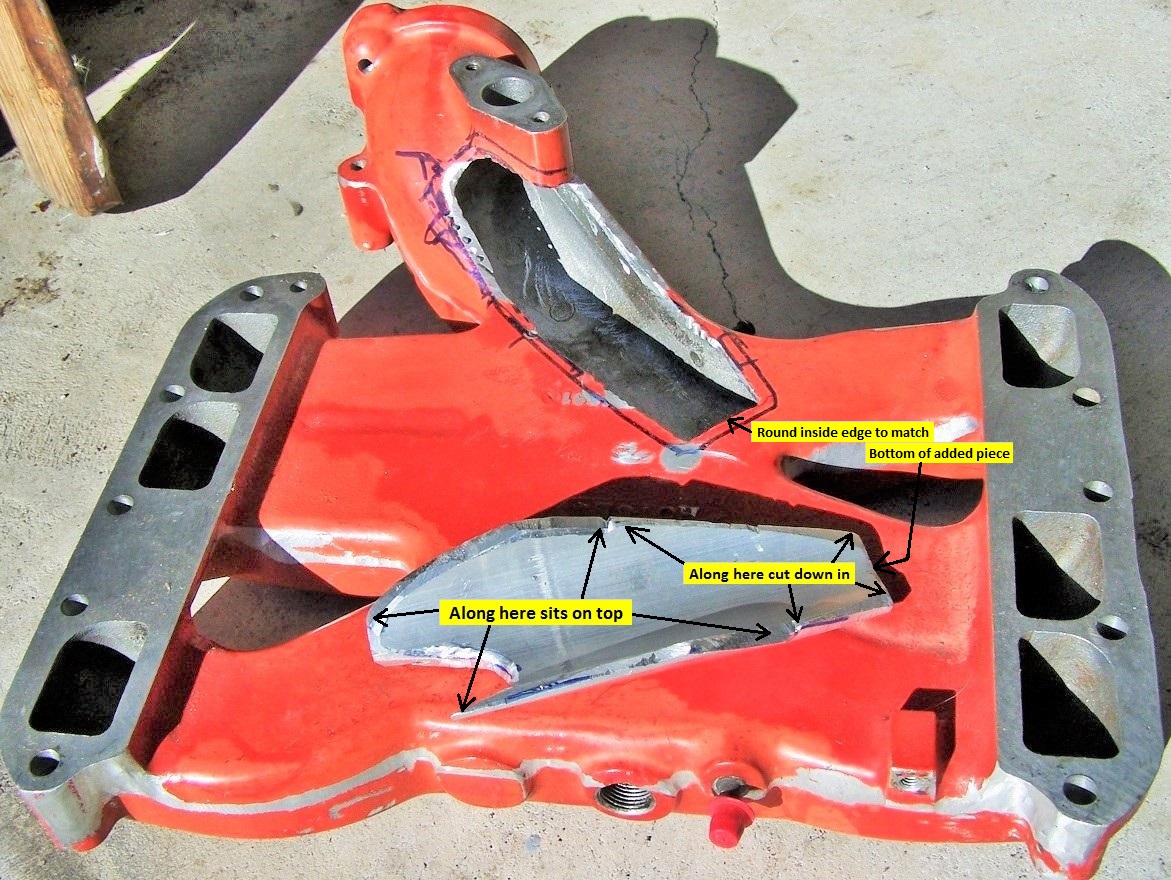

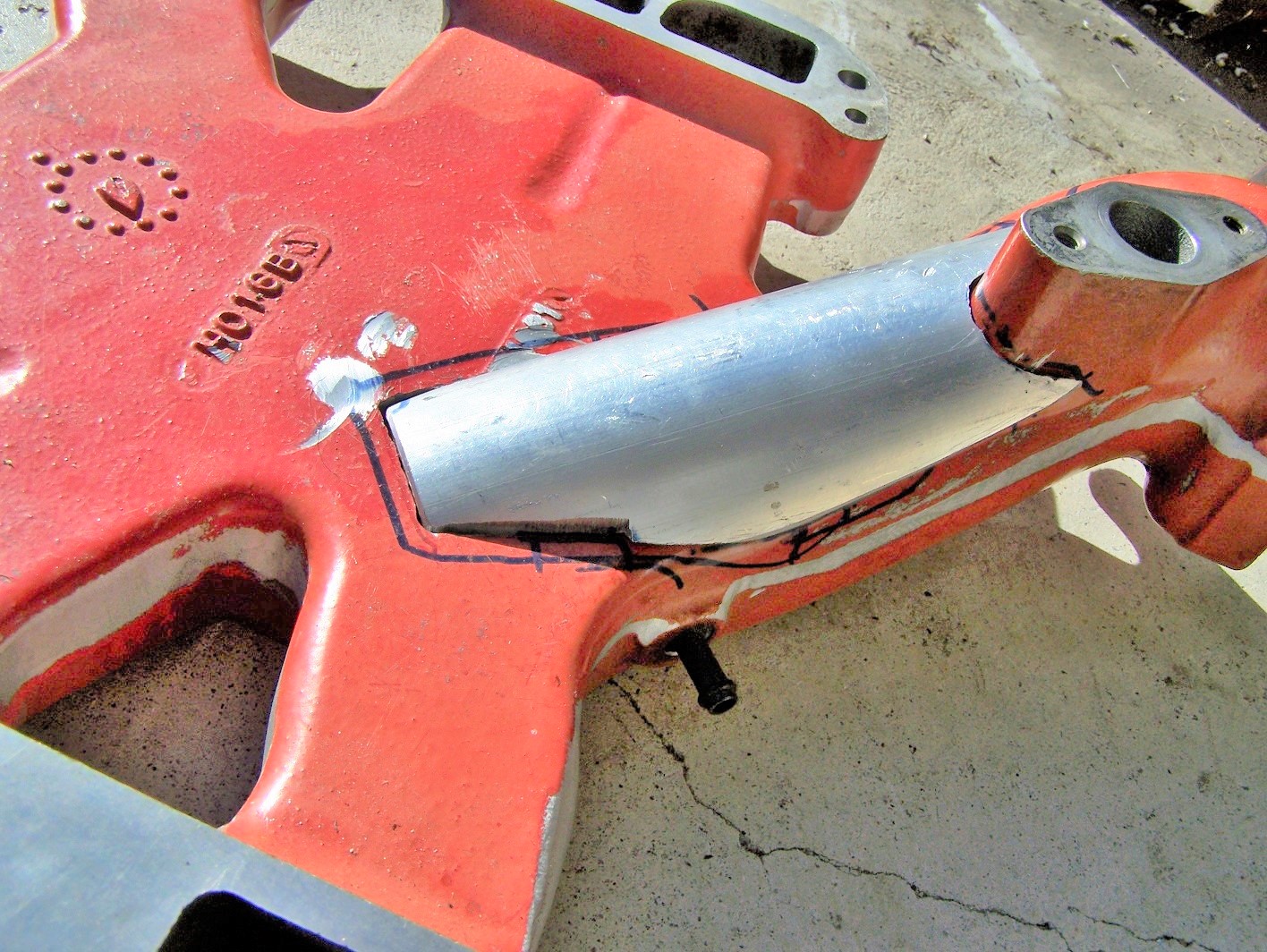

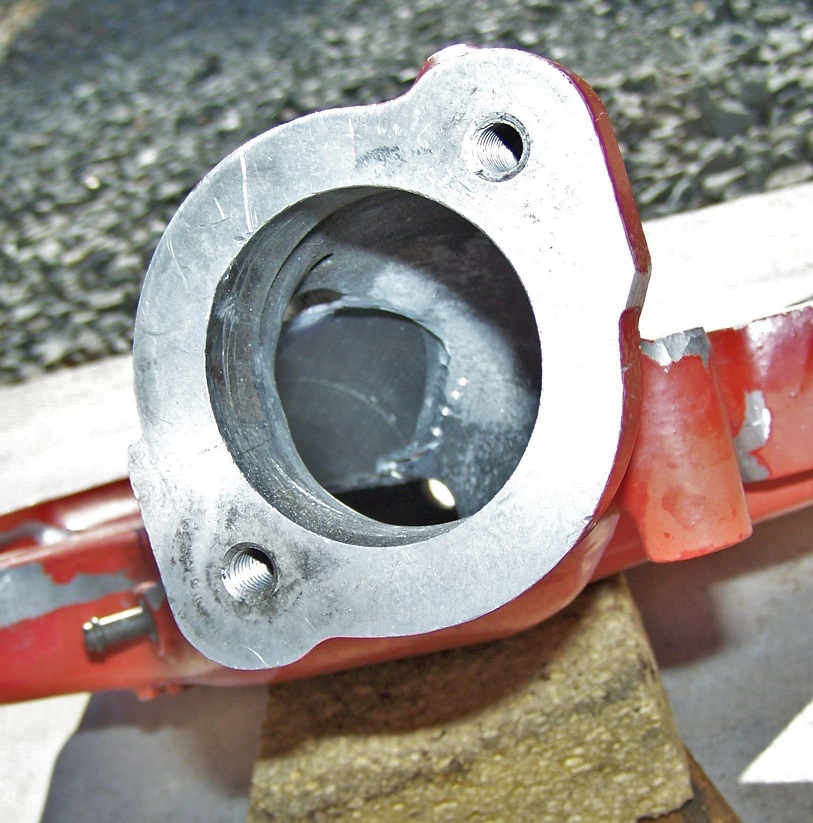

I found a 87-88 upper manifold in the junkyard, and then bought some 1/4" thick aluminum tubing 2" ID and started slowly trimming it and the manifold to blend it in to open that point....It was very time consuming but since I retired I had plenty of time. A friend who is a great welder welded it up for free. I also took some time smoothing the casting lines and removed the cast on mounting for the coolant lines to the TB. I also want to state that you should save the PCV nipple after cutting away the section of manifold where it mounts- any screw-in nipple will stick down farther and interfere with the lower manifold and or fuel rail- In fact, I actually moved the mounting point forward to make it clear the rail. Drilled the hole so a "Tight" fit and hammered it home with some RTV to make positive seal.

Now I needed to paint it- prepping entailed stripping the rest of the paint off the manifold, so I ground and sanded it, then ground and sanded some more- If I was to do it again, I would use some form of chemical stripper (It took me a month of work) I also noticed some pits in the fins and "Fiero" part of the manifold- but figured that once I was done painting I would just sand that area down eliminating the pits.......

I selected Duplicolor engine enamel with ceramic in Chrysler red along with their Primer w/ Ceramic. I didn't want to get any paint on the screw threads for the throttle mounting or the MAP sensor, so I ran some spare screws into them to protect them. The one at the farthest "Left" of the manifold was one with a large washer so I could hang the manifold (Securely) from a hook for painting.

I taped off the openings and wrapped the nipples with tape also- I also taped off the fins and Fiero area so I wouldn't have to sand a bunch to remove paint......Wiped it down with Duplicolor Grease and wax remover, then started painting it. I had read the directions carefully (Yes- I turned in my Man-Card!) and had written a time line for priming and painting; Lite prime, 10 minutes, lite prime, 10 minutes, medium prime, then 45 minutes, lite paint, 10 minutes, lite paint, 10 minutes, medium paint, 10 minutes, medium paint, then 3 hours...at which point I pulled off the tape (Carefully) and then stuck it in my dryer at medium heat for an hour (My dryer came with a "Shoe rack" and I have used it before drying cleaned parts or painted parts)

Two days later I started sanding the fins and "Fiero" area.......Started with 60 grit, then after a few days changed to 180 grit, using a wood sanding block and going slow- so as not to scratch the new paint...and then I realized that those dang pits were deeper than I had originally thought- one was definitely at least 1/16" deep! The sad thing is, if I had been smart (Haha!) I would have had my welder friend just tap those and filled them....now I am afraid it will cook the paint off- Luckily my car is no "Show car" so it's not that important- but a word to the wise- get everything done BEFORE painting!

Testing; Before installing the new ported manifold, I tested the car by going out to the Dublin grade on 580.....In Dublin I headed up hill (Going west) with a 5-8 mph head wind, and also with a 150 lb passenger. In 4th I was able to get the car up to 4500 rpm but then it basically stopped accelerating.

After installing the modified manifold, I took the car out (With that same passenger) to Dublin and headed up the Dublin grade again....It seemed to more rapidly accelerate up to 4500, and then continued up past 4700 and was still pulling. Not a huge change but noticeable.

Some others have shortened the individual runners which has the effect of moving the resonance up in the RPM range (moving the HP and Torque peaks up)...sounds good in theory- But the problem is you are then at a disadvantage because of your gear ratio; You actually want the Power band to be as low as possible in the RPM range. When I swapped in the 3.4, it added (Approx') 20 HP....But my 0-60 dropped from 7.5 to 6.5 seconds- that would require a bigger HP increase- but what made the difference was that the power band was at approx' 1000 rpm lower- which would be like changing the differential gear to a better (Higher numerically) ratio.

I suspect that a minor mod to shorten the runners along with this upper plenum mod would net the best results....

Addendum; I could have done a better job of blending inside after the welding was done, but truthfully, I was tired of messing with it. The area around the EGR mounting is really difficult to blend well.

[This message has been edited by cvxjet (edited 05-27-2020).]

)

)