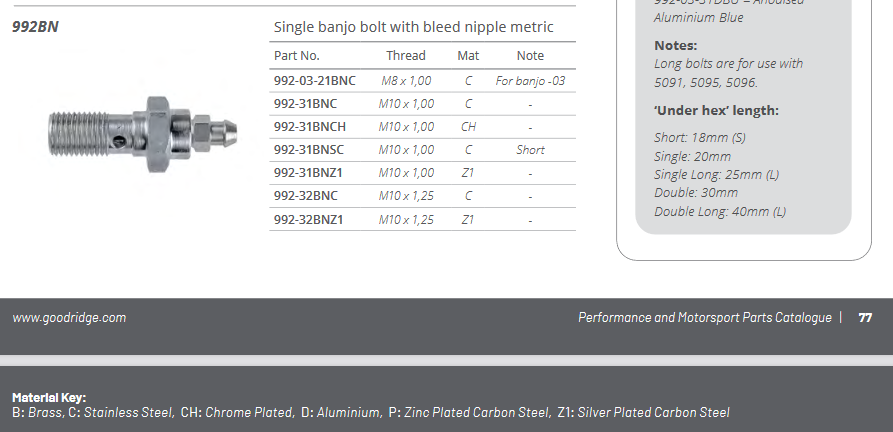

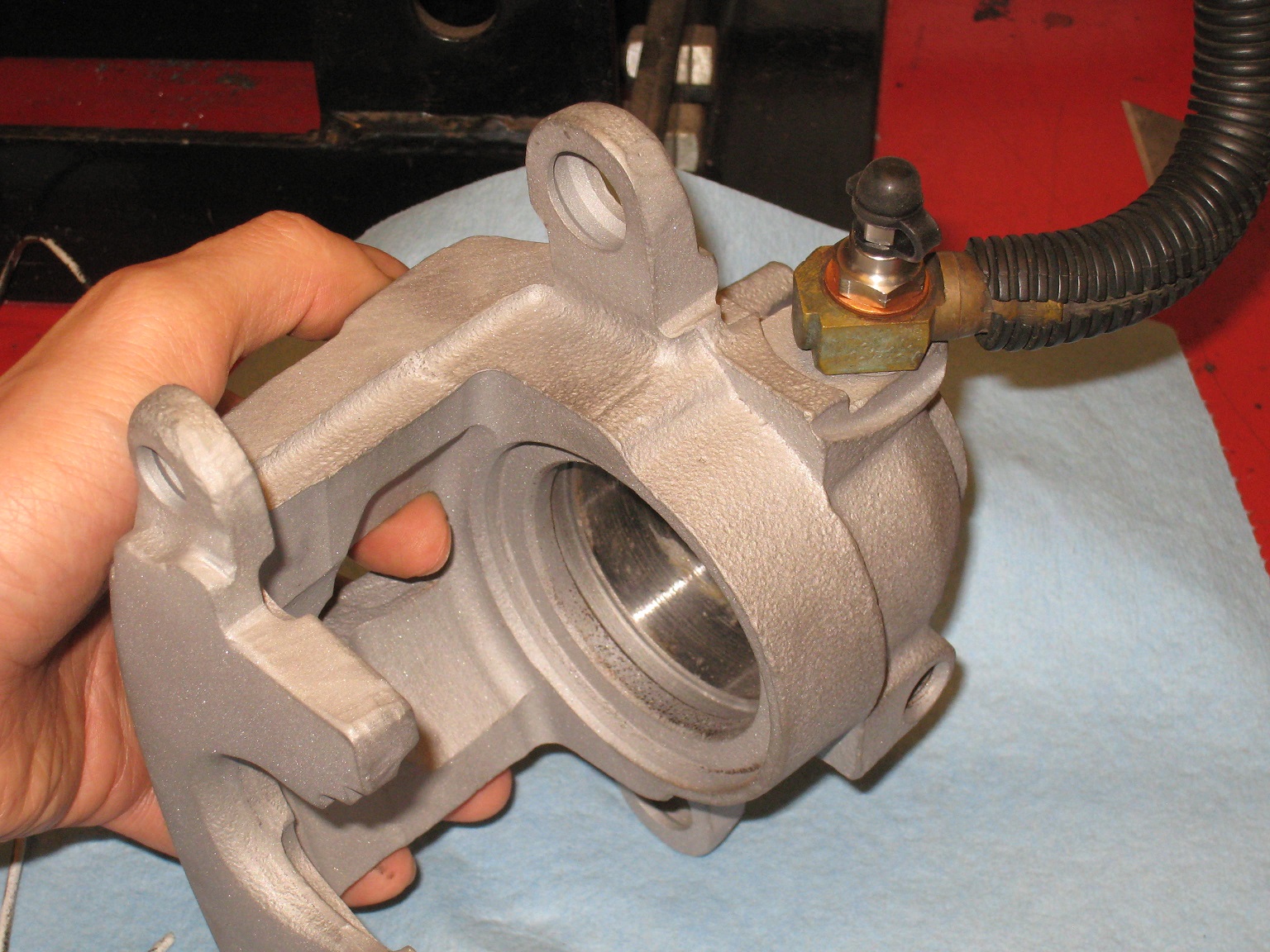

The Seville caliper has an M10x1.5 banjo bolt thread.

The Goodridge banjo bleeder bolt (and others like it) has a thread size of M10x1.0.

Using a Heli-Coil, the original hole can be converted to work with the Goodridge banjo bleeder bolt. Alternatively, one could purchase custom-made banjo bleeder bolts that would be compatible with the Seville M10x1.5 thread.

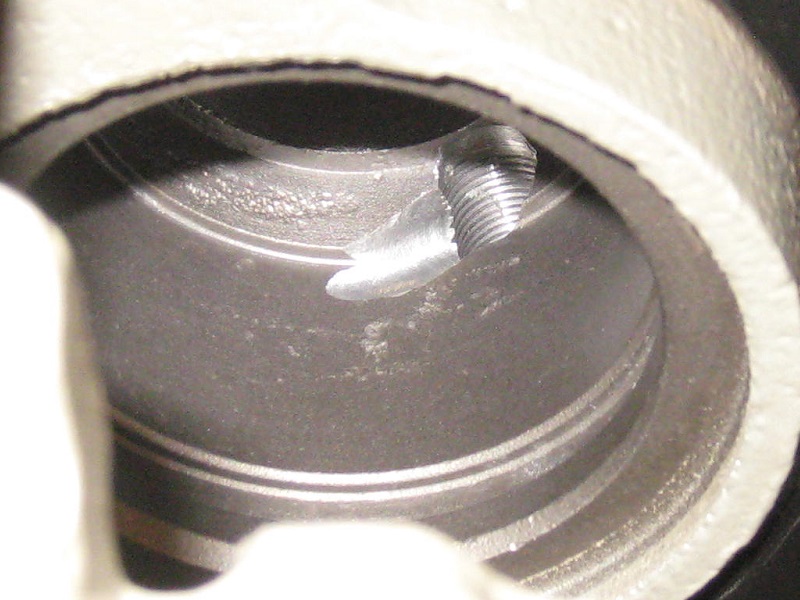

To align the caliper with the drill press, I screwed an M10x1.5 bolt (head cut off) into the fluid port. Then, I tightened the drill chuck onto the bolt shank.

With the caliper hanging in the air, aligned with the drill press spindle, I adjusted the table to fix the caliper in position.

Once the caliper was fixed in place, I could drill and tap for the Heli-Coil.

I like to align the tap with a cone in the chuck. This keeps the tap straight, provided that you apply a slight downwards pressure on the quill.

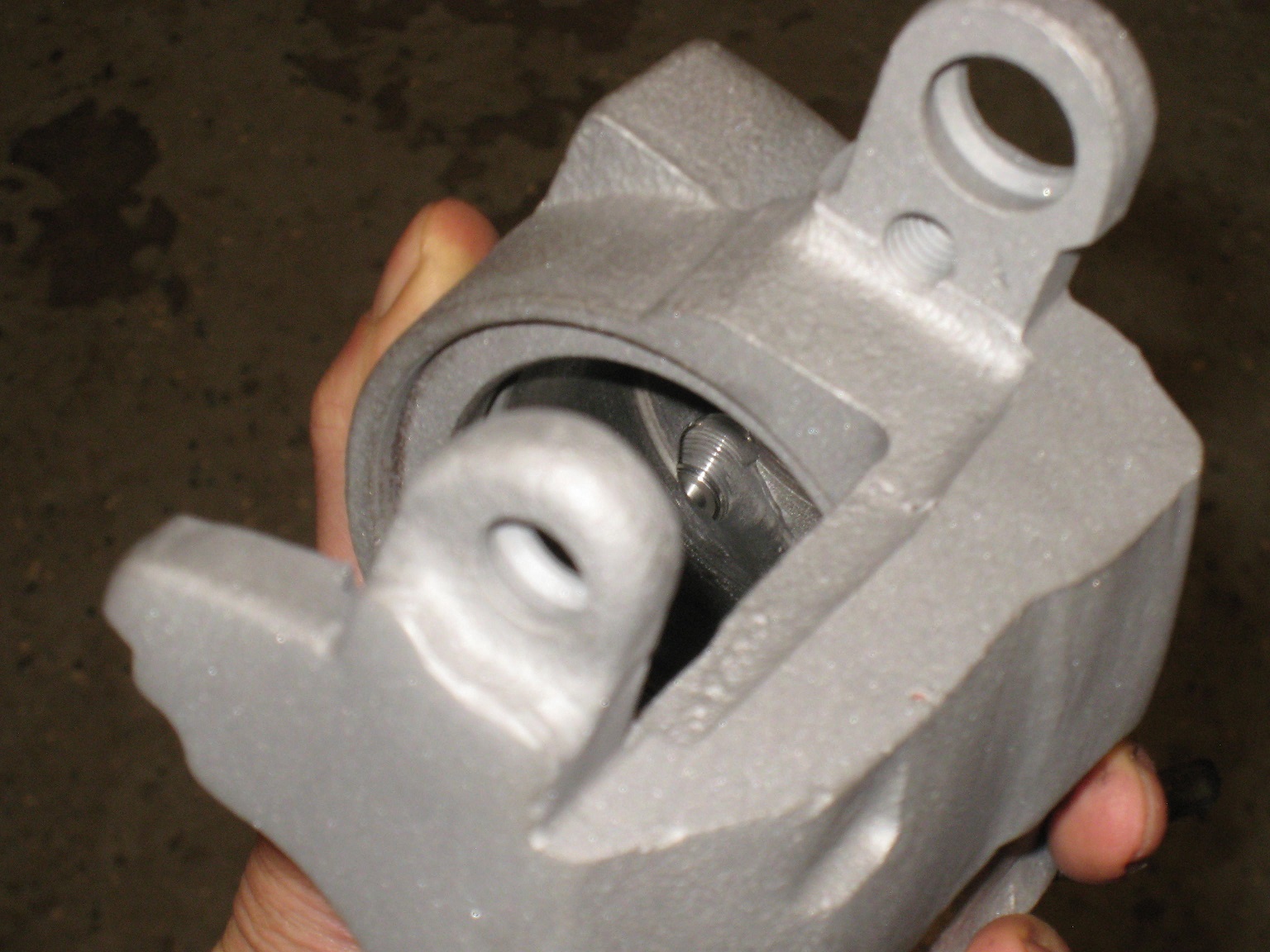

I do not recommend installing the Heli-Coil wire just yet...

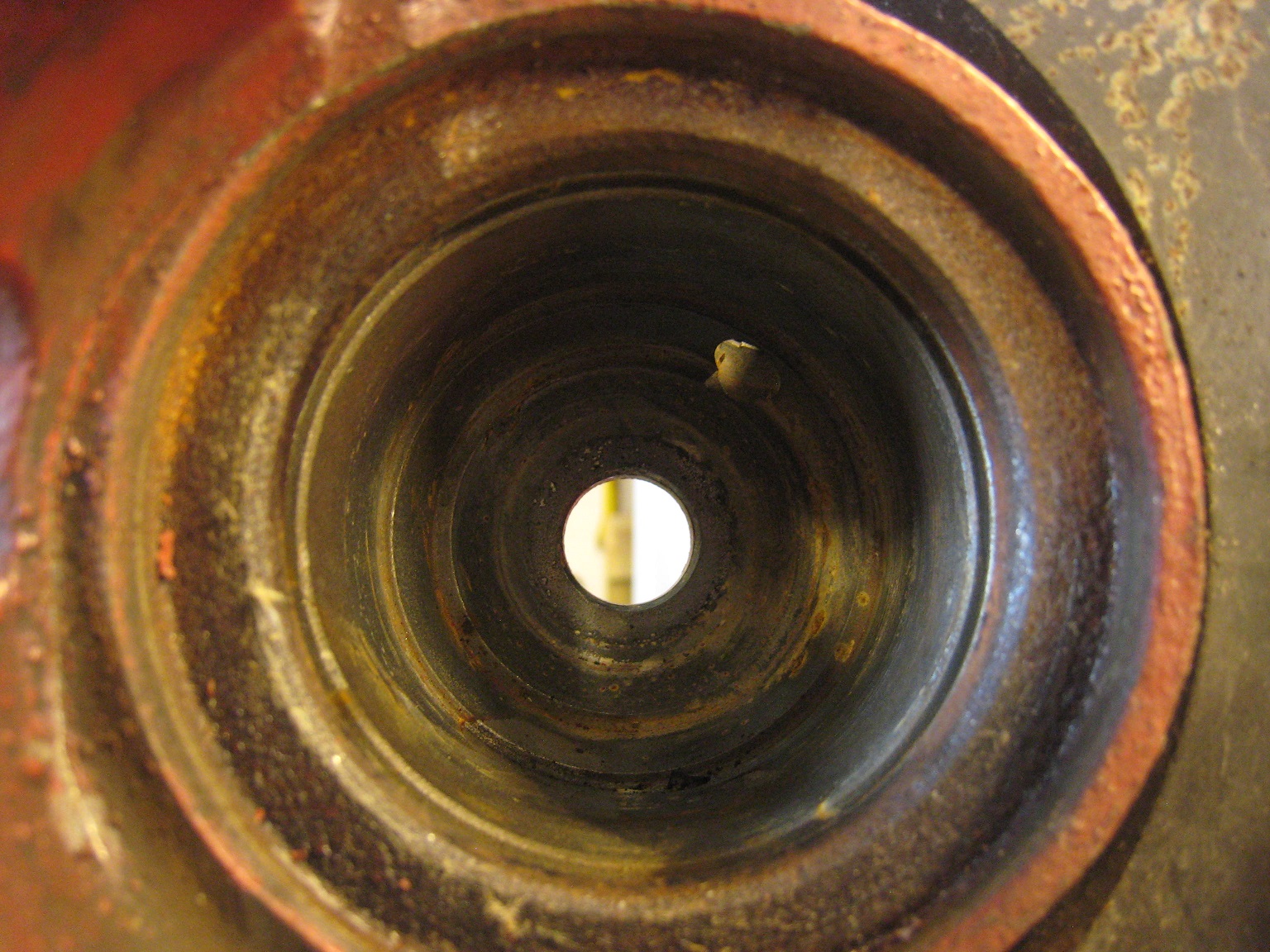

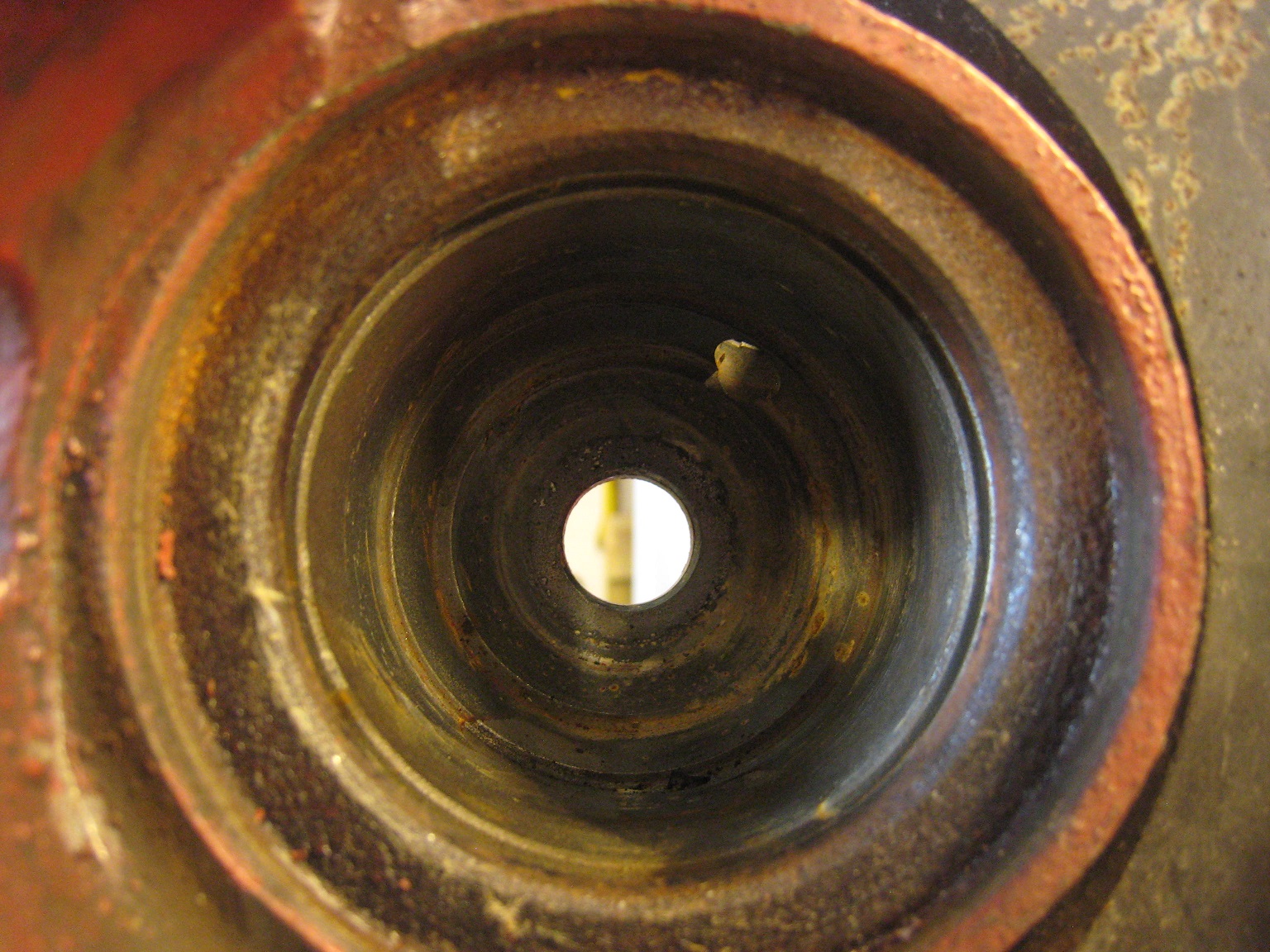

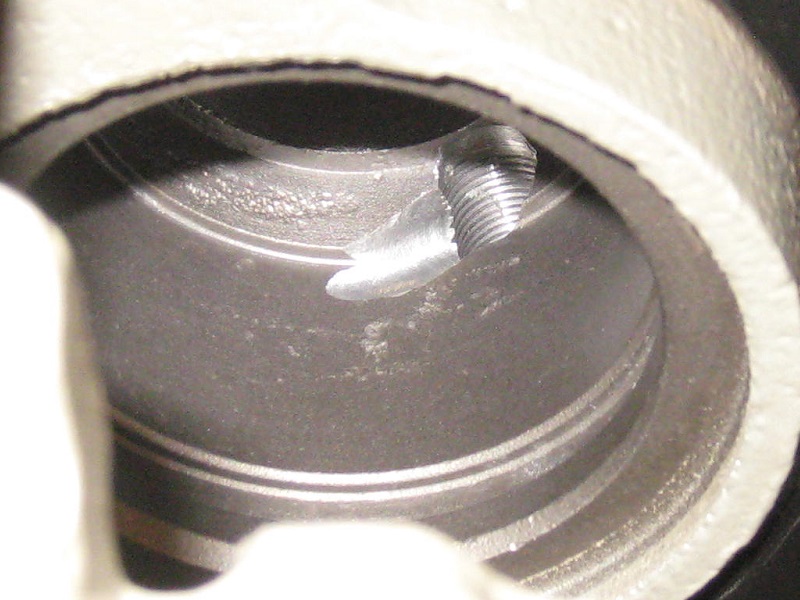

Looking into the caliper, we find that the banjo hole is not quite at the uppermost point of the caliper cavity. This could cause air to be trapped at the top of the bore.

To rectify this issue, a groove should be cut from the uppermost point of the bore, going towards the banjo bolt. There should be a slight constant upwards slope.

To cut this, I used a 1/4" spherical carbide burr on my Dremel. I also needed a 90° gearbox for the Dremel.

I bought this cheap Eyech gearbox from Amazon: