Think the Lifters are "Pumps" to lift oil to the rocker via the push rods.

Lifters need a load from the rods to work. Use web search to see how they work internally.

The P-rods need load just to "seal" the lifter end and drain w/o that rocker loading.

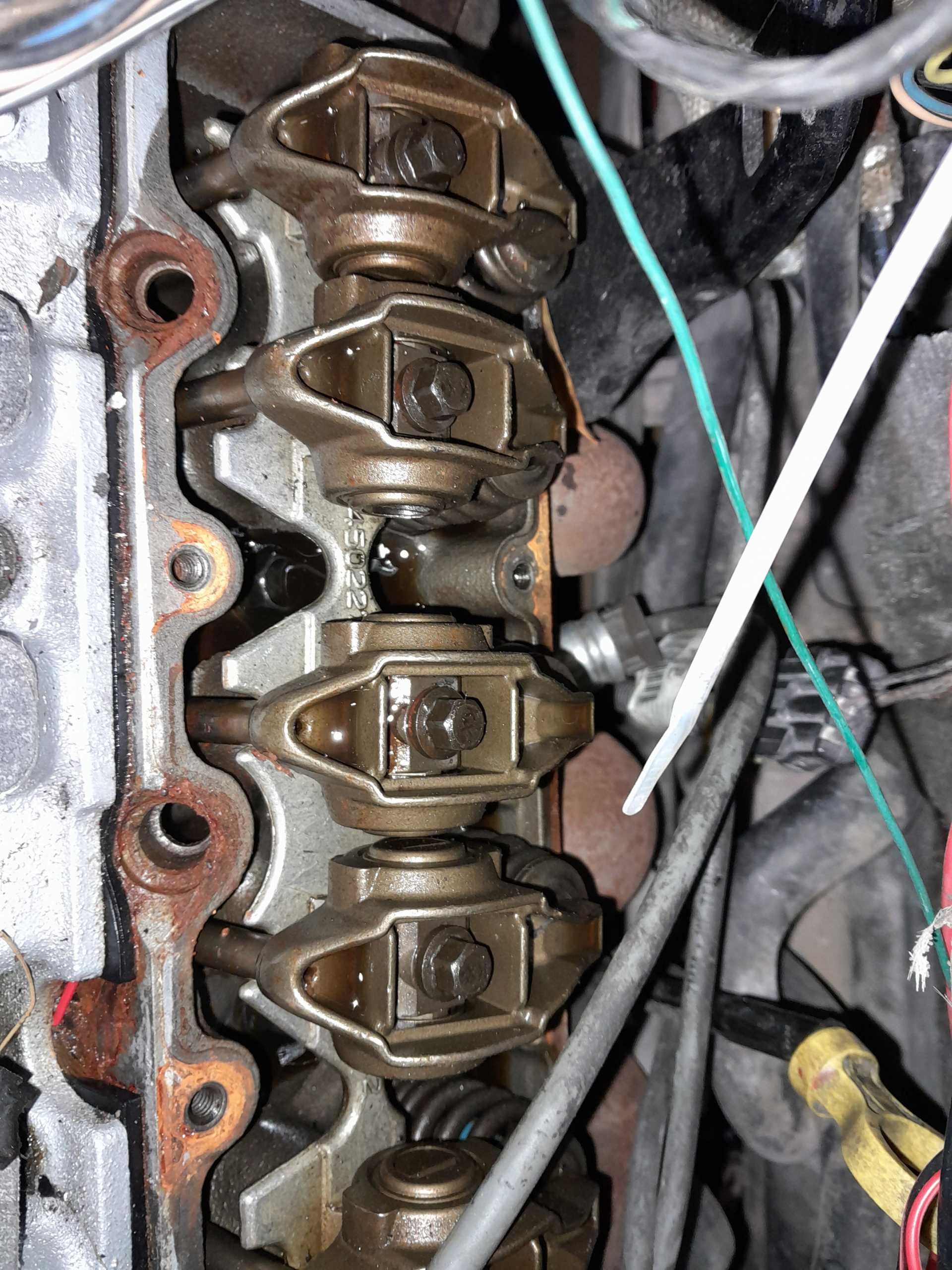

So loosening the rockers often stops oil pumping and takes awhile to start pumping out the top after.

If lifters has oil pressure to start with... Lifters and/or rods can get dirty and stop pumping.

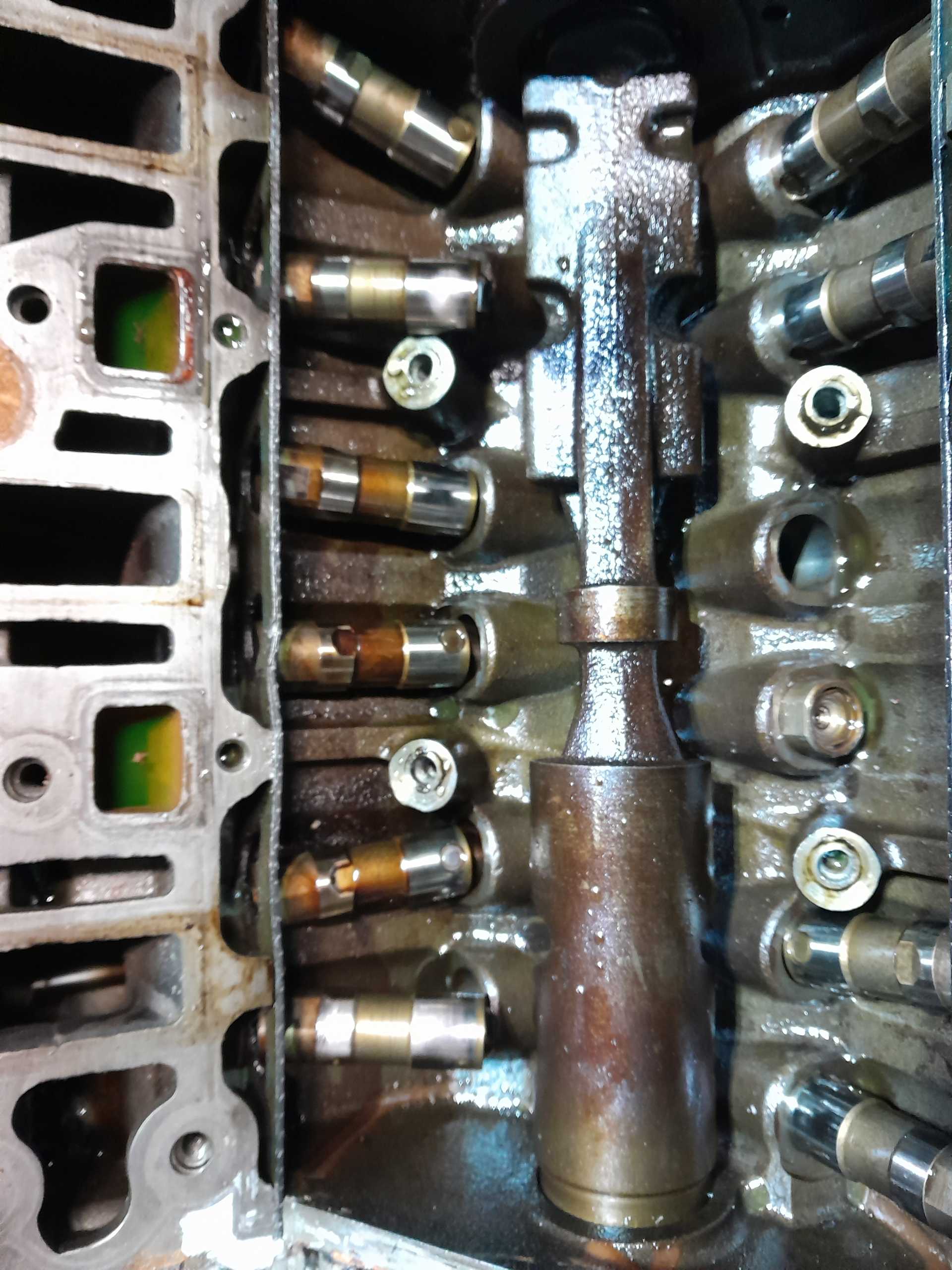

Take out each rod and look inside. Should easy see thru them.

You can clean the lifters but can take time and effort that many can't be bothered.

Example: Inner piston get stuck in crap and hard to remove w/o doing damage to it, outer shell or likely both.

That's after you removed the clip which is harder then many think even when inner parts are new. Worse when have Roller Lifters because rollers make it harder to compress the guts to unload the clip.

I cleaned 2 lifters and said F'ed this and bought roller lifters on RA for my l4 only have 8 of them.

But Note: Putting new Roller lifters on old cams isn't same as Flat lifters. Flat lifters and cam often get dish and egg shape wear that then "eats" the lobes and new lifters.

Ever still you must carefully look at roller tips for odd wear and bearing issues that means trouble. If you can look at the cam lobes too. I used a cheap USB bore scope to inspect the lobes on l4 in the car before installing new roller lifters.

If you can... "Flush" the lifter holes 1 at a time to make sure lifters have flow and engine isn't you problem. Do this before just removing all lifters. 1 at a time so only 1 hole gets a lot of flow to push out whatever crap maybe blocking oil to the lifter(s). If can find the oil flow map and find where lifters get oil start at the lifter(s) near/at first started.

Use a drill to run the oil pump. Using the starter can fry it and pump doesn't make much pressure anyway.

[This message has been edited by theogre (edited 12-05-2022).]

I jacked up the opposite side of the oil pump, added a few extra quarts and I got 60lbs pressure. I cant find an oil map of the motor either. Ill do smore diggin now and try to find which way the oil comes into the lifter galley so I can do the flush u mentioned. Gonna drain some oil n check for glitter, cue the jaws music........

I jacked up the opposite side of the oil pump, added a few extra quarts and I got 60lbs pressure. I cant find an oil map of the motor either. Ill do smore diggin now and try to find which way the oil comes into the lifter galley so I can do the flush u mentioned. Gonna drain some oil n check for glitter, cue the jaws music........