The Iron EGR head is with it's new owner, and the 2 Barrel Intake is lost in UPS hell.

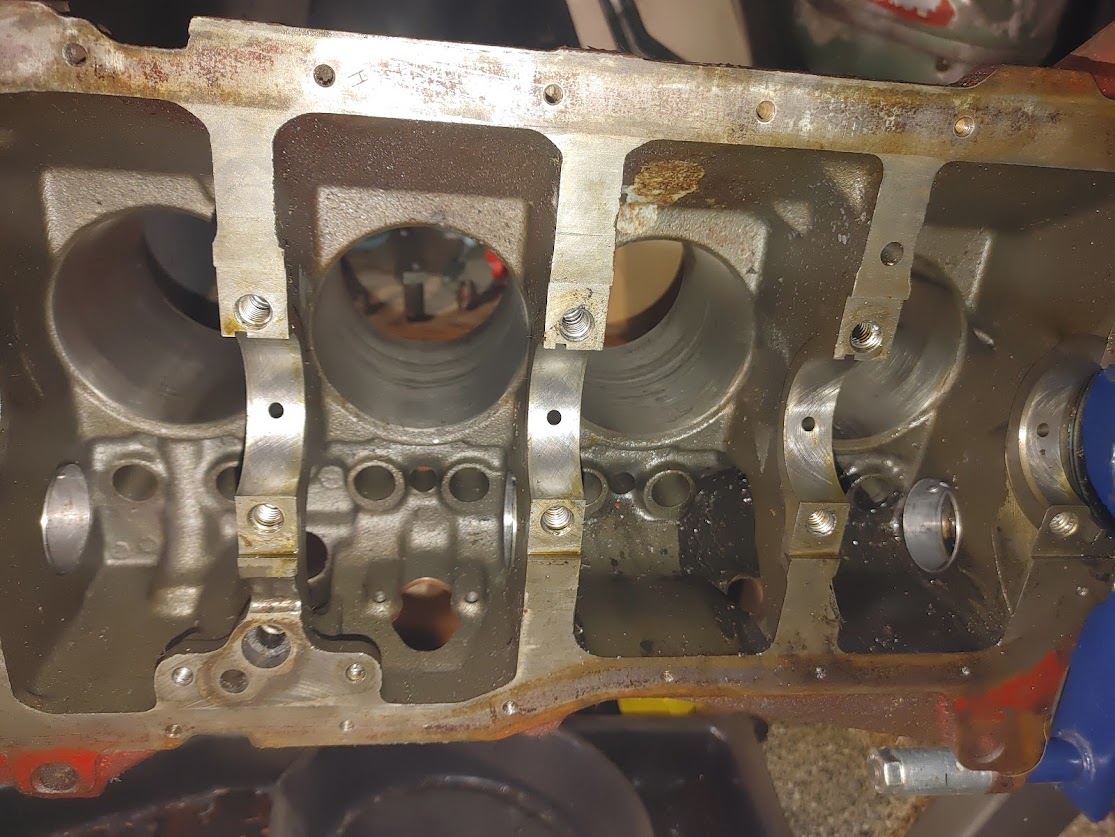

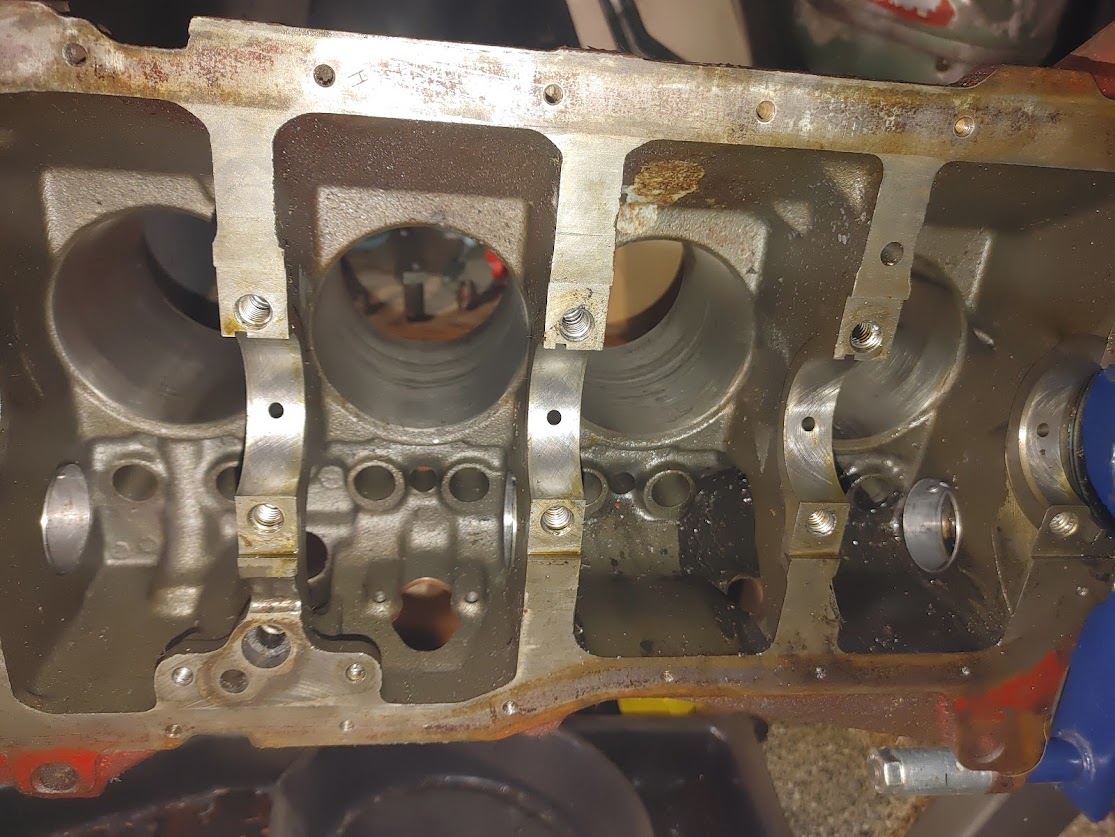

I did work on tearing the block down further.

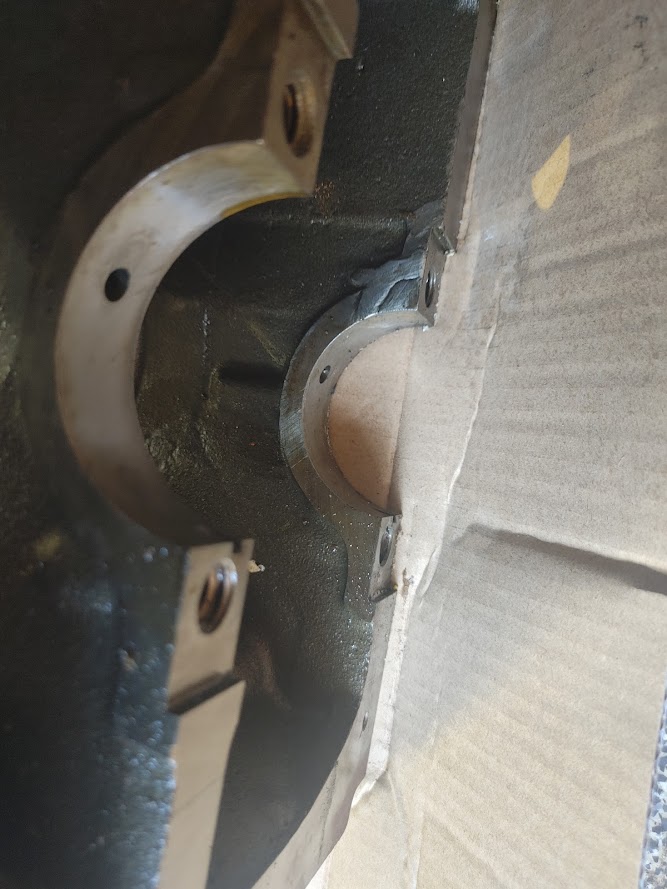

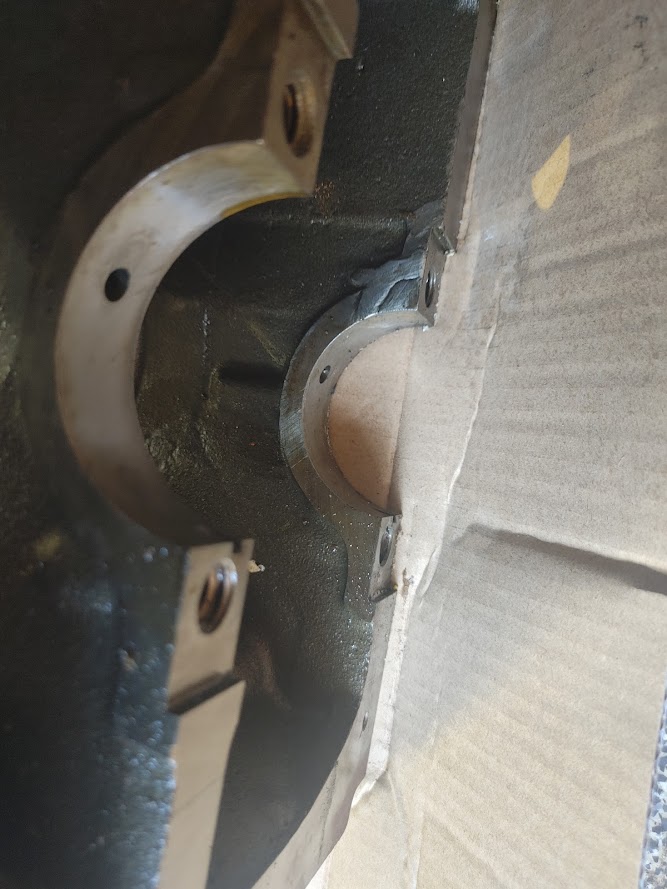

I found a dirty little trick I am not too happy with:

A welding Main saddle, but it appears to be an adequate repair.

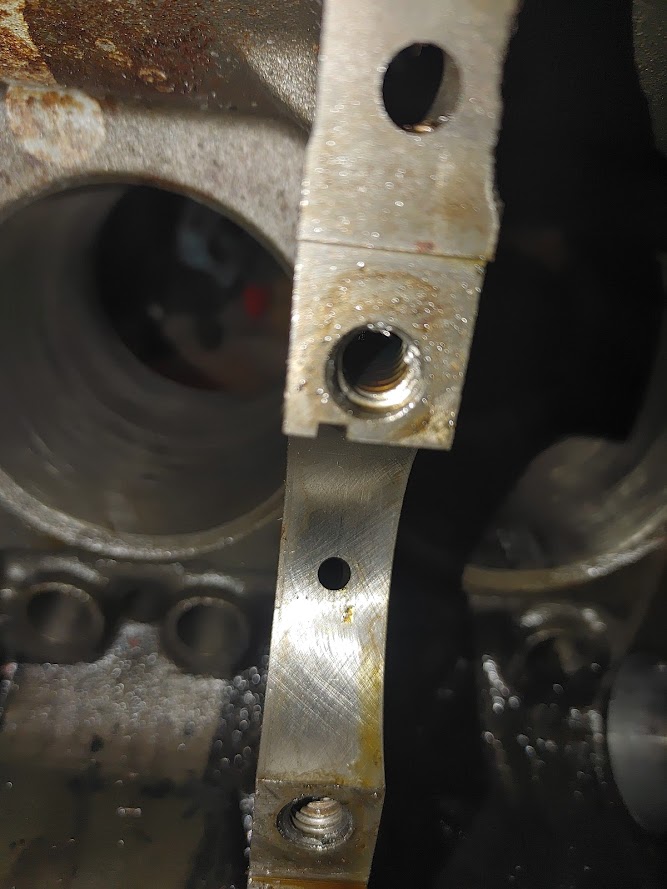

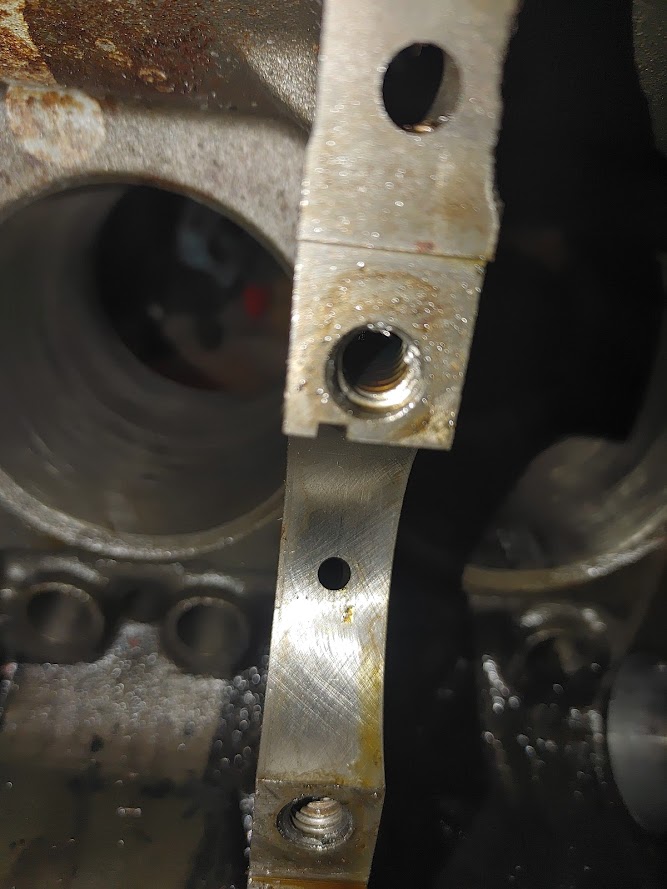

Unfortunately the builder of the engine decided to forgo the prescribed 1/2" main studs and Heli-coiled the block for 7/16 studs in all the holes to replace the 11mm threads the SD4 came machined with.

The OD of a 7/16-14 Helicoil should be 17/32, which is the drill size for a 1/2-13" Helicoil.

The problem is, I have to Helicoil if I want the use the "proper" 1/2in stud since the 7/16-14 Helicoil is larger than a 1/2-13" thread. I don't see there being enough meat in the block at the main bearing split for the 1/2"-13 Helicoil, which has an OD of 39/64".

I don't want a crack to develop if the hole intersects the notch for the bearing tangs.

I most likely need to keep the smaller main studs.