⚠️ Warning: 1. You need much "hotter" iron/gun to solder heavy wire then most have.

50-100 watts minimum to make a good joint w/o big problems that can, often will, fail later.

Like "Weller type" guns have 90 to 140 watts that puts a lot of heat on/in a joint before the copper can heat sink the spot.

Also: Do Not use Lead Free Solder. Most require

More Heat to melt that makes this job harder. Some areas or countries now block lead solders to sell to most to all users but can find it in flea markets etc.

2. Mashing the ends then "tying" wires like above is not correct & can Fail. More so on "cold" joints that results using under power irons/guns etc.

Can twist ends to get

mechanical connection then solder. Example: a Short version of this type twisting... "

Western Union splice"

Or Use non insulated crimps then solder.

3. Flux Core Solder often doesn't get to inner wires for big joints to work. Again more so w/ under power irons/guns.

Flux core often doesn't have enough flux so needs standalone Rosin or other non-acid flux

or have heat problems... flux etc too cold doesn't work, too hots & flux burns before solder works. Second issue common to torches heating whatever to solder.

You can use "tinning" flux that mixes low temp solder in a flux. This will tin fast to see when flux is working. Again, Make sure any flux isn't acid flux.

4. You need "weather/water proof" shrink tube that has "glue" inside.

Doors are very wet areas & joints unprotected will corrode not only attack @ the joint but "water" will wick under the rest of insulation & rot more wire.

5. That's assuming OE & other wires can be cleaned to solder. Many OE stranded wires already have some crap/corrosion/oxides that is near impossible to remove then fluxes fail, more so flux core solder, to clean & solder doesn't work even if "Passes" a pull test right now.

Or...

● Use "water proof" crimps but need right crimper + adjusted right too so won't cut the sleeve but crimp tight to work then heat the tube to shrink & seal.

Use 3M crimps or other real brands. Most don't crimp enough joints to "save money" on no-name crimps but often they are cheap for many reasons & Fail now or later because weak metal used to make them.

● Use

Posi-Tite for 20-18 or 14-16 awg wires. Maybe can use Posi-Lock w/ some silicone or permatex green brake grease to keep out water since is not directly flooded.

But these 2 often hate old wires too for same reason you can't clean to solder. Posi-Lock/Posi-Tite might help because how they work & like many other connections forces the metal to metal contact to "wipe" the crap off if not badly dirty/rotten.

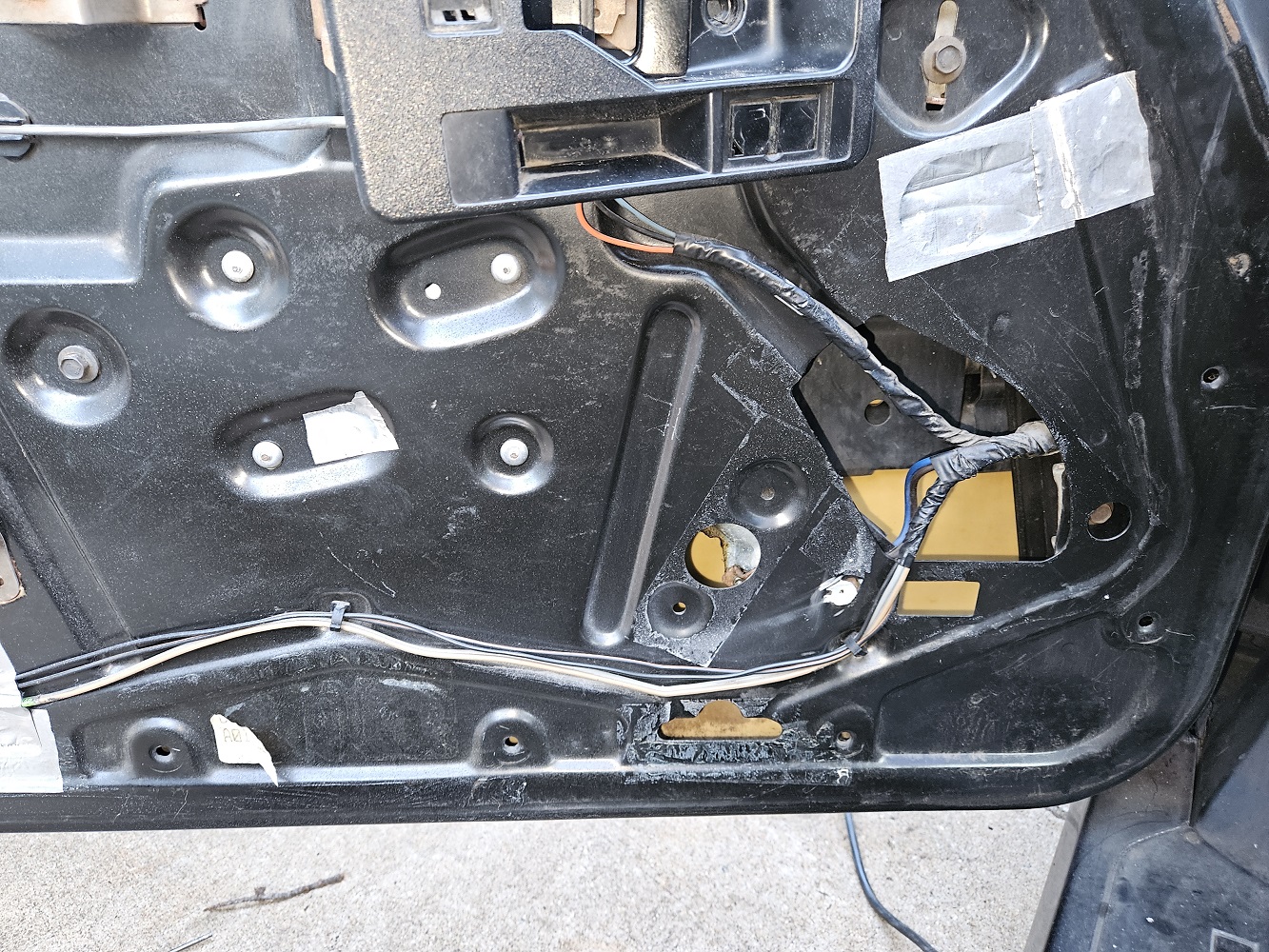

"Doors are Wet zones?" Yes. Even w/ brand new "dew wipes" allows the water & worse will get on most of the door parts when it rains etc. because dew wipes & other external parts don't seal very well or not @ all. Is why most doors have "water proof paper" or plastic on inner door to protect the inner trim etc.

If other plugs in a door are not "water proof" like Metripack or weather pack then use silicone, brake grease or bulb grease on them.

------------------

Dr. Ian Malcolm: Yeah, but your scientists were so preoccupied with whether or not they could, they didn't stop to think if they should.

(Jurassic Park)The Ogre's Fiero Cave[This message has been edited by theogre (edited 07-28-2024).]