What up.

Im starting a new thread to show off my new project!

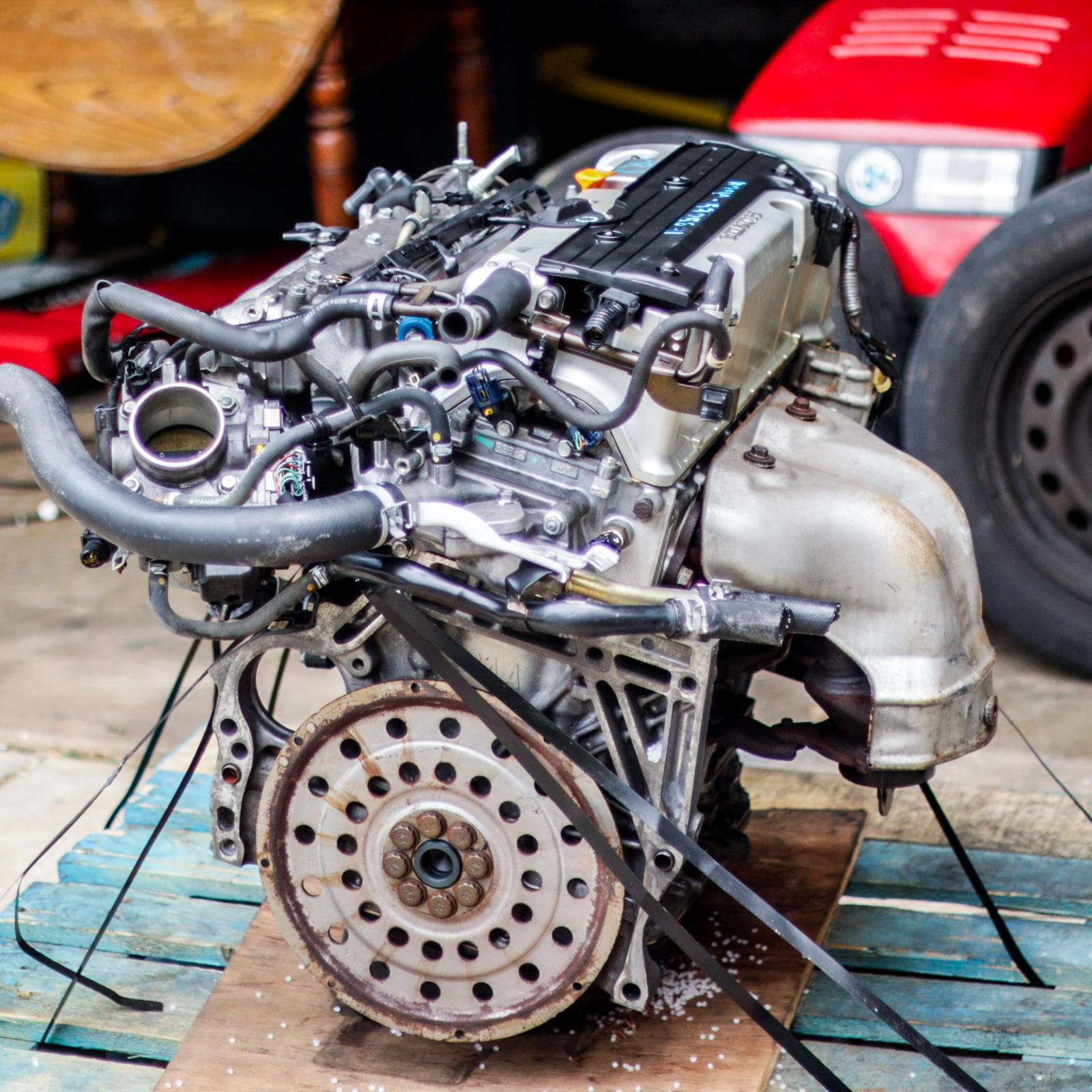

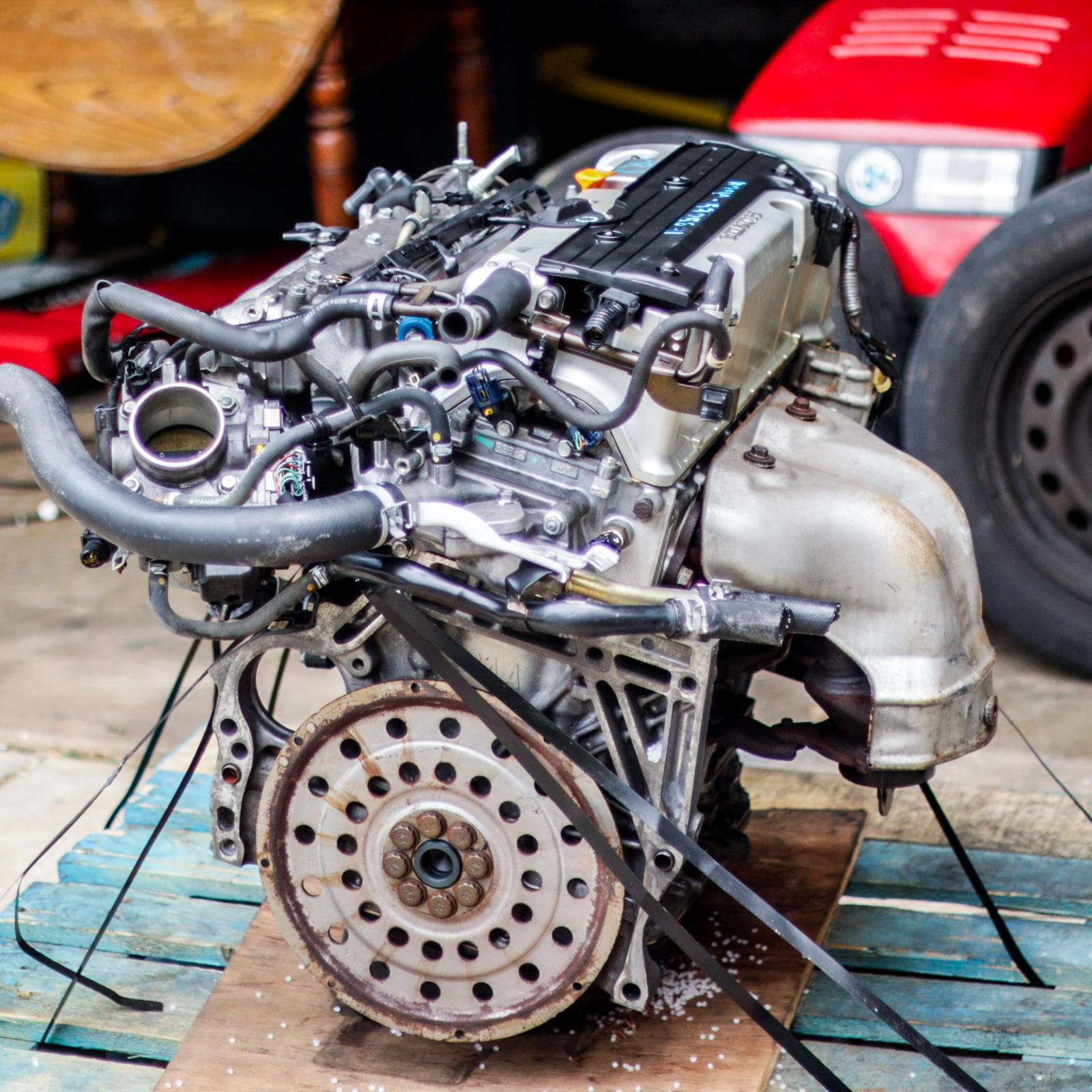

im starting a k24a2 engine swap on my 1984 2m4 (tired of dealing with a 40 yo engine)

I only know of maybe 2 or 3 other people whio have done this swap so i wont have much documentation to help me out on this one, so im going to document it to my best ability on this thread.

I have a low budget and not a whole lot of time so i wont be updating this thread super often but I will as much as I can.

engine shipped today so im excited to actually start working on this thing.

currently in the process of removing the old duke out of the car.

UPDATE 1 (9/28/24):TRANSMISSION

I managed to get my hands on a pretty decent transmission for the K series.

I ended up going with a 5 speed manual out of an 04' Honda RSX. I thought 6 speeds would be too much lmao. I'm hoping to get a stage 3 clutch and lightened flywheel for a snappier drive and I have my eyes on a few different kits.

My back seat is all stained now lol.

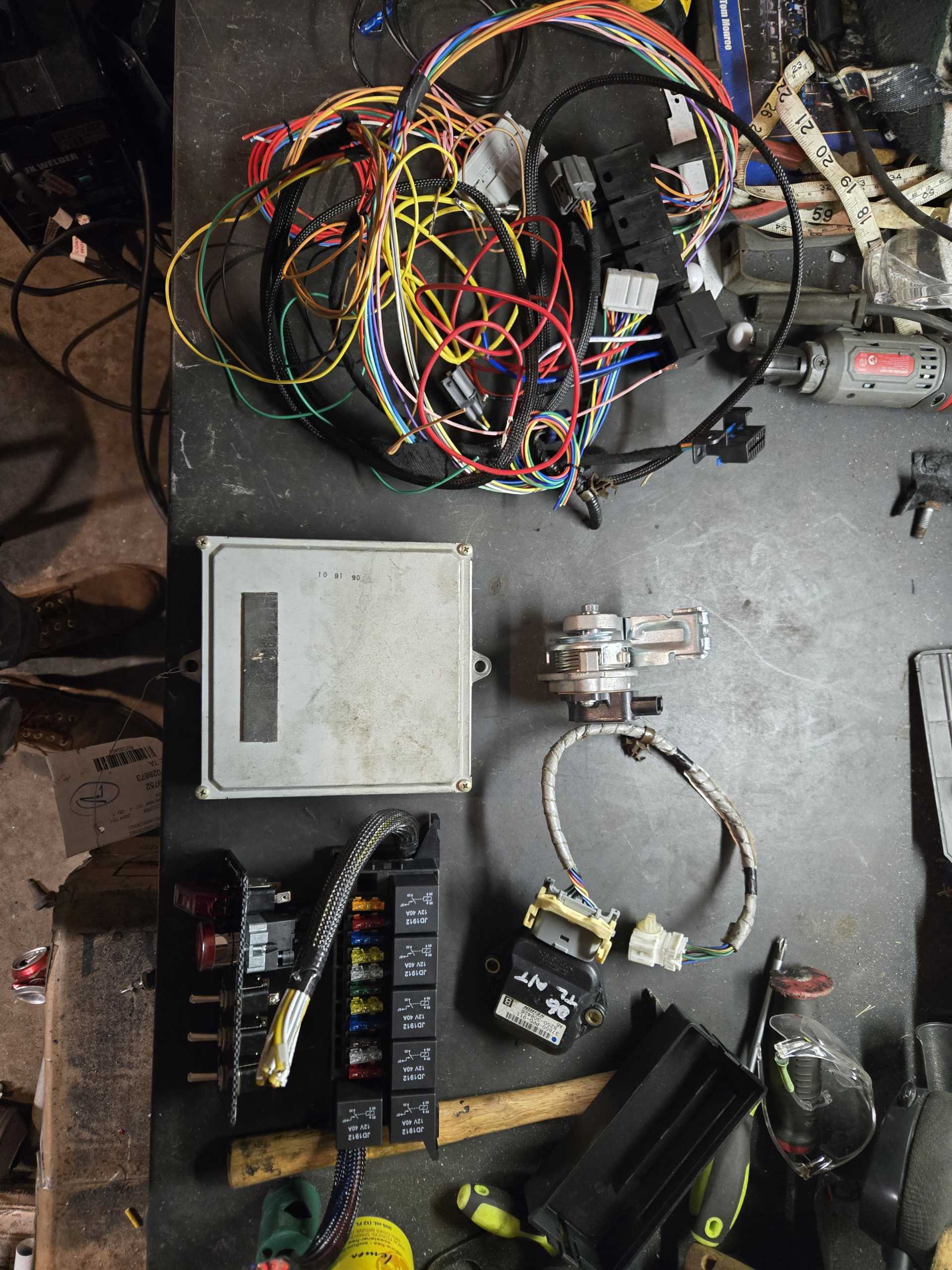

Currently I am working on getting the ECU and stuff wired up and hoping to get the engine running on a stand. I haven't actually worked on much, mostly just collecting parts for the build, I haven't done much assembly. Ill go more in-depth with pictures of parts and the set up I'm going with within the next week most likely.

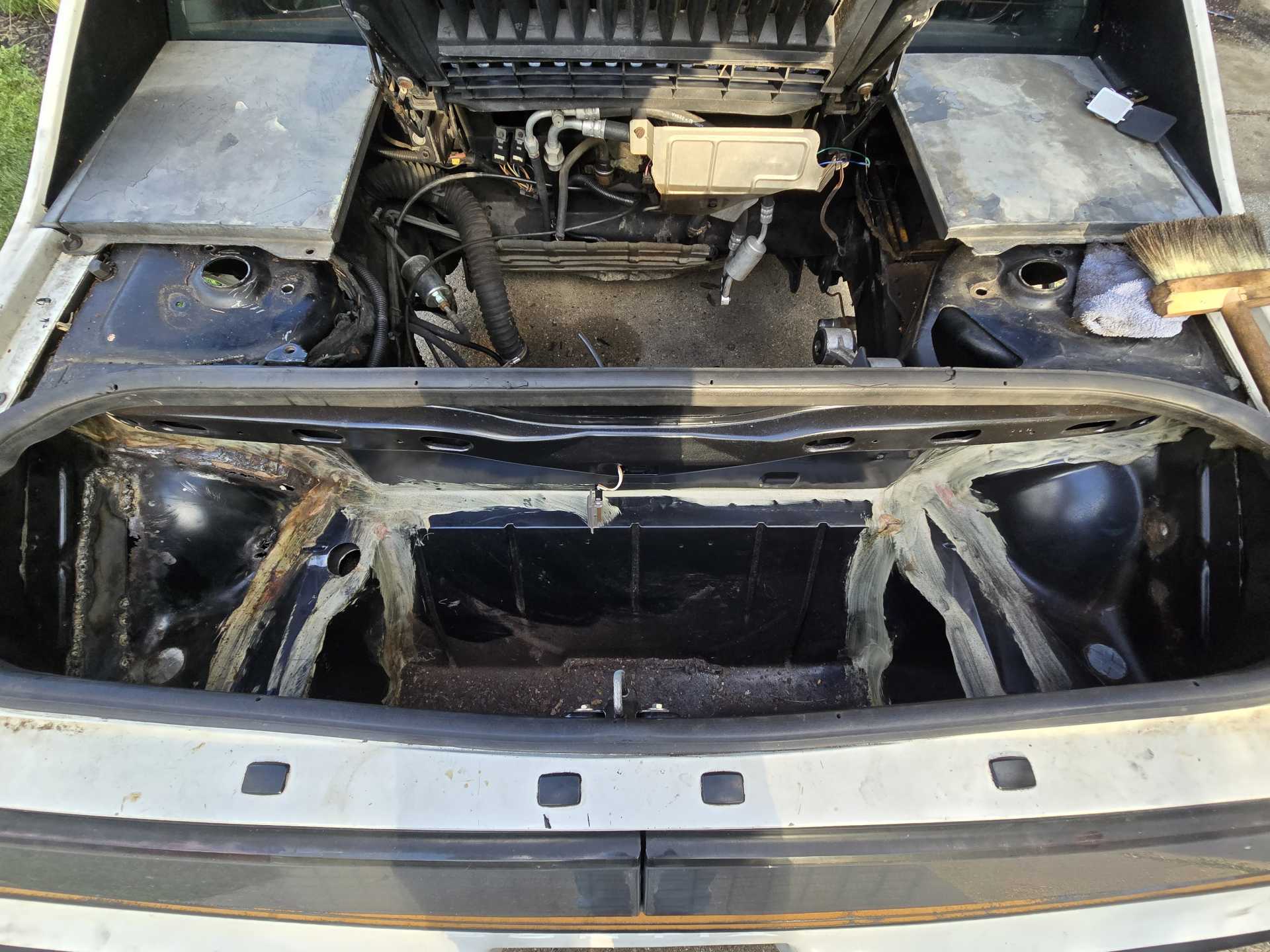

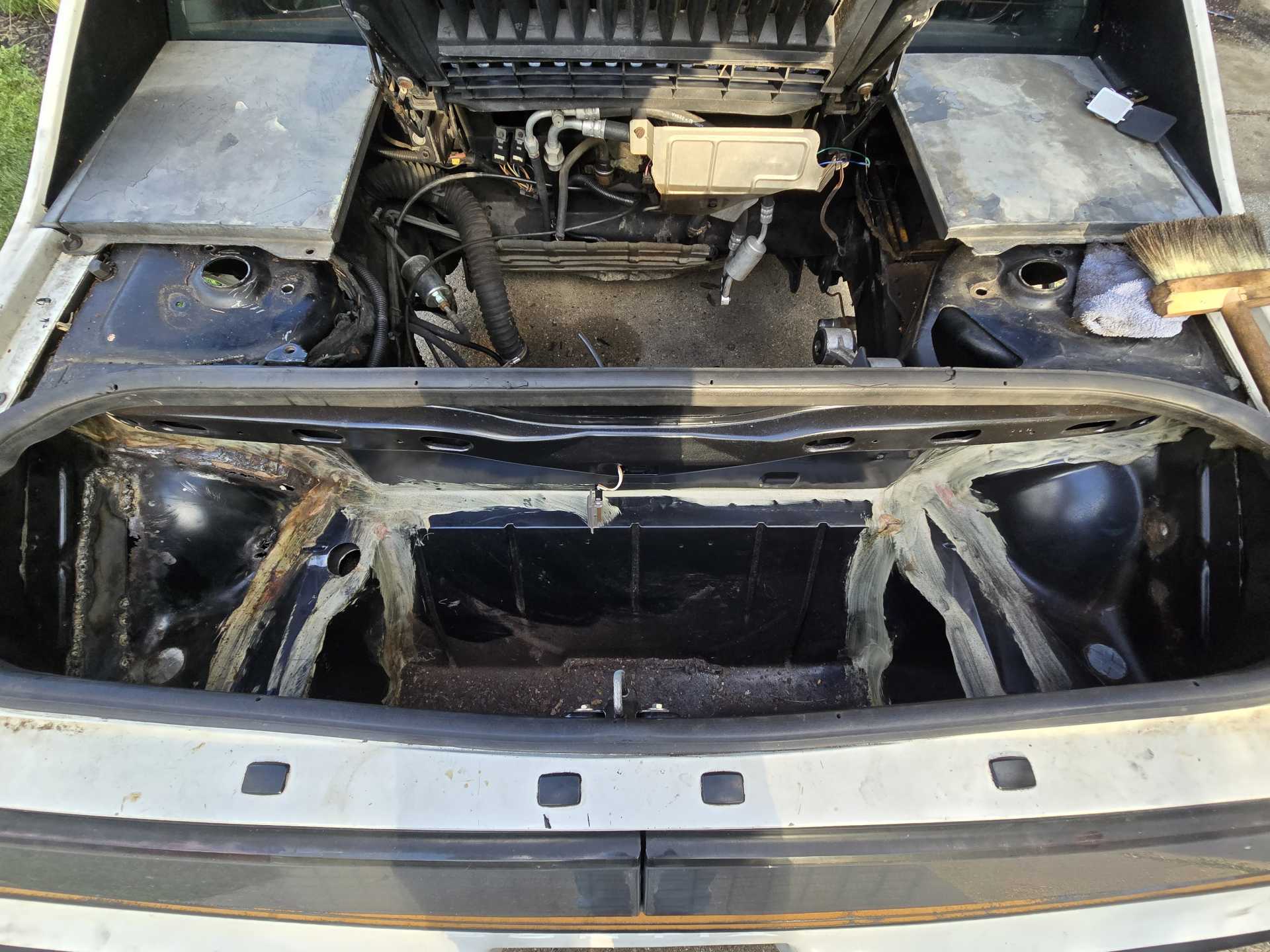

One minor thing I have done was I did a little rust repair and repainted the engine bay. I was super lucky since most if not all of the rust was surface and I didint have to do much actual rust repair.

Before

After

If you have any questions let me know.

this is my first time legitimately attempting to document things so if you have any advice/criticism on my work, let me know please it would be greatly appreciated.

UPDATE: 11/4/24

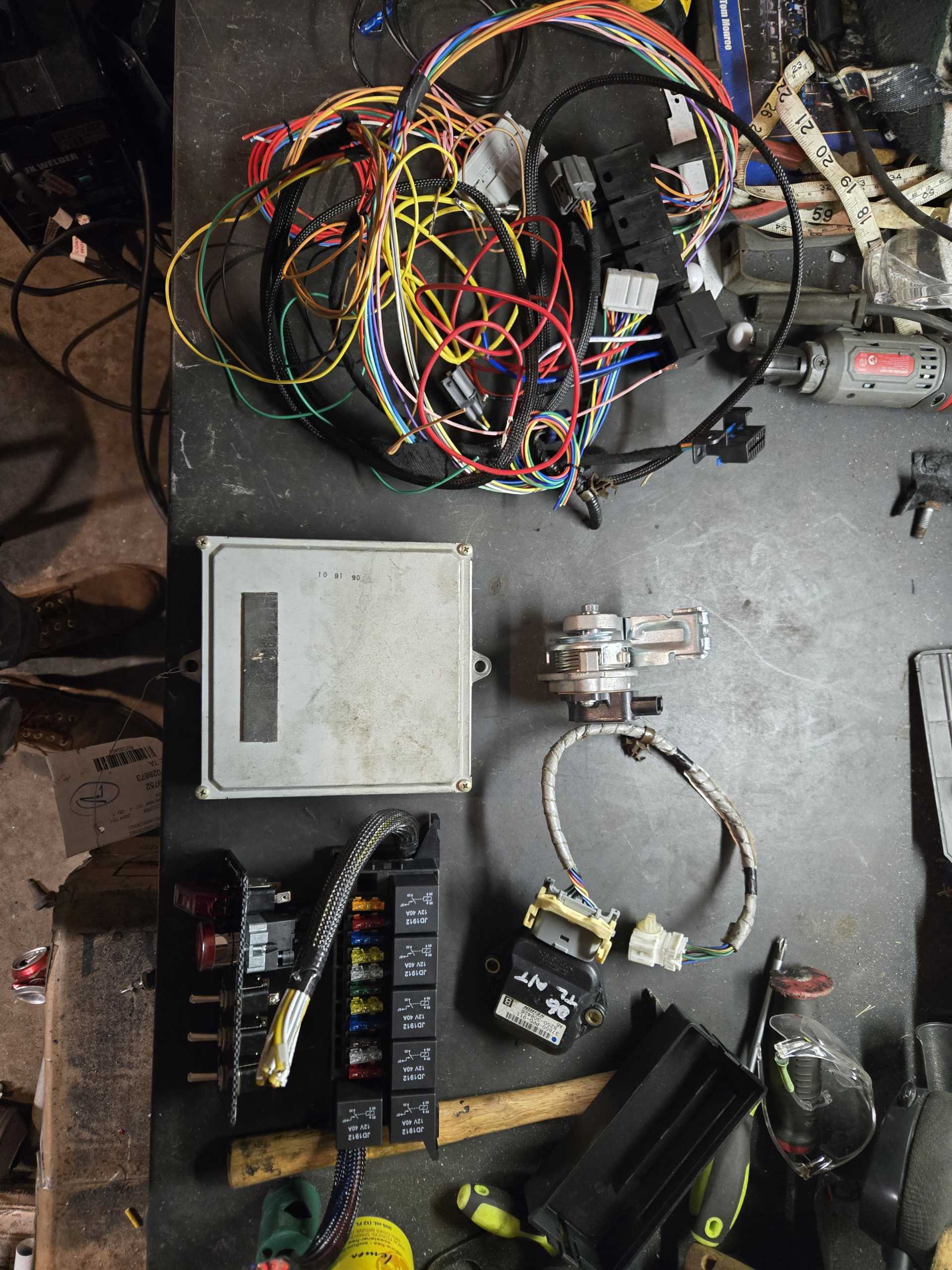

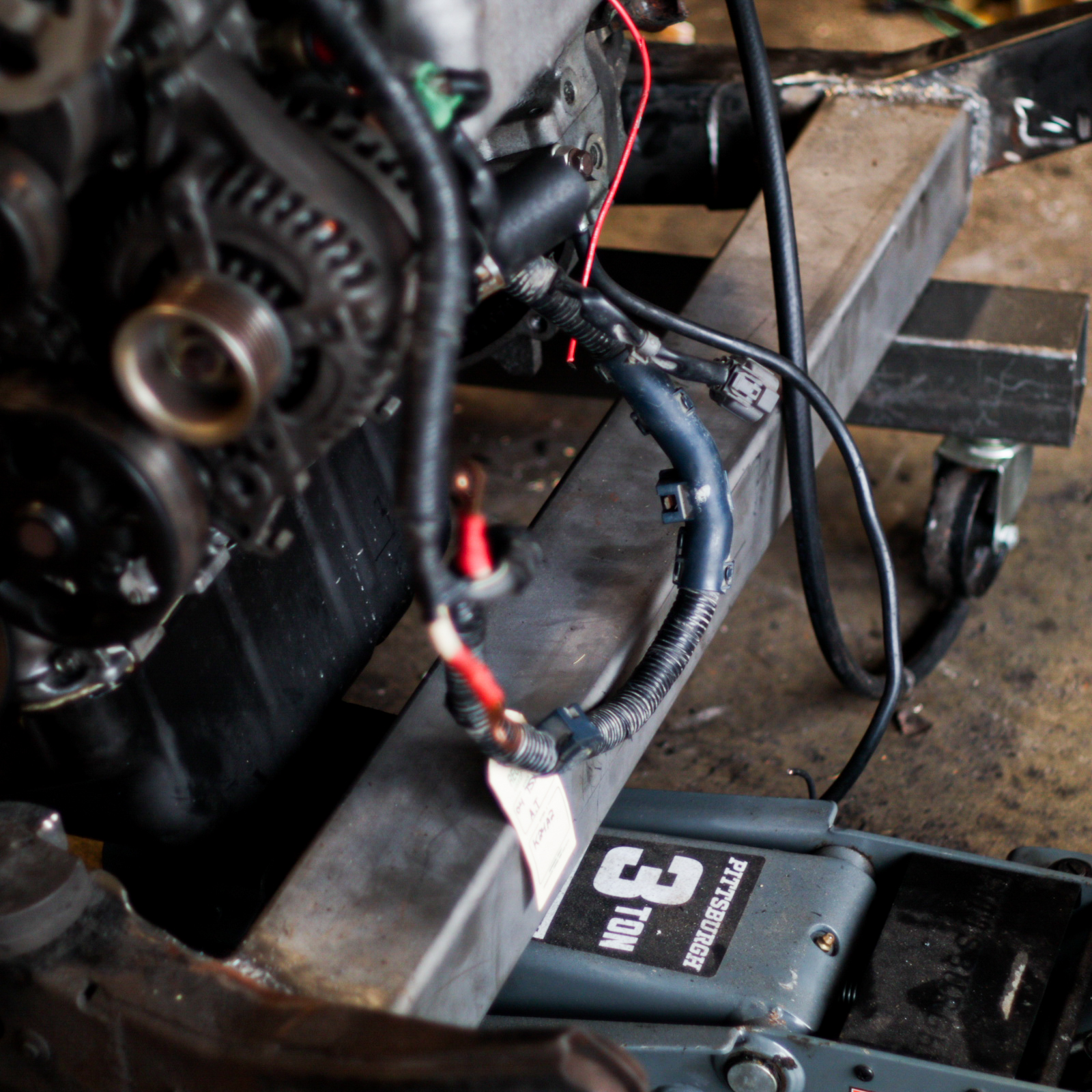

As of now I've pretty much compiled all of the parts needed to get the engine running on a stand. This includes a 2004 TSX ECU (ended up buying the wrong one but can still use it for testing) the electronic throttle position module, the throttle position sensor, starter, control panel, adapter harness, engine harness, and a fuse/relay block.

Since I am currently going as cheap as possible with this project, it also means I'm going as stock as possible. This is going to be a challenge for various reasons. The stock 2004 Acura TSX comes with an electronic drive by wire throttle body set up. Thankfully, it uses a cable to move the throttle position sensor in the engine bay rather then having one built into the pedal. I have to figure out a way to tie the Fieros stock throttle cable to the throttle position sensor. In the future, I plan on swapping in an Acura RSX drive by cable throttle body when I get the funds to get a K-pro ECU.

I've also replaced the Flywheel with an RSX flywheel since its almost 5 pounds lighter then the stock TSX flywheel, hopefully will improve the throttle response a little bit.

While all of this is fine and dandy Im having some huge issues trying to get power to the ECU when on the engine stand. The ECU harness I bought sadly did not come with a wiring diagram so I've been having to fiddle with stuff until it works, and it has been taking forever to get it done. its a literal rats nest and has been the worst part of this project.

the good thing is, once the engine runs and I know that it can run reliably without issues, most of the work of fabbing it into the car will, not be easy persay, but it will definitely be a nice change of pace compared to dealing with the electronic rats nest this engine needs.

hopefully next update I'll have the engine wired up and running. once that happens I'll be able to provide a much more in depth break down of the set-up I'm running.

UPDATE: 12/21/24

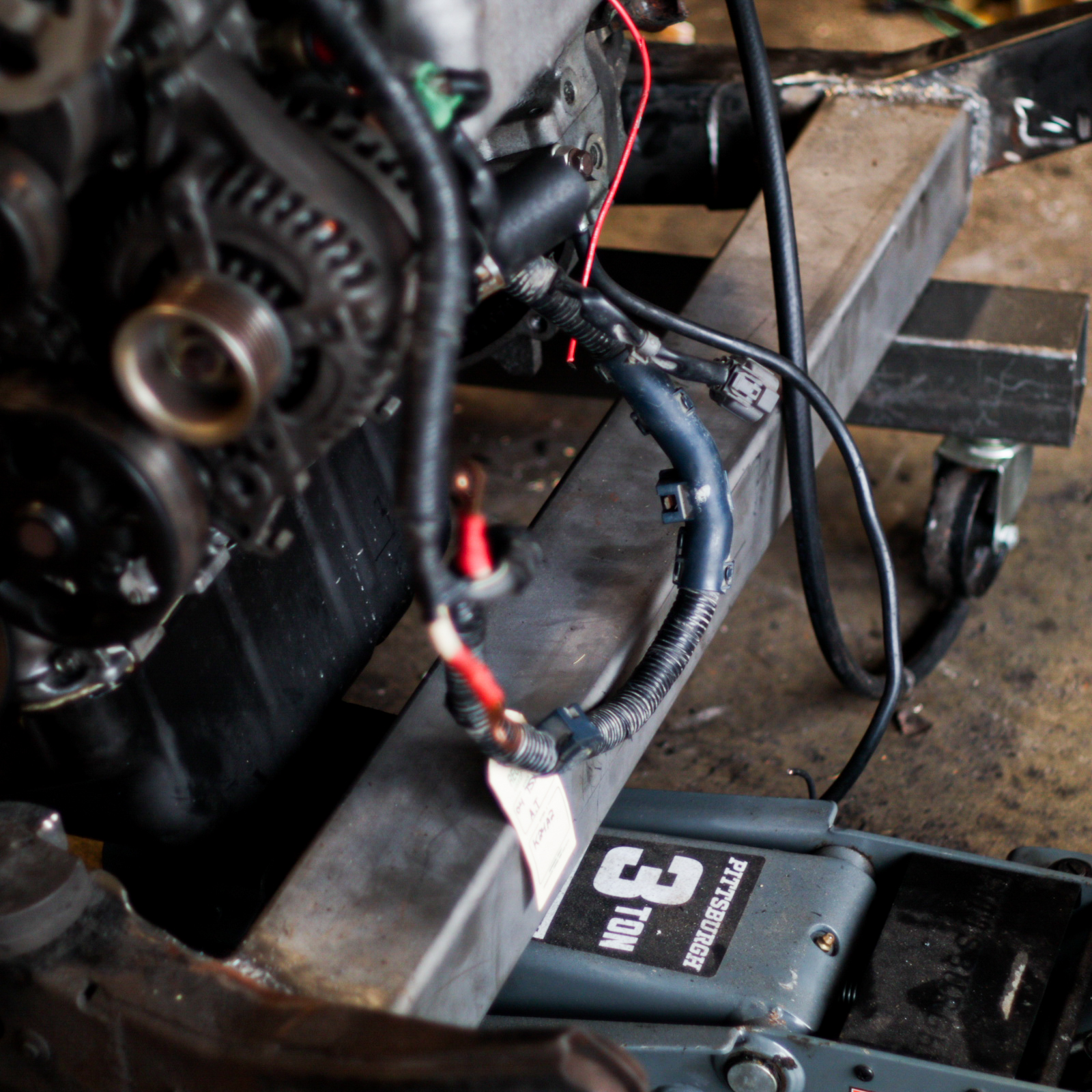

I got the engine running finally!!!!!

Video:

https://drive.google.com/fi...nHF/view?usp=sharingSo after dreading how I would get the engine running, I found a nice little company called Honda Tuning Suite (HTS)! Its a similar program to what Hondata and K pro offer but 1/4 the price ($200 for the license) and it allowed me to reflash and program the ECU. I was able to deactivate the Immobilizer, secondary O2 and dissable the transimssion saftey switches since Im running an automatic ECU on a manual car. Took a really long time to figure out but im finally moving onto the stage of mocking up the engine bay and getting the engine into the car.

Now that I am onto the stage of getting the engine into the car I need to know a few things and would like to ask some questions. My main question is how tall was the Iron Duke compared to the top of the subframe? I know I should have measured this when I pulled the duke out but im not great at looking ahead. The reason I need to know this is because the K24 is a DOHC engine, which makes it significantly taller than its cam in block OHV friend, the Duke. I know that GM already strugled to fit the duke in alone, and If i have to modify the deck lid a little bit I dont mind, as long as there is no noticeable difference cosmetically. I just need the engine to FIT.

My next question is does anyone know the optimal gap between the axle and subframe. Since the K series is going to be sunken pretty deep into the subframe in order to make up for the excess height, I dont want to go so low, that the axels end up colliding with the subframe as the suspention travels downwards.

Im also planning on adding a skid plate due to how low the engine will be compared to the subframe (I am NOT taking any chances with wild rocks on the road)

Update: Subframe finished! 3/10/25

Been quite awhile since I last updated but Ive been busy with school so I havent had much time to work on the car.

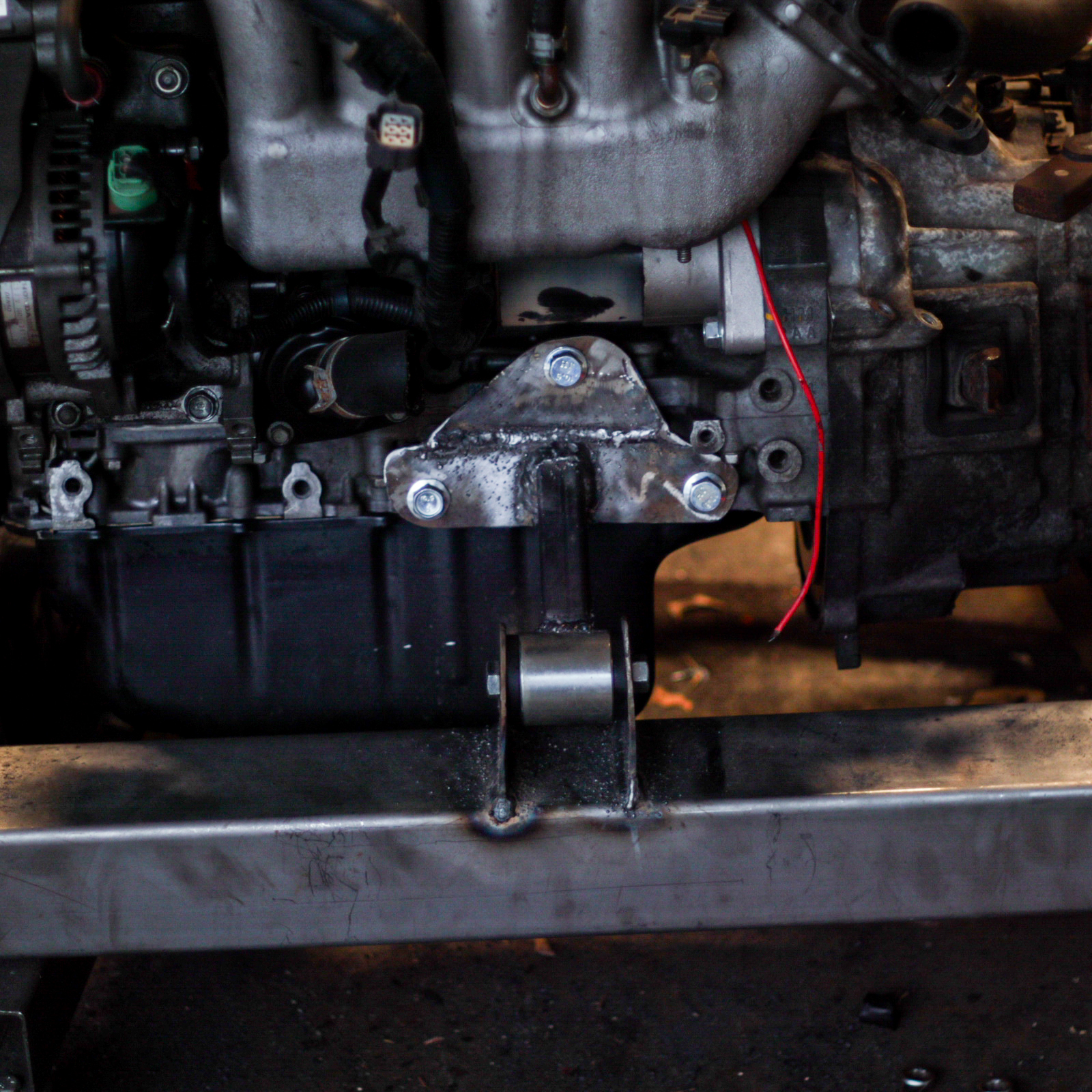

So far, ive gotten a new clutch installed and finished fabricating the subframe and engine mounts.

I based 90% of my work off opf Steven Vincents build so you can get much deeper explanations on his KFiero Youtube Channel.

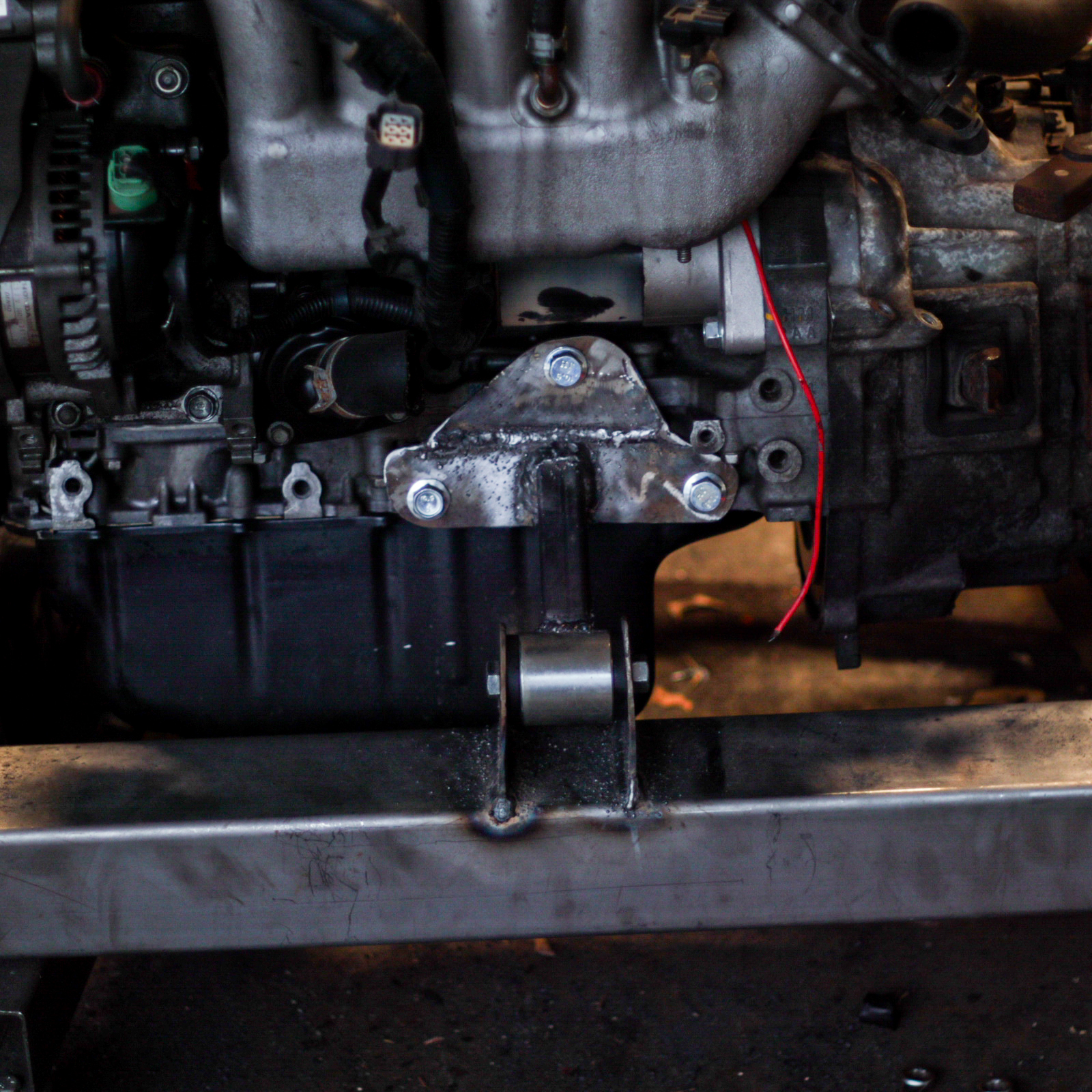

As far as changes to the subframe itself are concerned, I pretty much just cut the front most cross member, and welded a 3x3 steel tube 6 inches closer to the front bushing. The purpous of this was in ordfer to clear the larger oil pan, as well as the AC compressor that the K24 has. This also will help stiffen up the frame a bit with the thicker metal. I also ended up cutting the majority of the original engine mount brackets and exhaust hangers to better clean up the whole thing.

After that was finished I pretty much spent most of my time trying to line up the engine with the Fiero axle center line (eyeballed) as well as getting the 5 degree engine angle as close as possible (eyeballed)

I then made some engine mounts that, mind you have been properly gusetted and reinforced since thes photos were taken, I promise you they dont look like this anymore. The 2 mounts I have created are not meant for much load bearing as they are designed to deal with engine twist, and I will manufacture 2 more to hold the majority of the weight on the right and left of the engine in the near future. These mounts have not been made yet.

Once I PROPELY gusetted reienforced the mounts, I went ahead and rattlecanned the frame which tunred out like **** but it will work for now. Also installed new poly bushings

welp thats where im at right now. Im waiting on pressure plate bolts and wil hopefuloly put everything together within the next 2 weeks. As you can see, I am slowly setting myself up for failiure, but I dont care, because im impatient.

feel freee to **** on my work as you please

[This message has been edited by BruhMans06 (edited 03-11-2025).]