|

|

|

|

newest project by bubbajoexxx

| Started on | : 09-12-2003 06:18 PM |

| Replies | : 3111 (375502 views) |

| Last post by | : Trinten on 04-23-2023 11:02 PM |

|

|

|

|

Nov 30th, 2010

|

Erik

Member Posts: 5625

From: Des Moines, Iowa

Registered: Jul 2002

|

| | | quote | Originally posted by bubbajoexxx:

yes as only the radius was removed no material from the sides or depth |

|

| | | quote | Originally posted by bubbajoexxx:

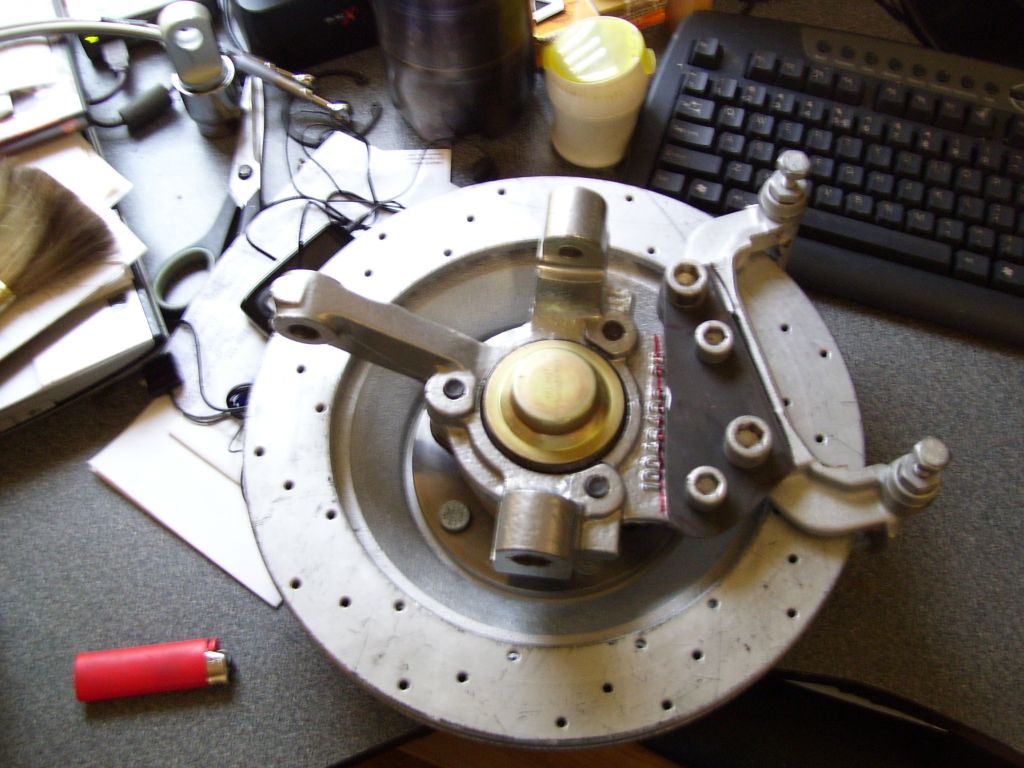

the spindles i use are not ball bearing spindle they are roller bearing spindles I only use the fiero bearing housing so there is no machine work done on the new spindle

and the axle size is 1/14 dia. the fiero is 1 inch in dia.

|

|

So it appears it is stronger with the increased shaft diameter and the bearings also being stronger. I am sort of concerned that it might be too strong and won't serve as a fuse of sorts to prevent other suspension components from becoming overloaded https://www.fiero.nl/forum/Forum2/HTML/108566.html from ebearing ... The engineering guys also wrestle with this question: if we make the bearings so they're not the point of failure, and instead the point of failure becomes the rotor flange or suspension mount, is that a design direction we want to go? The answer, of course, is no. [This message has been edited by Erik (edited 11-30-2010).]

|

01:14 AM

|

|

bubbajoexxx

Member Posts: 1630

From: Ontario Canada

Registered: Aug 2003

|

| | | quote | Originally posted by Erik:

So it appears it is stronger with the increased shaft diameter and the bearings also being stronger. I am sort of concerned that it might be too strong and won't serve as a fuse of sorts to prevent other suspension components from becoming overloaded

https://www.fiero.nl/forum/Forum2/HTML/108566.html from ebearing ... The engineering guys also wrestle with this question: if we make the bearings so they're not the point of failure, and instead the point of failure becomes the rotor flange or suspension mount, is that a design direction we want to go? The answer, of course, is no.

|

|

there is nothing more disasterous than loosing a wheel flange and wheel as you loose front brakes wheel bearings should not allow a wheel to become separated from the car at any time . and here is a note this is from a GM retired enginer i spoke with a few months ago about GM and chinesse parts he told me that in 87 GM started importing most of its bearing from china for use in GM cars as a cost savings they where bearings from top manufacturers that moved there plants to china (ie) FAG BORG WARNER SKF [This message has been edited by bubbajoexxx (edited 11-30-2010).]

|

11:28 AM

|

|

Erik

Member Posts: 5625

From: Des Moines, Iowa

Registered: Jul 2002

|

| | | quote | Originally posted by bubbajoexxx:

there is nothing more disasterous than loosing a wheel flange and wheel as you loose front brakes wheel bearings should not allow a wheel to become separated from the car at any time .

and here is a note this is from a GM retired enginer i spoke with a few months ago about GM and chinesse parts he told me that in 87 GM started importing most of its bearing from china for use in GM cars as a cost savings they where bearings from top manufacturers that moved there plants to china (ie) FAG BORG WARNER SKF

|

|

E bearing did mention that the stock wheel bearings usually give you fair warning they are beginning to fail, which serves as a fuse of sorts since the bearing is sacrificing itself to protect other suspension/ brake components . Since your mod appears much stronger I just wonder if loads that exceed the orignal design parameters of the stock suspension/ brake components will appear as cracks or stress risers that may not give any warning at all before failure.

|

04:21 PM

|

|

bubbajoexxx

Member Posts: 1630

From: Ontario Canada

Registered: Aug 2003

|

| | | quote | Originally posted by Erik:

E bearing did mention that the stock wheel bearings usually give you fair warning they are beginning to fail, which serves as a fuse of sorts since the bearing is sacrificing itself to protect other suspension/ brake components . Since your mod appears much stronger I just wonder if loads that exceed the orignal design parameters of the stock suspension/ brake components will appear as cracks or stress risers that may not give any warning at all before failure. |

|

from what i have read the bearing is not what fails its the wheel flang separating from the axle and what i built will fail like any other bearing if not maintained the bearings are the same size as stock just a better bearing not plastic but metal caged

|

06:41 PM

|

|

Erik

Member Posts: 5625

From: Des Moines, Iowa

Registered: Jul 2002

|

| | | quote | Originally posted by bubbajoexxx:

from what i have read the bearing is not what fails its the wheel flang separating from the axle and what i built will fail like any other bearing if not maintained the bearings are the same size as stock just a better bearing not plastic but metal caged |

|

Yeah I plan on using your mod for my N* powered Fiero if you don't mind. What grease are you using for the bearings? Also what torque value on the nut? [This message has been edited by Erik (edited 11-30-2010).]

|

07:25 PM

|

|

Fiero2m8

Member Posts: 1928

From: Niagara, Ontario, Canada

Registered: Feb 2006

|

| | | quote | Originally posted by RCR:

Thanx Ryan,

What threw me was my original cradle not having the pin. I didn't realize the chassis had the holes until I crawled under to remove the back cross member.

Second question...Back cross member...It doesn't look like anyone puts it back in...I was looking at it and it doesn't seem structural, but as a gaurd for the gas tank. Any concern not having it?

thanx again...

Bob

|

|

Bob, First of all, glad you found the locating pin hole in the frame - should make sense now. Back cross member - stock 88 doesn't have one, probably because crossmember mounts back there instead. The 88 crossmember is beefier and have 8 bolt locations vs. the 84-87 having 4 bolts. Here's a pic of 88 courtesy of LT188GT:

|

10:13 PM

|

|

Fiero2m8

Member Posts: 1928

From: Niagara, Ontario, Canada

Registered: Feb 2006

|

I got the intermediate steering shaft exchanged for the swap: (The 88 is shorter than the 84-87)    Also reinstalled the C3 Corvette master cylinder:  88 Steering rack bolted in with all new premium tierods ends, upper and lower ball joints: Everything torqued to spec and any reused hardware will be detailed later:  Slowly but surely starting to reassemble this Indy... [This message has been edited by Fiero2m8 (edited 11-30-2010).]

|

10:30 PM

|

|

bubbajoexxx

Member Posts: 1630

From: Ontario Canada

Registered: Aug 2003

|

| | | quote | Originally posted by Erik:

Yeah I plan on using your mod for my N* powered Fiero if you don't mind. What grease are you using for the bearings? Also what torque value on the nut?

|

|

castrol heavy duty wheel bearing grease sold in tubs you dont torque the nut you tighten till snug the turn back 1/4 turn to give you the correct pre load

|

10:38 PM

|

|

|

Dec 1st, 2010

|

Erik

Member Posts: 5625

From: Des Moines, Iowa

Registered: Jul 2002

|

| | | quote | Originally posted by bubbajoexxx:

castrol heavy duty wheel bearing grease sold in tubs

you dont torque the nut you tighten till snug the turn back 1/4 turn to give you the correct pre load |

|

Thanks for the info BubbaJoe, I figured it might be old school ( like on a front spindle of a typical rear drive vehicle) regarding the nut tightness and preload. This looks like a great solution regarding 88 hub replacement.

|

02:36 AM

|

|

Fiero2m8

Member Posts: 1928

From: Niagara, Ontario, Canada

Registered: Feb 2006

|

|

Gokart Mozart

Member Posts: 12143

From: Metro Detroit

Registered: Mar 2003

|

|

05:55 PM

|

|

|

PFF

System Bot

|

|

|

Dec 2nd, 2010

|

Nexus

Junior Member Posts: 7

From: Sud. Ont. Can

Registered: May 2010

|

| | | quote | Originally posted by Fiero2m8:

Here's a first look at my new paint

|

|

That paint is going to look sweet on the whole car!!! Good choice for sure

|

09:32 AM

|

|

|

Dec 4th, 2010

|

Nilknarf

Member Posts: 289

From: Bristol, IL, USA

Registered: Jan 2008

|

Bubbajoe,

How much would you charge to make a set of these modified front hub bearings?

|

12:58 PM

|

|

doublec4

Member Posts: 8289

From: Oakville, Ontario, Canada

Registered: Jun 2003

|

|

BlackThunderGT

Member Posts: 2048

From: The Rock

Registered: Apr 2009

|

| | | quote | Originally posted by doublec4:

Paint looks good! I'm excited to see this thing come together. Exciting stuff!

|

|

X2

|

05:45 PM

|

|

|

Dec 6th, 2010

|

Fiero2m8

Member Posts: 1928

From: Niagara, Ontario, Canada

Registered: Feb 2006

|

Thanks guys, it's the colour I've been after for a few years now and will be unique on a Fiero. My apologies to the die hard Indy fans, but let's face facts that it's far from original stock. I took a few pictures of what it looks like in natural sunlight.    Bubbajoe - I will drop by this Thursday afternoon if the brackets are going to be ready.

|

11:55 PM

|

|

|

Dec 7th, 2010

|

johnyrottin

Member Posts: 5496

From: Northwest Florida

Registered: Oct 2007

|

That is going to look amazing!

|

06:32 AM

|

|

|

Dec 10th, 2010

|

Fiero2m8

Member Posts: 1928

From: Niagara, Ontario, Canada

Registered: Feb 2006

|

Finished up installing the poly bushings in the C5 rear control arms. They had to be pressed in due to the one piece design. Then the sleeves and washers go in.  Continuing to focus on the front compartment though and I was mocking up where the universal conderser and fan is going to be located. I want to maximize potential storage space now and I have a little extra space since the stock rad was removed.   Next I noticed what a bonehead I can be while test fitting the sway bar:  "How's the zero latch sway bar links gonna reach the UCL...  Ah crap, I powder coated the wrong sway bar"  That bar was from the rear of the 86 Roadster  Only saving grave was I found the 88 bar in the Fiero room sandblasted and primered. It is the 28mm bar I knew I had so I just decided to paint it instead.

|

04:52 PM

|

|

RCR

Member Posts: 4416

From: Shelby Twp Mi

Registered: Sep 2002

|

Looks great Ryan...except for the early sway bar...   Bob PS: hopefully I'll be cutting metal for the front swap this weekend...

|

05:10 PM

|

|

|

Dec 11th, 2010

|

bubbajoexxx

Member Posts: 1630

From: Ontario Canada

Registered: Aug 2003

|

|

|

Dec 12th, 2010

|

RCR

Member Posts: 4416

From: Shelby Twp Mi

Registered: Sep 2002

|

| | | quote | Originally posted by Fiero2m8:

Update for fieroguru:

After some more R&D we are going to mod Bearing #513009 instead due to its smaller size 2.79" vs. 88 spindle of 2.74"

Timken or FAG #513009

Cross Ref #7466902 7470539 7470540

Non-Drive (FWD)

REAR w/Disc Brakes

Non-ABS

Fits:

1979-1985 Buick Riviera

1979-1985 Cadillac Eldorado

1980-1985 Cadillac Seville

1979-1981 Oldsmobile Toronado

1982-1985 Oldsmobile Toronado

http://www.alibaba.com/prod...eel_unit_513009.html

|

|

Ryan/Joe: Is there an application that uses the similar bearing but with the 5x115 or 5x4.5" pattern? I'd like to use one or the other... Bob

|

08:15 AM

|

|

|

PFF

System Bot

|

|

|

|

bubbajoexxx

Member Posts: 1630

From: Ontario Canada

Registered: Aug 2003

|

| | | quote | Originally posted by RCR:

Ryan/Joe: Is there an application that uses the similar bearing but with the 5x115 or 5x4.5" pattern? I'd like to use one or the other...

Bob |

|

86 and up caddy rear bearing buick riv olds 88 5X115 BEWARE most GM replacement bearings even oem come from china and you want USA made only [This message has been edited by bubbajoexxx (edited 12-12-2010).]

|

10:02 AM

|

|

Nilknarf

Member Posts: 289

From: Bristol, IL, USA

Registered: Jan 2008

|

BubbaJoe,

Ever think about making these bearings for anyone else with 88's?

|

11:36 AM

|

|

RacerX11

Member Posts: 288

From: Peoria, IL

Registered: Feb 2003

|

| | | quote | Originally posted by bubbajoexxx:

86 and up caddy rear bearing buick riv olds 88 5X115

BEWARE most GM replacement bearings even oem come from china and you want USA made only |

|

I have a Timken made in USA rear 115mm hub (PN 513018, bucik/riv/olds 88 application), and unfortunately it uses ball bearings like the imports, not rollers. What brand hub assembly did you use?

|

04:54 PM

|

|

RCR

Member Posts: 4416

From: Shelby Twp Mi

Registered: Sep 2002

|

|

05:16 PM

|

|

RCR

Member Posts: 4416

From: Shelby Twp Mi

Registered: Sep 2002

|

| | | quote | Originally posted by bubbajoexxx:

86 and up caddy rear bearing buick riv olds 88 5X115

BEWARE most GM replacement bearings even oem come from china and you want USA made only

|

|

Thank you, sir...Another question... It would appear that your system is now rebuildable, ie, just buy the roller bearings from Timken. If that's so, it seems it would be inexpensive to buy the salvage yard hubs, buy new bearings, and rebuild the Fiero units with the new guts...Thoughts?? Bob

|

07:35 PM

|

|

|

Dec 13th, 2010

|

Fiero2m8

Member Posts: 1928

From: Niagara, Ontario, Canada

Registered: Feb 2006

|

| | | quote | Originally posted by bubbajoexxx:

come and get um |

|

Thanks Joe, I'm going to come tomorrow afternoon as I'm working on the project Tuesday evening this week. Then I can have them installed by Wednesday. Ryan [This message has been edited by Fiero2m8 (edited 12-13-2010).]

|

12:40 PM

|

|

|

Dec 18th, 2010

|

Fiero2m8

Member Posts: 1928

From: Niagara, Ontario, Canada

Registered: Feb 2006

|

|

12:31 PM

|

|

RCR

Member Posts: 4416

From: Shelby Twp Mi

Registered: Sep 2002

|

Ewww!! Ahhh!!! Shiney  Looks great Ryan. Bob

|

01:43 PM

|

|

|

Dec 19th, 2010

|

fieroguy123

Member Posts: 1523

From: Indianapolis

Registered: Sep 2009

|

|

bubbajoexxx

Member Posts: 1630

From: Ontario Canada

Registered: Aug 2003

|

OK Ryan I want to see more done now Im the slave driver I want to see some pannels applied

|

08:48 PM

|

|

|

PFF

System Bot

|

|

|

Dec 21st, 2010

|

Fiero2m8

Member Posts: 1928

From: Niagara, Ontario, Canada

Registered: Feb 2006

|

| | | quote | Originally posted by bubbajoexxx:

OK Ryan I want to see more done now Im the slave driver I want to see some pannels applied |

|

Yes I know! Tonight I'm working on the front sway bar install and front trunk. Order of reinstall is: 1. front suspension 2. rear suspension 3. powertrain 4. body 5. interior Guys if you've never removed a Fiero body before, Boomtastic has a good video here - click on "how to" section: http://boomtastic.com/media/myWimpy.htmlThis was my disassembly order, so my install panel order is roughly the reverse of this - need to pickup the rest of the panels first when I can borrow a pickup truck. Marker lights Side moldings Wheel well liners Rocker panels Taillights’ Rear hatch Rear bumper cover Front bumper cover Front hood Front fenders Seat belts B-pillar interior trim Headliner accessories Headliner Sail panels Roof Rear quarter panels Rear clip Inner door panels Mirrors Outer door panels BTW - My goal is to drive the newest project to Watkins Glen racetrack next April 2011 with the SOFA/GTA and Western NY members. If I'm behind schedule, feel free to call me out on that here. I may need to take some vacation time to achieve my goal since I'm working solo on it two evenings a week  ------------------

Indy Northstar-Stretch ~ LT1-NOS Roadster

|

02:42 PM

|

|

Fiero2m8

Member Posts: 1928

From: Niagara, Ontario, Canada

Registered: Feb 2006

|

| | | quote | Originally posted by fieroguy123:

I LOVE THAT PAINT! But of course I should because its identical to what's on my Formula ;-) I did a base/clear with jet black base and a pich of gold glass in the clear coat. It looks AMAZING in the sun!

|

|

Yeah the MICA is in the base coat for me but yes it really shows in bright light (sun or flash) as shown here:  Nice to have a fan of it, Cheers Fiero2m8 [This message has been edited by Fiero2m8 (edited 12-21-2010).]

|

02:49 PM

|

|

Fiero2m8

Member Posts: 1928

From: Niagara, Ontario, Canada

Registered: Feb 2006

|

Last night I got the poly bushings modified for an 88 front suspension. As many 88 parts are made of unobtainium, some tweaking was required. Discussion on the issue can be found here: https://www.fiero.nl/forum/Forum1/HTML/083626.htmlSince I am using the Formula/GT bar (28mm vs. 23mm), I purchased the largest size universal poly bushing (25mm) that comes in the small bracket size for frame clearance. I will have to bore out to 28mm to fit my 1988 Formula/GT sway bar. The 28mm poly comes in a larger size bracket that does not line up with the cradle holes and interferes clearance to the frame rails (no flat side like the stock bracket). http://cgi.ebay.com/ebaymot...&hash=item588b5e7b33http://www.energysuspension...ay-bar-bushings.htmlWarning, this is not easy to do without damaging the bushing as there is little room for error - use a lathe or drill press like I did to be successful. Here are the pics: The plan:   Stock bushings:  Bored Energy Suspension poly bushing:  Side by Side comparison:  This is how I solved getting a universal poly bushing w/bracket to be a bolt on application for a 28mm swaybar.

|

03:12 PM

|

|

|

Dec 22nd, 2010

|

Fiero2m8

Member Posts: 1928

From: Niagara, Ontario, Canada

Registered: Feb 2006

|

|

05:01 PM

|

|

|

Dec 30th, 2010

|

Fiero2m8

Member Posts: 1928

From: Niagara, Ontario, Canada

Registered: Feb 2006

|

Happy Holidays everyone. I haven't been able to work the the project much this week (remodelling mainfloor bathroom). I did however get the manifold done - thanks Bubbajoe for the brass

|

09:55 PM

|

|

bubbajoexxx

Member Posts: 1630

From: Ontario Canada

Registered: Aug 2003

|

nice job on the pcv manifold

|

10:43 PM

|

|

|

Dec 31st, 2010

|

Eau_Rouge

Member Posts: 208

From: Ontario, Canada

Registered: Jan 2007

|

Wow Ryan, looking very nice!

|

11:24 PM

|

|

|

Jan 1st, 2011

|

RCR

Member Posts: 4416

From: Shelby Twp Mi

Registered: Sep 2002

|

Ryan, BY the looks of these two pics, I'm wondering if there is enough clearance for the coolant tubes. It looks like they may hit the frame rails.. Have you fit them in yet? Bob [This message has been edited by RCR (edited 01-01-2011).]

|

04:58 PM

|

|

bubbajoexxx

Member Posts: 1630

From: Ontario Canada

Registered: Aug 2003

|

|

can't wait to see the whole car!

can't wait to see the whole car!