Fuel tank is back in and pumping gas. All the battery, ignition and ground feeds to the ECM/TCM checked out, so I hooked up HPtuners and did the initial download of the ecm/tcm calibration and worked up a base tune with the following changes...

VATS 1 and VATS 2: both set to Disable. This "should" turn off VATS

MAF Air Flow Frequency (Low): Compared to 07 Vette Table (same MAF I am using) and copied it, then confirmed the difference was 0. For MAF change

MAF Air Flow Frequency (High): Compared to 07 Vette Table and copied it, then confirmed the difference was 0. For MAF change

Injector Flow Rate vs. Pressure: Compared to 07 Vette Table and copied it, then confirmed the difference was 0. For Injector change

Tach Output- Tach Type. Originally was set for serial, the TBSS was Frequency so I changed it to Frequency. I "hope" this will enable the direct tach output like the TBSS has

ETC Scalar - Change to 4725 for 90mm TB

Effective Area Max - Changed to 8191 for 90mm TB

Effective Area Min - Changed to 0

Effective Area Min Fail - Changed to 5

RPM Limits - Extreme Cutoff - Changed to 6800

RPM Limits - Extreme Resume - Changed to 6720

Cutoff RPM vs. Gear - Changed all values to 6800

Cat Over Temp Protection: Disabled. I don't have a cat and this adds 25% fuel to protect the cat under certain conditions

Displacement On Demand: Disabled - it need to be off for all tuning. I will turn it back on at a later date

DoD RPM Thresholds - Min RPM: Changed to 1600 rpm. I only want it to work in 5th/6th gears between 45 and 80 mph

DoD RPM Thresholds - Max RPM: Changed to 2300 rpm. I only want it to work in 5th/6th gears between 45 and 80 mph

DoD Enable VSS: changed to 45 mph

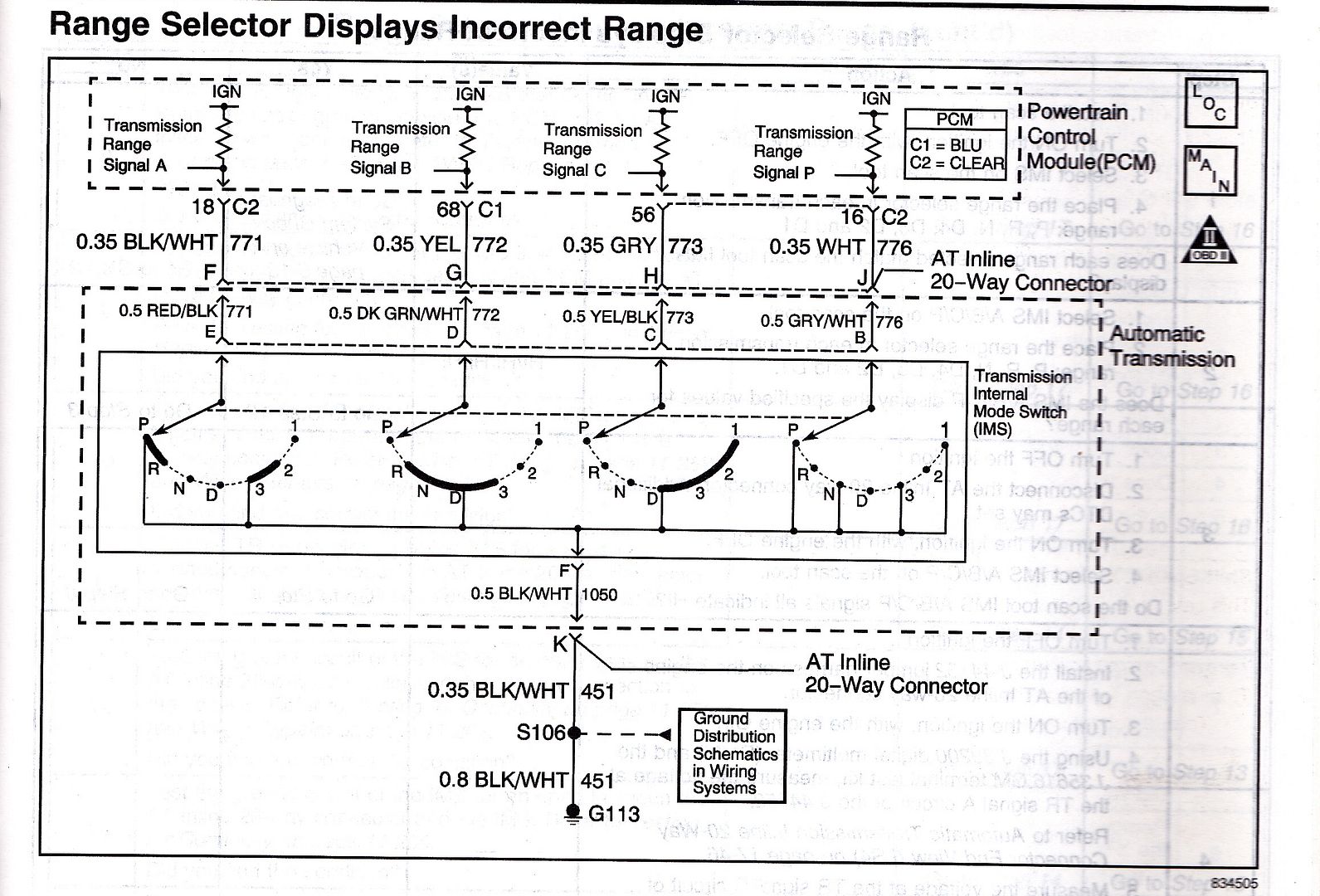

DoD Disable vs PRNDL: D4 was 0, so I changed everything to 0 so DoD shouldn't care what the range switch says, even though the TCM is hard wired to show D4

DoD Disable vs Gear: 3rd gear and 4th gear were set to 0, so I changed 3rd gear to 1 and 5th and 6th gears to 0. No idea if this will work, but I changed it anyway

Engine Torque Management Spark: Disabled. I don't want any torque management

Engine Torque Management ETC: Disabled. Same reason

Transmission Diff Score: Disabled

Transmission Abuse Mode Torque Reductions vs. RPM: Set every value to 0 - no torque reductions

Transmission Abuse Mode Torque Reductions Duration vs. transmission temp: Set every value to 0 - no torque reductions

Starter Diag: Disabled. Using Fiero starter control

Clutch Interlock: Disabled. Using Fiero clutch pedal wiring

Number of Fans: Set to 1

Ignition off run time: set to 60 seconds. Reduced from 360 seconds due to my smaller battery

Speedometer - Tire Size: Set to 24.6

Speedometer - Gear Ratio: set to 3.55. F40 final drive ratio

Speedometer - VSS PP Rev: set to 78. # of teeth for F40 VSS

Speedometer - VSS PP Rev - Trans: set to 78. # of teeth for F40 VSS

Speedometer - VSS PP Mile: set to 63949

Speedometer - Revs per Dist (1 mile): Set to 819.86

Speedometer - Revs per Dist (1 mile) - trans: Set to 819.86

Speed Limiter (fuel cut off): Changed to 200mph

Speed Limiter 2 (fuel cut off): Changed to 200mph

The below Diagnostic Trouble Codes were turned off for missing components from the installation (Evap, Fuel Pressue, Post Cat O2 sensor, Cat, etc)

P0036 - HO2S Heater Control Circuit Bank 1 Sensor 2 - Turned off

P0054 - HO2S Heater Resistance Bank 1 Sensor 2 - Turned off

P0137 - HO2S Circuit Low Voltage Bank 1 Sensor 2 - Turned off

P0138 - HO2S Circuit High Voltage Bank 1 Sensor 2 - Turned off

P0140 - HO2S Circuit Insufficient Activity Bank 1 Sensor 2 - Turned off

P0141 - HO2S Heater Performance Bank 1 Sensor 2 - Turned off

P0420 - Catalyst System Low Efficiency - Turned off

P0422 - Evaporative Emission System Small Leak Detected - Turned off

P0443 - Evap Purge Solenoid Valve 1 Control CKT - Turned off

P0446 - Evap Vent Solenoid Valve Control System - Turned off

P0449 - Evaporative Emission Vent Solenoid Control Circuit - Turned off

P0451 - Evaporative Emission Control System Pressure Sensor Range - Turned off

P0452 - Fuel Tank Pessure Sensor Circuit Low Voltage - Turned off

P0453 - Fuel Tank Pessure Sensor Circuit High Voltage - Turned off

P0454 - Evaporative Emission Control System Pressure Sensor Intermittent - Turned off

P0455 - Evaporative Emission System Leak Detected - Turned off

P0461 - Fuel Level Sensor Performance - Turned off

P0462 - Fuel Level Sensor Circuit Low Voltage - Turned off

P0463 - Fuel Level Sensor Circuit Low Voltage - Turned off

P0464 - Fuel Level Sensor Circuit Intermittent - Turned off

P0481 - Cooling Fan Relay 2 Control - Turned off

P0496 - Evaporative Emission System High Purge Flow - Turned off

P2544 - Torque Management Request Input Signal A - Turned off

P2A01 - O2 Sensor Circuit Range/Performance Bank 1 Sensor 2 - Turned off

Once all these changed were saved, I did a Write Entire to the ECM/TCM.

After I pulled the plugs and cranked the engine to build up oil pressure, I had several DTC's.

0315 - needs a case learn - need to have the engine running to perform it, but some say you can do it with a manual transmission. This will wait till it is running

0340 - Camshaft Sensor - need to run through the sensor/harness diagnostics on this one. Wiring, sensor or ECM issue

0557 - Brake Booster Sensor. I didn't have the connected plugged in

1516 - TAC Control - need to run through the sensor/harness diagnostics on this one. Wiring, Throttle Body or ECM issue

2101 - TAC Control - need to run through the sensor/harness diagnostics on this one. Same as above.

When I tried to start the engine after revision 2 of the tune, the fuel pump primed for about 1/2 second (should be 2 seconrs) then shuts off. The engine cranks without starting... I need to listen better to see if the fuel pump is working while it is cranking and check for spark at the coils. I suspect it is due to the cam sensor issue and the engine not knowing which cylinder is ready for fuel/ignition.

I am please that the mini battery has been able to spin this engine quite a bit to both prime the oil (about 1 minute of cranking) and to crank the engine (for another minute or two).

[This message has been edited by fieroguru (edited 02-05-2013).]