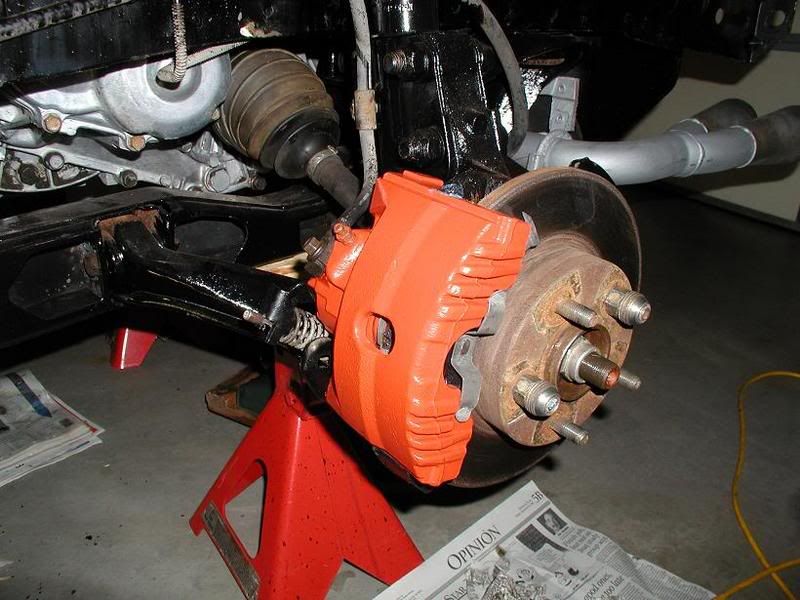

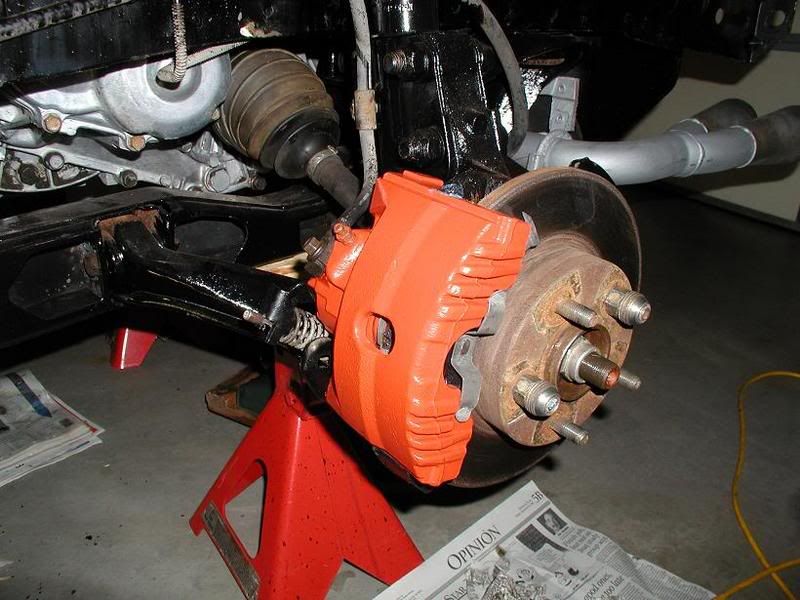

Ok to continue from the Front brake post:

https://www.fiero.nl/forum/Forum9/HTML/000036.htmlHave completed the Rear's and am ready to fill and purge and check and see if the rebuilds work.

But first a little info for you all.

I will not go into the pins and pin guides since they are the same as the front post. But I'll say again, if your putting in new pads, clean and lude the pin bores with lots of brake grease.

First the rear caliper break down.

The large spring goes inside the pistion and assist the ebrake funtion.

The pistion is the interesting part and is the key to the ebrake.

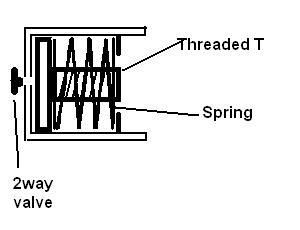

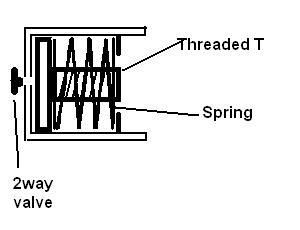

The inside of the piston contains a top hat shaped threaded section for the screw which is spring loaded. This acts like a slip clutch so that the screw will adjust as the pads wear. When you use the brakes the ebrake screw does not move but the pistion will. As it moves out it would want to turn on the screw but can't since the pistion is locked into the pad by the two pins. (That's why it's important to have the pistion turned for the pad pins fit the pistion holes) Instead the threaded T in the piston is pulled away for for the inside face of the piston compressing the spring (NOT the large piston spring in the pic above) that tries to keep it pressed against the piston face. This reduces the friction holding it in place and allows it to turn on the screw as it returns to it's place against the piston face. So if all works right your ebrake should stay in adjustment.

Here are the parts that come in the rebuild kits.

Note: The screw seal is just setting inside the thrust washer.

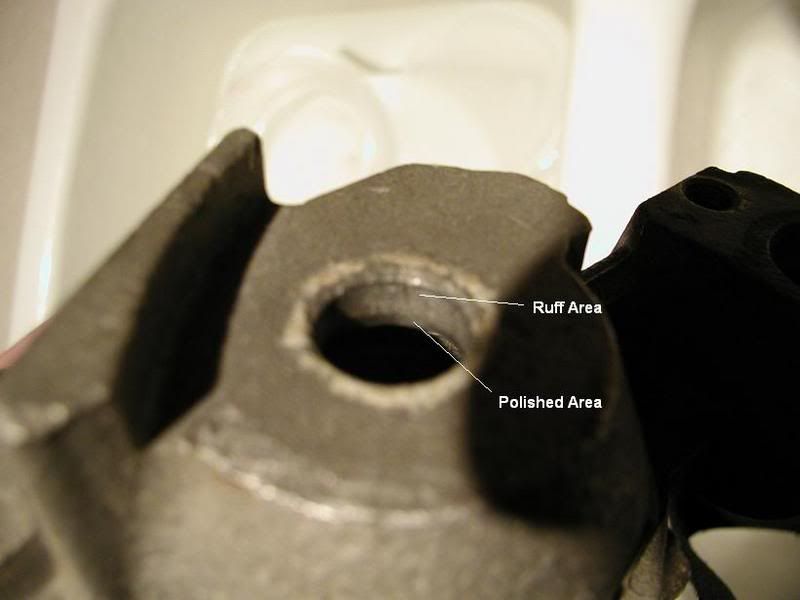

Since the pistion is metal and (in my case good shape) I did not have to do anything to the pistion. I did polish the bore a little as it was not machined as nice as the fronts where.

There are three key places that caliper will leak from.

The first of course is the pistion seal.

The second is the screw shaft seal.

The third is the two way valve in the face of the pistion. More on this later.

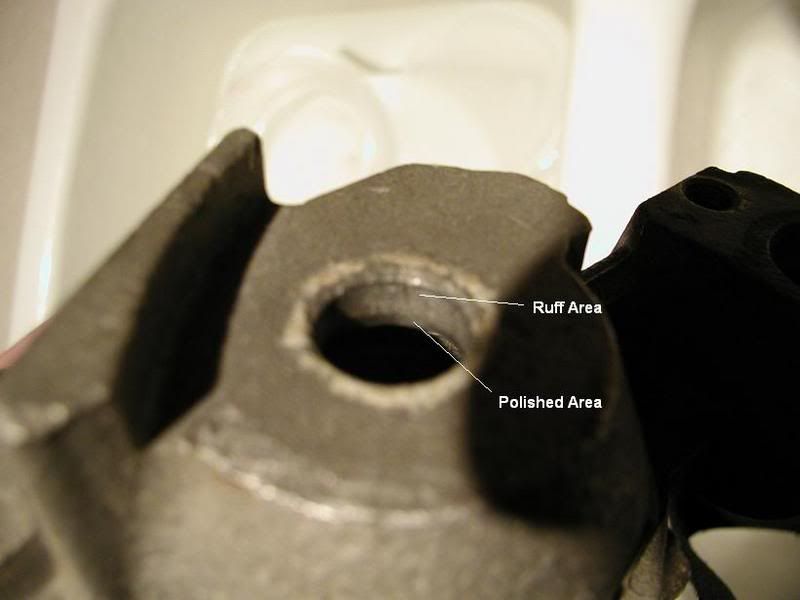

When I looked at the hole where the screw passes thru the rear of the caliper I notice the hole was not very smooth except in the very inside edge.

Found it interesting that when you put the screw into the hole the seal does not ride in the polish area but about in the middle of the ruffer area. I polished the hole more and hopfully will allow the seal to work better. (or make it leak more will see)

Now the two way valve.

In the face of the pistion behind the pad is a very soft small botton that presses into a hole in the pistion. Took me a bit to figure out what this might be for. Here is my idea, maybe someone will correct me if I'm wrong.

As I described above the threaded T part inside the piston has to move in and out a small amount as it adjust. when it does it has to pull away from the inside face of the piston. Since the pistion is full of brake fluid as it pulls away there would be a suction formed that would fight the pistion moving out. the small button would allow the suction to be broke as it flexes in. A small amount of brake fluid would then be between the face and the T. The button would flex outward a little as the fluid works it's way around the T back into cyl. On one of the calipers this button had become rock hard and most of it was broke off. Fluid had been leaking from the hole for sometime. You can see the yellow botton in the parts bag.

The process is basically take it apart, clean it up and put it back together with the new parts. Getting the pistion back in is a little more of a trick due to the large spring that goes inside the piston. I installed the piston by hand far enough to get a small piece of wood between the piston and the outside edge of the caliper. Then used a bar clamp to press the piston back in. You place a socket over the hole the screw has to come out as you press it in. After I had the piston started I ended up putting the pawl onto the screw and working back and forth between pressing the piston in and working the screw in.

Total cost $3.50ea.

Well there you have it. Hope it all works.